Video

1 / 1

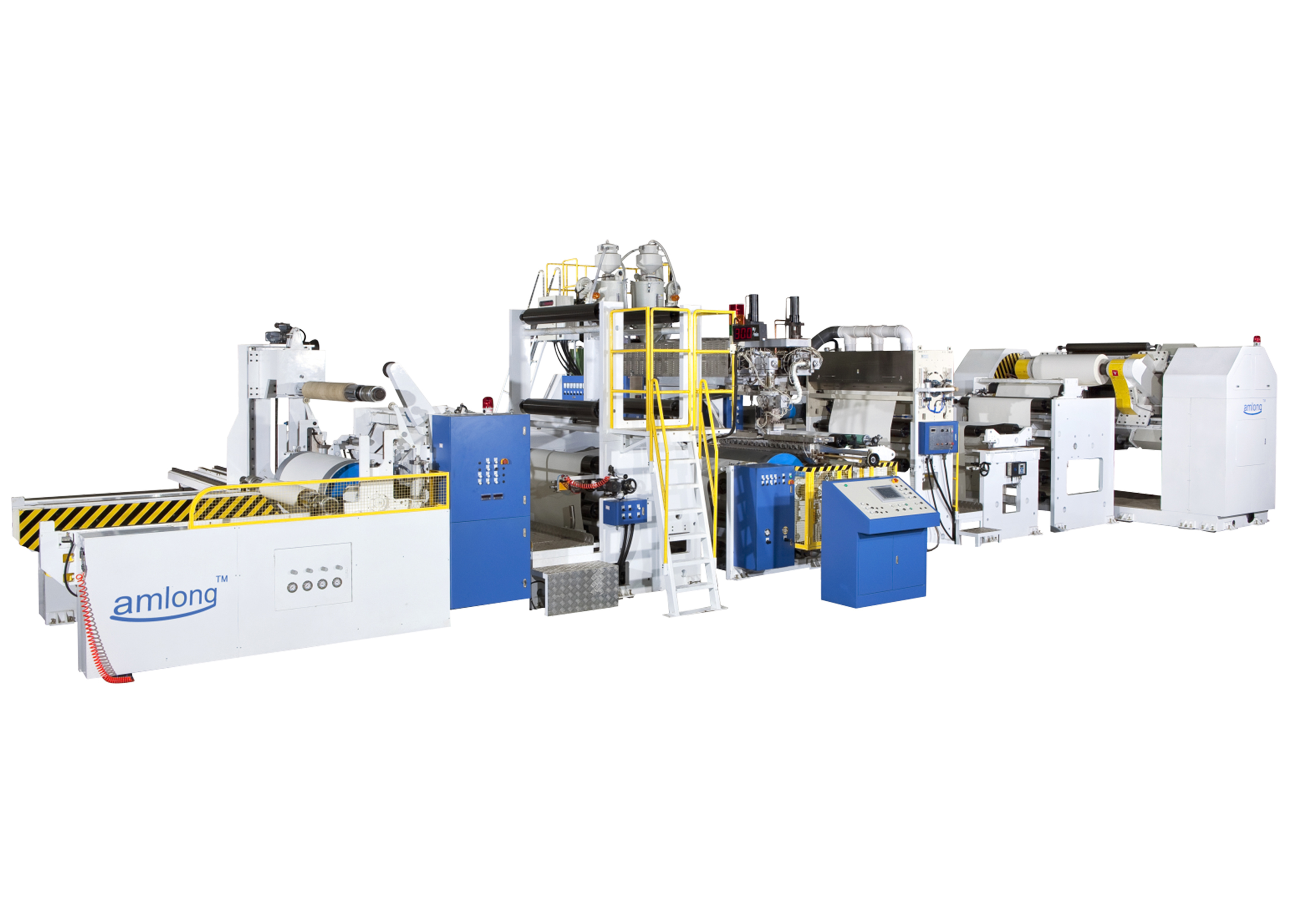

Disposable Paper Cup Extrusion Machine

Model:

- EXC1450/90/200/S

| Model No. : | Exc1450/ 90/ 200/s |

|---|---|

| Brand Name : | Huilong |

| application : | Sheet,Film |

Product description

The paper cup paper high-speed extrusion laminating machine is specially designed for disposable paper cup paper, cup paper, paper bowl paper and lunch box paper. , After extrusion, it is cast and compounded with the paper cup base paper to form a film on the surface of the paper. The paper is made into disposable paper cups after deep processing by cross-cutting machines, paper cup machines and other equipment.

The extrusion compounding process also has some shortcomings, such as large initial investment in equipment, large loss when heating or cooling or replacing resin, relatively complicated production and quality control, easy to produce high temperature odor and poor product flatness and other problems. In addition, the lamination strength of the extrusion lamination process is relatively low, especially when the extrusion lamination speed is fast. However, with the continuous development of plastic resin extrusion compounding equipment and technology, the shortcomings of extrusion compounding process have been gradually overcome. At the same time, the scope of basic products is further expanded, and its unique advantages are becoming more and more obvious.

Paper cup extrusion laminating machine is the summary of 25 years' experience in R & D of extrusion lamination coating machine of Huilong company, which is specially used for extrusion composite process of environmental friendly degradable materials such as PLA and PBS.

1.PLA paper extrusion laminating machine mechanical characteristics:

·Chaotic Mixing Low Energy Consumption Extruder·It is used for extrusion laminating process of environmental degradable materials such as PLA and PBS

2.Machine Specification(Product width):

1200mm(550-1100mm)

1450mm(700-1350mm)

1700mm(800-1600mm)

3.Speed:

200m/min

300m/min

4.Extruder:Manufactured using patented technology of Chaotic Mixing Low Energy Consumption Extruder

5.Extrusion output:

HL-65 extruder with max. extrusion output of 120kg/h;

HL-80 extruder with max. extrusion output of 200kg/h;

HL-90 extruder with max. extrusion output of 300kg/h;

HL-100 extruder with max. extrusion output of 400kg/h;

(When extruding LDPE)

6.Extruder motor power:

HL-80 extruder motor power: 45kw;

HL-90 extruder motor power:55kw ;

HL-100 extruder motor power: 75kw;

7.Resin extruded:LDPE/LLDPE/PP/EVA/EAA/EMA/EMAA, etc. coating grade resin

8.Extrusion thickness:6~40μm

9.Thickness uniformity of manual T-die:≤±5%

10.Diameter of unwind :ф1600mm

11.Tension of unwind:100~500N

12.Diameter of sandwich unwind :ф800mm andф1000mm

13.Tension of sandwich unwind:50~300N

14.Paper core dimension: Unwind: 3″and 6″; Rewind:6″

15.Diameter of chill roller:ф700mm orф800mm,double jacket with spiral runner design.

16.Tension Control:HMI operation; extrusion thickness is precisely automatic calculated by computer and linkage control of the whole machine

17.Inverter: Foreign brand AC digital vector control inverter

Video

Send your inquiry to this supplier