Video

1 / 4

Export to Cambodia Planetary Concrete Mixer

Options:

- model

- JN100

- application

- concrete mixer

| Model No. : | Export to Cambodia Planetary Concrete Mixer |

|---|---|

| Brand Name : | SIMAMIX |

| Applicable industry : | Machinery Repair Shops,Other |

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Product description

DESCRIBE

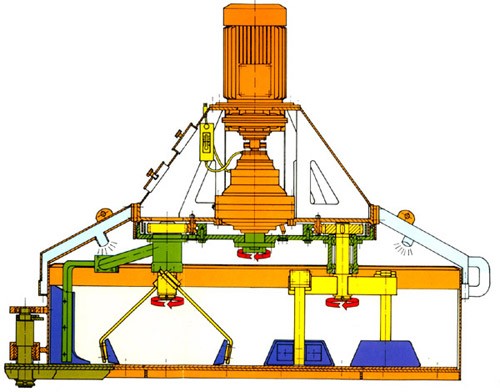

The JN planetary mixer is a concrete mixer machine that adopts the new concept of counter-current mixing and makes new breakthroughs based on the advantages of traditional planetary concrete mixers. It has excellent mixing performance, high efficiency, and low energy consumption, and offers multiple rotating speed configurations, optimized mixing devices, and comprehensive safety guarantees. This planetary concrete mixer design also features a unique gearing system. The JN series of planetary mixers are different from HZS series concrete mixer plants, such as hzs25 concrete batching plant, hzs35 concrete batching plant, and hzs60 concrete batching plant, in terms of shape and production scale, but their working principle is roughly the same. Other concrete mixers, like the automatic mini concrete mixer, electric mini concrete mixer, mini cement mixer drum, diesel concrete mixer pump, concrete mixer diesel engine, electric concrete mixer, big capacity concrete mixer, mobile concrete mixer, hydraulic hopper electric, twin shaft concrete mixer, and twin shaft mixer batching plant, are also available on the market with varying features and prices.

FEATURE

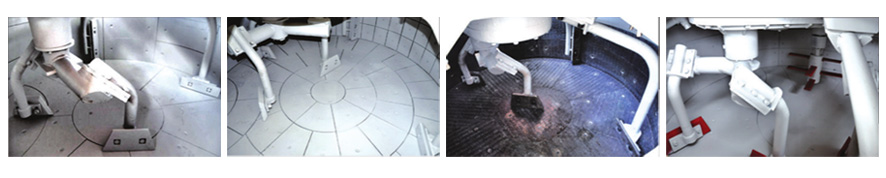

Excellent mixing performance

The rotating direction of mixing stars is reversed with the revolution direction, and each mixing star’s direction is also different. There are both circulation movement and convective movement during material mixing, which makes the material severely mixed. The counter current and impact prevent material from agglomeration and thoroughly mixed and achieve the uniform distribution in microcosm.

High mixing efficiency, low energy consumption

The new concept of counter-current mixing makes the mixing tracks more complex, mixing effects more severe and effective. In the condition of same material proportion and same feeding order, the innovated planetary mixer’s mixing time is shortened by 15-20% compared to traditional models. The innovated power driving design and optimized mixing device are of high transmission efficiency; both the no-load current load current are lower by 15-20% compared to traditional planetary mixers.

Optimized mixing device design

Optimized mixing blades and installation angle, and improved mixing arm make the mixing motion more effective; the load distribution of gearing system is more reasonable, the discharging faster and cleaner, effectively avoiding material sticking and material deposit.

Multiple rotate-speed configurations

Multiple-rotate-speed gearing device can deal with different materials and conditions. The gearing configuration is only adjusted inside the reducer; the appearance and connecting part are universal, which makes the mixer’s application wider.

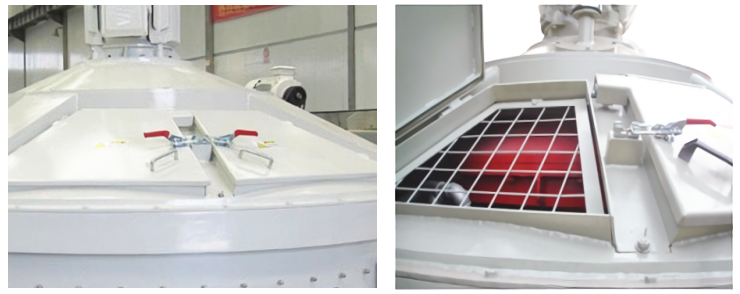

Improved mixer cover

Enlarged mixer cover port enables the reducer pulled out directly without detaching any feeding device; on the other hand, the maintenance space inside the mixing trough becomes bigger correspondingly. Real big maintenance door, not maintenance port any more, is more convenient for maintenance personnel to enter into the mixing tough to make maintenance and replace wearable parts. The innovated sealing structure of mixing cover effectively improves the dust-proofing effect.

Newly designed discharging port (optional)

The innovated integrated structure is equipped with imported screw oil cylinder, safer, more reliable, more beautiful, and occupying less space. Hydraulic pump station can meet the requirement of multiple discharging doors. The mixer is equipped with manual pump, which enables to open the discharging door manually in case of sudden power off.

Safer operation

The junction box is equipped with emergency stop switch, ensuring powering off immediately in case of emergency circumstances. Please do remember to take off the key during maintenance to avoid accidental starting up. The maintenance door is equipped with viewing port for observing the mixing condition; and the safety switch on the maintenance are of high reliability and sensitivity, which makes the repairing safer and more convenient.

Unique gearing system

New gearbox, is stronger, more durable and more compact, providing larger maintenance space; innovated shaft end sealing device improves reducer’s service life, and more lubricant pumps added reduces daily maintenance work.The series of JN planetary mixer are different from HZSseries (such as hzs25concrete batching plant,hzs35 concrete batching plant,hzs60 concrete batching plant)concrete mixer plant in shapes,production scale, but the the working principle is roughly the same.

SERVICE

1. Guarantee time

All of the life time of SMART machine, free for the first 12 months except the wrong operation.

2. Free Spare parts

SMART will prepare the one set spare parts and delivery them along with the machine.

SMART have the 12 workshops to produce every parts and we can produce spare parts to deliver them to you within 2 days.

3. Technical supporting

SMART Engineer will train you workers to make sure that they know every detail about the machine to make sure they know how to deal with the urgent situation and can repair some normal problem

4. Office

If we have more than 5 orders in one Area, we will set one office there to take care the after-sales service.

Video

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier