1 / 1

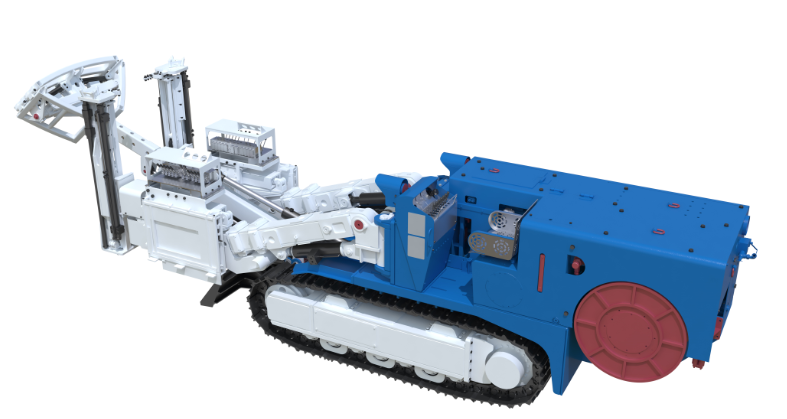

Double Boom Type Underground Mining Roof Bolter

| Brand Name : | NHG |

|---|

Shenyang, Liaoning, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Underground Mining Roof Bolter

All bolting jumbo rock reinforcement drill rigs convey safety. They fit to all ground conditions and offers flexibility in length and type of bolts as well as rapid bolt type conversion.

In addition to the comprehensive set of advanced features, the our rock reinforcement rigs also have automatic resin cartridge injection as a new option. Due to the usage and safe location of operators are no longer exposed to fumes. It provides cartridge sequence that can be either programmed and endlessly replicabled or set manually for each bolt. This feature ensures that the operator can easily adapt the grouting to what requires the ground conditions.

I. Technology Introduction

Bolt jumbo support is a fast, safe and economical way to support coal mine roadways. This support method is widely used in major coal producing countries at home and abroad. The bolt support rate in foreign advanced coal mining countries often exceeds 80%.

In modern high-yield and high-efficiency mines, continuous miners and subsequent supporting equipment have become important roadway excavation equipment. Continuous miners are mostly used in room or room and pillar mining, and double or multi-lane rapid excavation, with high output and fast lane formation speed. Since the goaf roadway needs timely support, the bolt drill carriage is particularly important among the supporting equipment of the continuous miner.

II. Performance Characteristics

ADVANTAGES OF BOLT JUMBO EQUIPMENT

· Our products and equipment were originally designed for the mine: they are robust, without unnecessary sophistications, easy to use and maintenance.

· In order to reconcile competitiveness and performance, these devices are based on a constructive system of customized as standard!

· A team of engineers, technicians, hydraulic engineers and fitters provide design, development, assembly and start-up equipment on site in the world.

Technical Parameter

| Location | Basic performance | unit | CMM2-12 | CMM2-15 | CMM2-16 | CMM2-18 | |

| Machine parameters | Dimensions | long | mm | 5900 | 5900 | 5900 | 5900 |

| width | mm | 1250 | 1250 | 1250 | 1250 | ||

| high | mm | 2190 | 2190 | 2190 | 2190 | ||

| Adapt to the roadway section | m² | 12 | 15 | 16 | 18 | ||

| Working range (width X height) | mm | 4600X2800 | 4500X3500 | 4600X3600 | 5000X3600 | ||

| Anchor rod and cable hole diameter | mm | Φ27-Φ32 | |||||

| Depth of anchor rod and anchor cable hole | m | 0-18 | |||||

| Drill rod specifications | mm | B19、B22 | |||||

| Total Weight | Kg | 10000 | 10800 | 10800 | 11000 | ||

| Slewing mechanism | Type characteristics | Hydraulic motor rotary | |||||

| Rated output torque | N.m | 300(17MPa) | |||||

| Rated speed | r/min | 550 | |||||

| Work flow | L/min | 80 | |||||

| Thruster | Propulsion method | Hydraulic cylinder + chain | |||||

| Advance itinerary | mm | 1600 | |||||

| Maximum feed force | KN | 15 | |||||

| Advancing speed | mm/min | 5000 | |||||

| Vertical flip angle | (°) | 270 | |||||

| Horizontal rotation angle | (°) | 180 | |||||

| Boom mechanism | Telescopic length | mm | 1190 | ||||

| Swing arm (inside and outside) | (°) | 20.4 | |||||

| Up/down | (°) | Oct-55 | |||||

| Propeller swing drive | Hydraulic screw swing cylinder | ||||||

| Walking mechanism | Walking speed | m/min | 0-15 | ||||

| Gradeability | (°) | ±15 | |||||

| Track width | mm | 350 | |||||

| Ground clearance | mm | 300 | |||||

| Ground pressure | MPa | 0.1 | |||||

| Electrical System | Total power | kw | 45 | ||||

| Supply voltage | V/AC | 660/1140 | |||||

| Rated speed | r/min | 1480 | |||||

Our Company

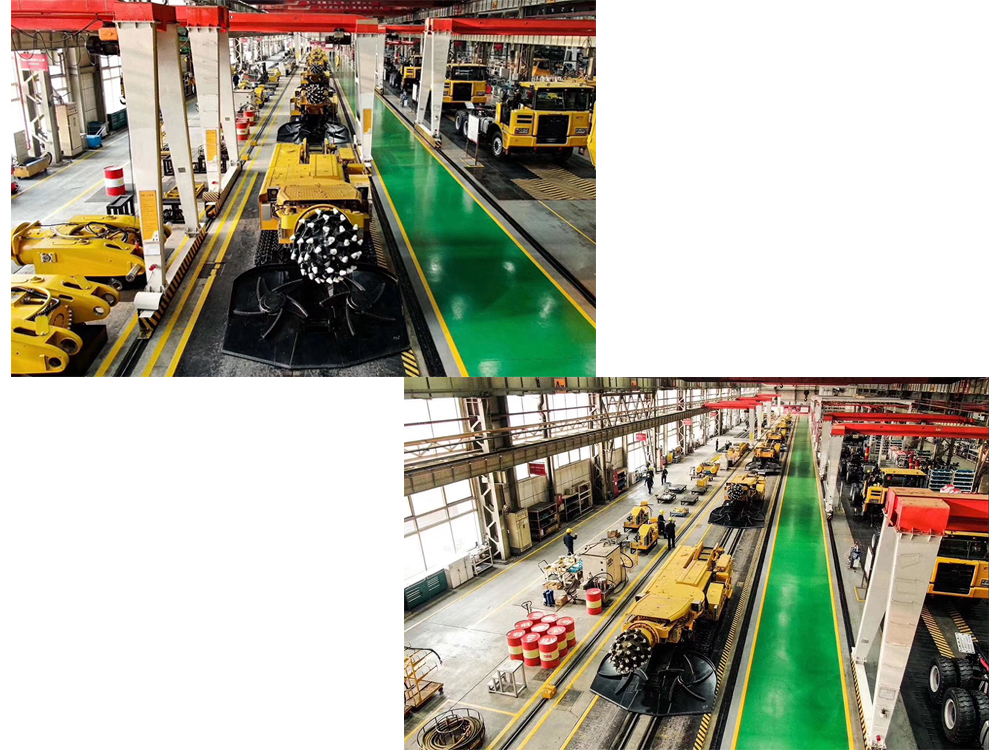

North Heavy Gryps Group (hereinafter referred to as NHG) was established in 1993. The company is headquartered in Shenyang Economic & Technological Development Zone which is honored by the State Department as “ Double Demonstration Zone” of national equipment manufacturing industry. NHG is specialized in the R&D, manufacturing and sales of mining and tunneling equipment and overseas mining and tunneling engineering services with more than 3,000 employees (including construction personnel) worldwide, 2,000 equipment and 300 construction projects providing services to different customers in more than 10 countries all over the world.

The company has established branches and offices in Southeast Asia (Laos), South Asia (India), Europe (Poland, Turkey), Russian (Novokuznetsk), South America (Venezuela), Africa (South Africa) and other countries. A regional operation network with equipment sales, service and parts supply and engineering construction has been established. The 24 × 365 service is implemented to meet the user's requirements to the greatest extent.

With the rapid development of NHG, adhering to the tenet of “QUATLITY WINS WORLD, TECHNOLOGY BUILDS NHG”, it is standing out as a pioneer in the industry and has become an international benchmark enterprise in China both for international sales of mining & tunneling machinery and also for international engineering construction services.

Shenyang, Liaoning, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier