Video

1 / 4

Electrical Ceramic DBC Substrate For Power Electronics

$1.00

≥1 Piece/Pieces

| Model No. : | Customized |

|---|---|

| Brand Name : | Jinghui Ceramic |

| place of origin : | China |

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

Electrical Ceramic DBC Substrate For Power Electronics

Jinghui Ceramic has well-equipped electronic ceramic production equipment and testing instruments. We use the tape casting method to produce ceramic substrates. Our leading product is alumina ceramic substrates. The size and thickness of the products can be customized according to customer requirements.

As chip integration continues to increase, circuit wiring widths become more compact, and power dissipation per unit area becomes larger and larger, inevitably causing an increase in heat generation and easily causing device failure. Direct Bonded Copper (DBC) ceramic substrate has become an important electronic packaging material due to its good thermal and electrical conductivity. Especially in power electronics, most of the ceramic substrates used are DBC ceramic substrates.

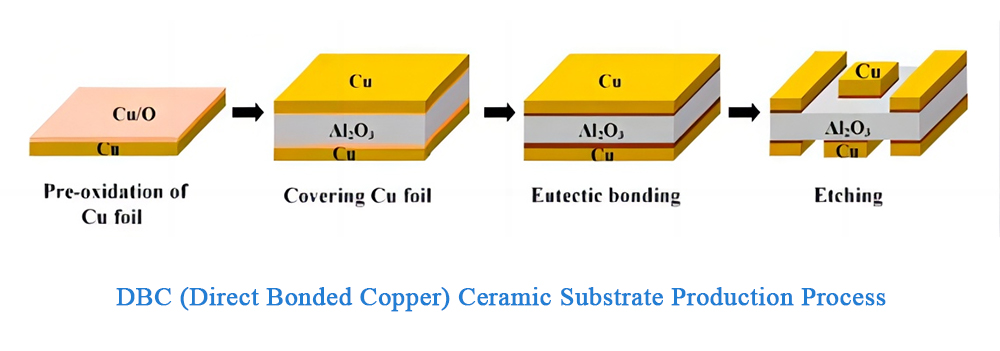

The Principle of DBC Process

DBC ceramic substrate is a composite substrate made by directly sintering copper foil to the ceramic surface at high temperature using a hot-melt bonding method. Direct Bonded Copper technology uses copper's oxygen-containing eutectic liquid to directly connect copper to ceramics.

The basic principle is to introduce an appropriate amount of oxygen between copper and ceramics before or during the coating process. At 1065-1083°C, copper and oxygen form a Cu-O eutectic liquid. DBC technology uses this eutectic liquid to chemically react with the ceramic substrate on the one hand to generate the CuAlO2 or CuAl2O4 phase, and on the other hand to infiltrate the copper foil to achieve the combination of the ceramic substrate and the copper plate. Then the film is exposed and developed according to the circuit design, and the circuit substrate is prepared by etching.

Advantages of DBC Ceramic Substrate

DBC ceramic substrate has the characteristics of high thermal conductivity, high electrical insulation, high mechanical strength and low expansion of ceramics, as well as the high electrical conductivity and excellent welding performance of oxygen-free copper, and can be etched with various patterns like PCB circuit boards.

Established in 2008, Jinghui Industry Ltd. View More

Video

Loudi, Hunan, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier