Video

1 / 2

everhard wear plate

thickness:

- 4~60mm

Options:

- 3+3*1200*2400mm

- 6+4*1200*2400mm

- 8+7*1200*2400mm

| Brand Name : | HP Plate, HP Welding |

|---|---|

| standard : | Aisi,Astm,Bs,Din,Gb,Jis |

Suzhou, Jiangsu, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

Product Description

1) Everhard wear plate is a high carbon alloy steel plate. This means AR is harder due to the addition of carbon and formable and weather resistant due to the addition of alloy.

2) The carbon added during the steel plate forming process significantly increases the toughness and hardness, but reduces the strength. Therefore, Composite Wear Plates are used in situations where wear and tear is the primary cause of failure. Abrasion Resistant Plate is not suitable for structural building applications such as bridges or supporting beams in buildings.

Common uses for Abrasion Resistant Plates include conveyors, buckets, dump liners, construction accessories, gratings, body armor and ballistic plates.

3)Wear Plates are usually manufactured in the rolled state. These types/grades of steel sheet products are developed for long service life in harsh conditions. Duplex Wear Resistant is suitable for a variety of applications in mining/quarrying, conveyors, material handling and construction, and earthmoving.

Quick View On Product

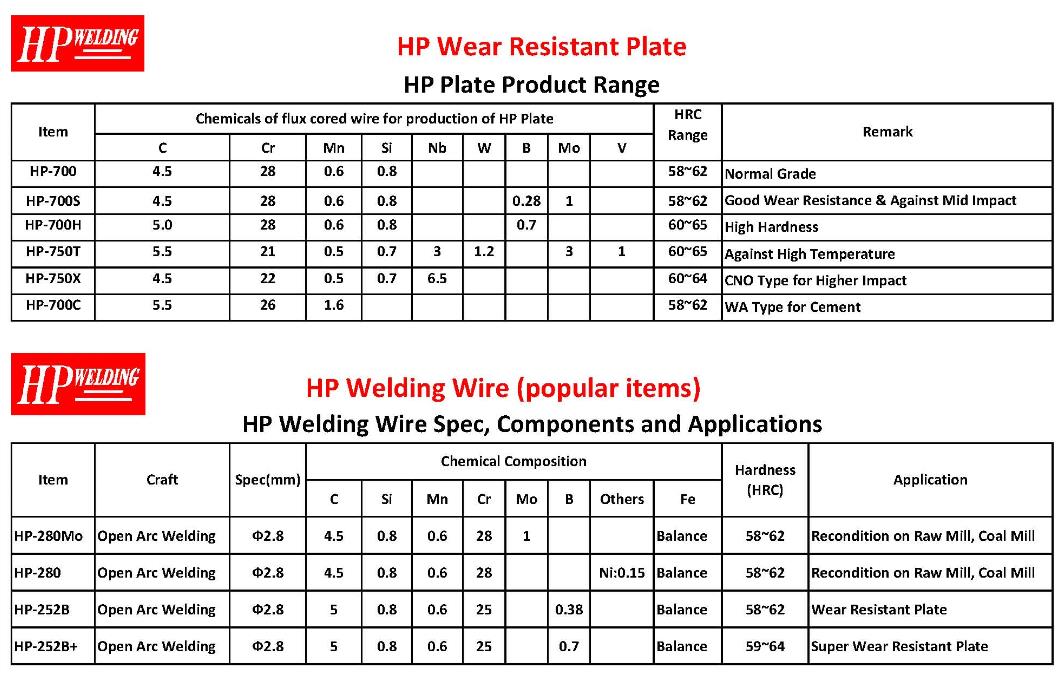

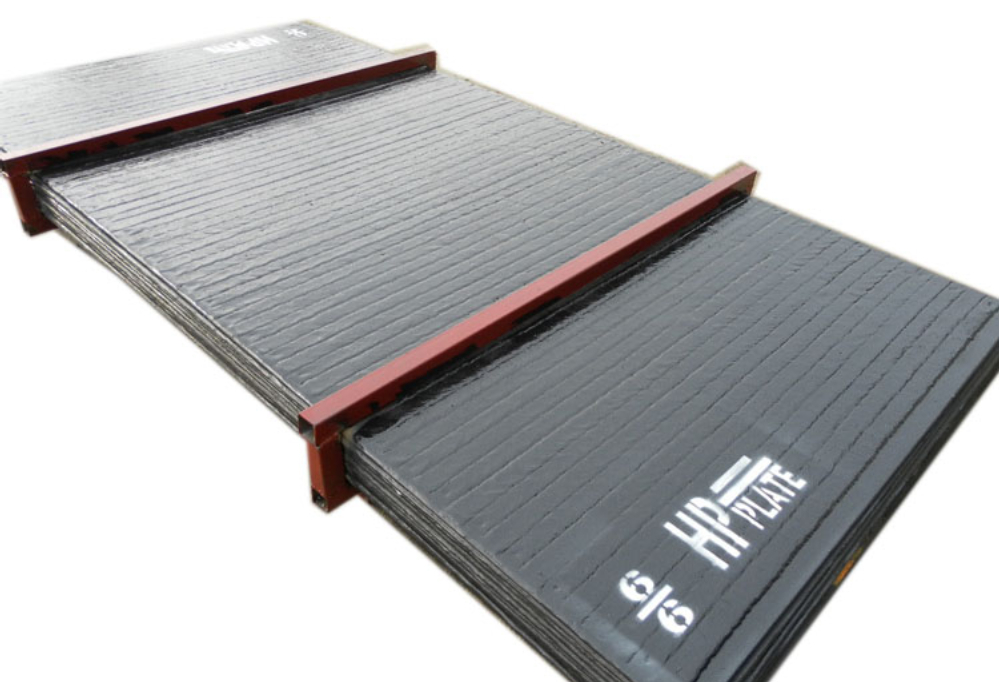

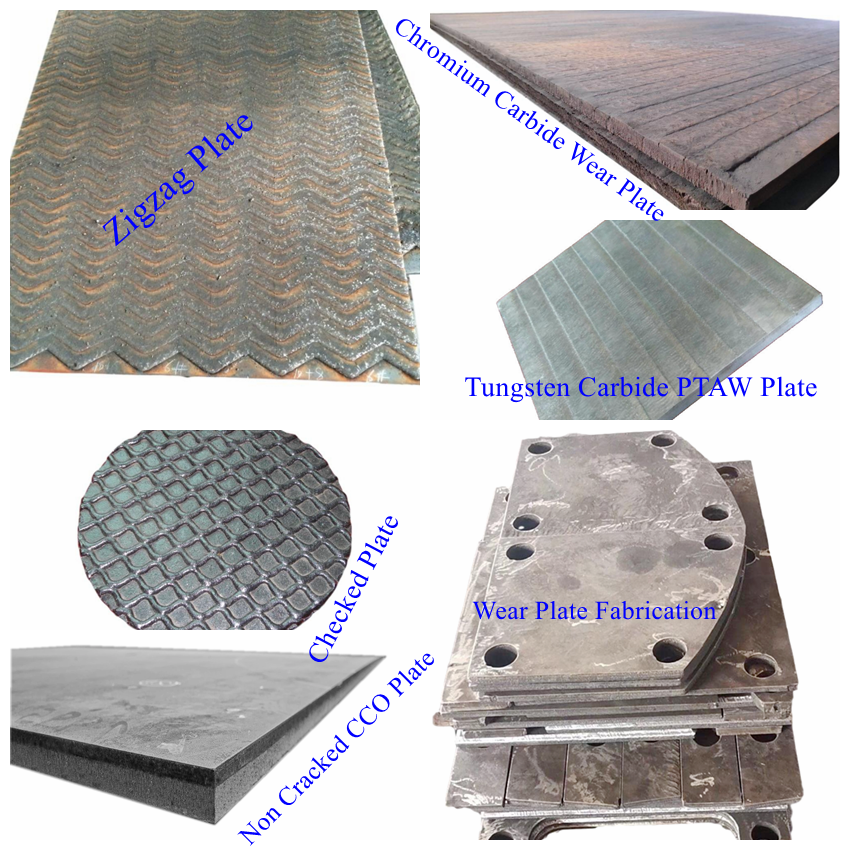

1. Product Name: HP Non Cracked Overlay Plate

2. Body Material: A36 Mild Steel + Chromium Carbide Overlay (Hardfacing)

3. Standard Size: 1200*2400mm; 1000*3000mm or Customised

5. Quality Standard: ASTM G65, AISI, ASTM, BS, DIN, GB, JIS

6. Applications: Cement Industry,

7. Certification: ISO9001, SGS, CTI, ROHS

Standard Specifications of

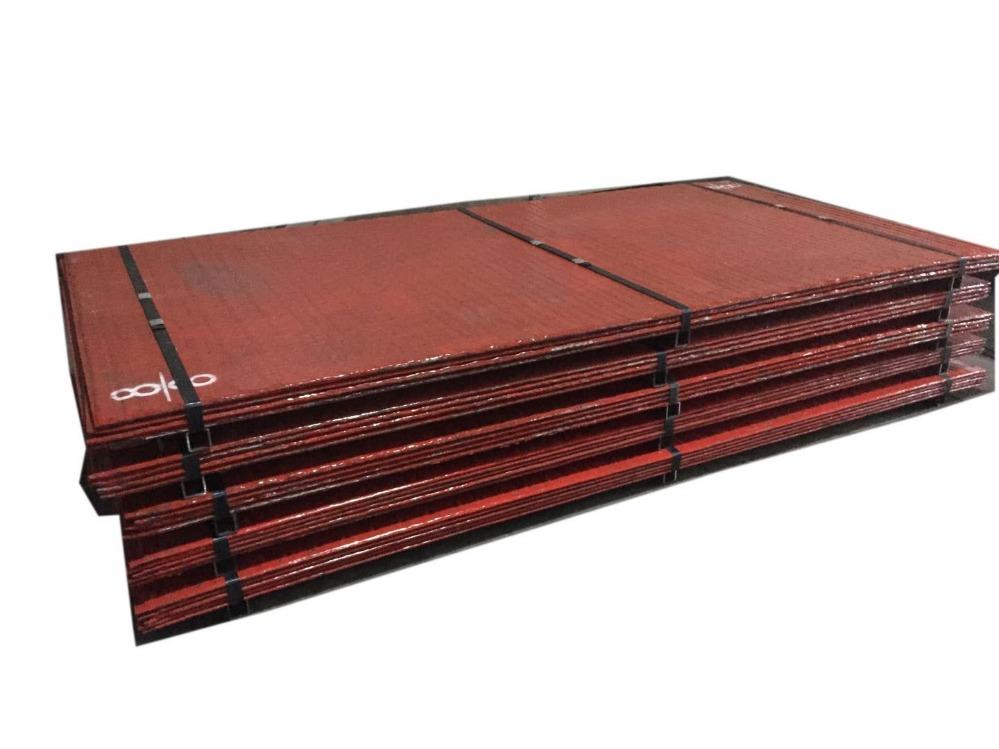

Packing & Delivery of Wear Plate

Packing Way: By Steel Tube, By Steel Belt, By Steel Pallet

Delivery Time: 20 days after order confirmation

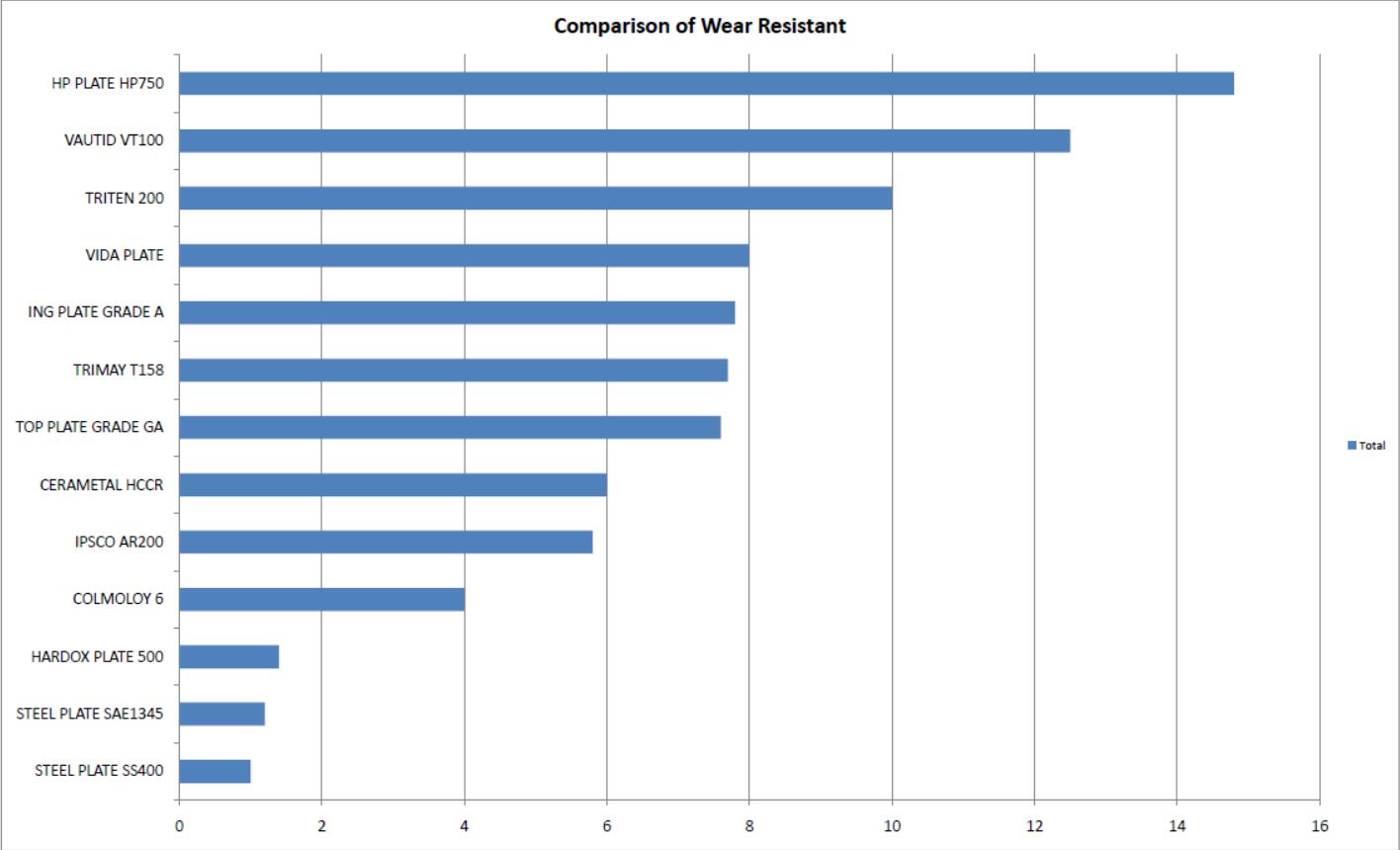

Anti-abrasion Comparison_HP Plate vs Other Plate

Company Information

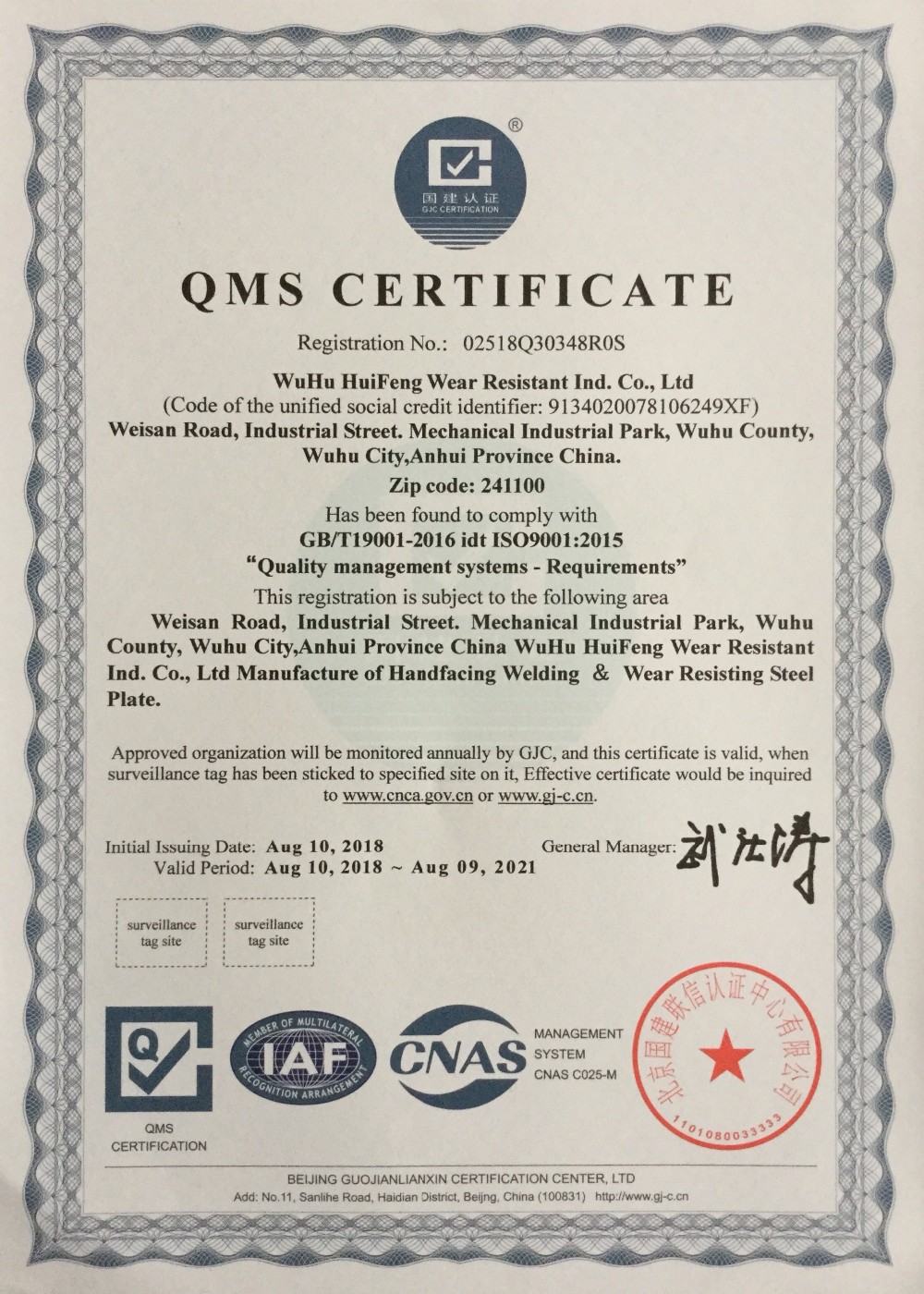

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert specializing in production and sales of wear resistant products.

HP Wear Products Range:

HP Wear Product Applications

Cement Plant, Mining Site, Steel Mill, Power Generation, Glass Industry,

Dredging, Surgar Industy, Quarry, Construction, etc...where need to be anti-abrasion.

HP Factory Laboratory

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Answer: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

1. Product Name: HP Chromium Carbide Overlay Wear Plate

2. Body Material: A36 Mild Steel + Chromi

Question: Can I cut or drill a hole in an HP

Video

Suzhou, Jiangsu, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier