1 / 4

Digital products vacuum plating processing

Shenzhen, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- The Belt And Road

Product description

|

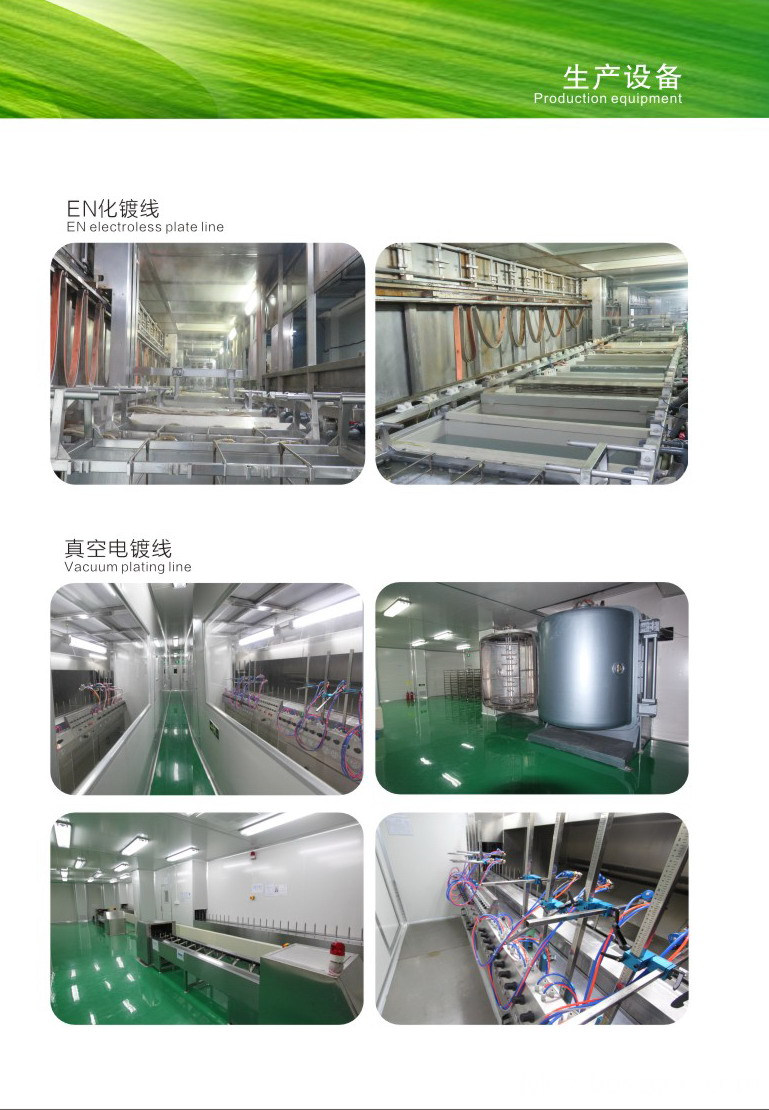

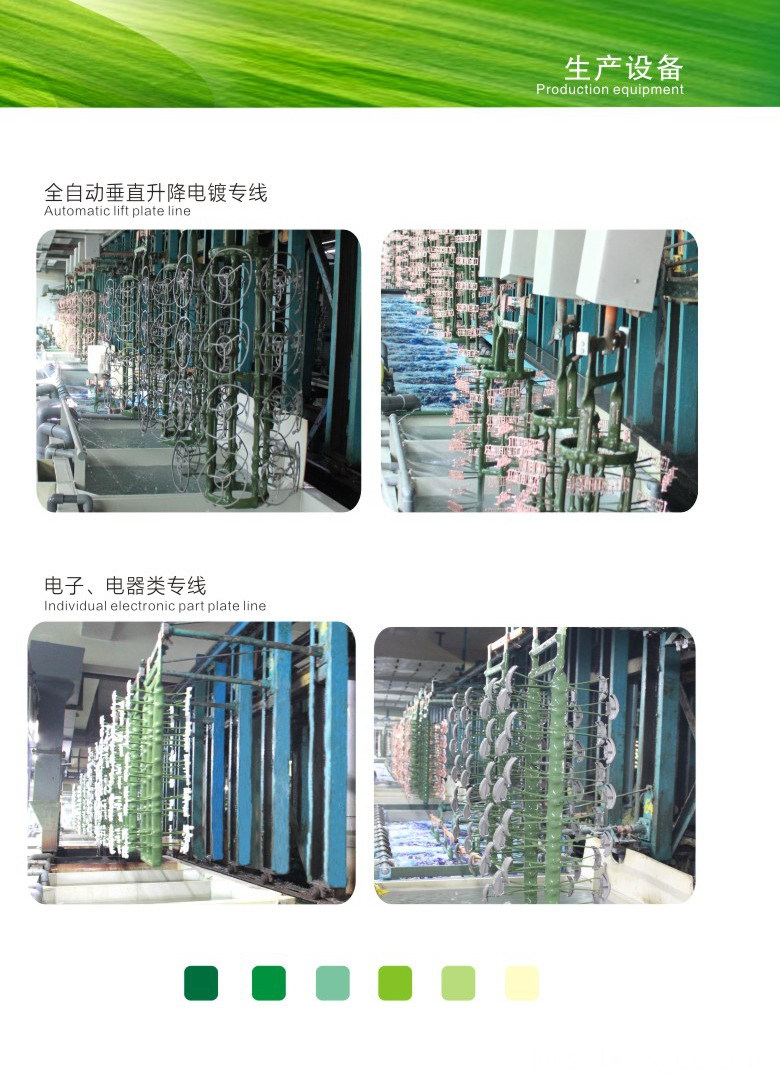

"Vacuum coating the first choice of Jinyuan Kang vacuum plating. 20 years experience in the production of vacuum coating, excellent quality, quality and cheap, a number of national patents. Products are widely used in digital products, vacuum plating processing. With the continuous improvement of people's living standards, All kinds of handicrafts, building materials, furniture, electronic products, automobiles, toys, lamps and other decorative surface of the increasingly high demand for non-metallic objects on the surface of metal or metal objects surface beauty, traditionally used plating method However, due to the traditional electroplating toxicity, waste pollution is particularly serious, people gradually strengthen the awareness of environmental protection today, its development has been subject to all aspects of the constraints.

Vacuum coating technology is a new technology developed in recent years. Its principle is the metal solid (such as aluminum, etc.) in a high vacuum state of heat and gas, and then molecular or atomic deposition in the substrate surface, so that the surface of the plating layer to form a thin layer of metal film. As the metal gas is evenly distributed in the coating machine cavity, so, usually, the surface of the metal plating film is very uniform.

Vacuum coating technology development and vacuum coating oil development success is inseparable. In a sense, we can even say that there is no vacuum coating of oil without vacuum coating. This is determined by the effect of the vacuum coating oil. In the process of vacuum coating, the coating oil plays a solid bond between the plating element and the metal film (that is, as the undercoat of the plating); after the vacuum coating, must be coated on the surface coating a layer of coating oil, then The oil also plays a protective metal film, dyeing and other effects (that is, as a plating of the surface coating). Most of the material in the coating before the coating surface must be coated with a thin layer of coating oil, thoroughly dry and then plated, otherwise, coated with metal film easily fall off, gently wipe with your hand Out. Vacuum coating process, the quality of coating depends very much on the quality of the undercoat.

Vacuum coating technology in the application of plastic products is the most extensive. Plastic products are easy to shape, low cost, light weight, non-corrosive and other characteristics, plastic products widely used, but because of its shortcomings constraints to expand the application, such as unsightly, easy aging, poor mechanical properties, heat resistance, high water absorption. Through the application of vacuum coating technology, the plastic surface of the metal, the organic materials and inorganic materials together, greatly improving its physical and chemical properties. Its advantages are mainly manifested in: First, improve the appearance, smooth surface, metallic luster color, greatly enhance the decoration; Second, to improve the surface hardness, the original plastic surface is soft and vulnerable than the metal, through the vacuum coating, hardness and wear resistance greatly increased; Third, to improve weather resistance, the general plastic in the outdoor aging soon, the main reason is caused by ultraviolet radiation, and aluminum, aluminum, the strongest reflection of ultraviolet light, therefore, greatly improved weather resistance; Fourth, reduce the water absorption, the more the number of coating, pinholes less, lower water absorption, the product is not easy to deformation, improve heat resistance; Five, so that the plastic surface conductive; Six, easy to clean, no dust.          |

Shenzhen, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- The Belt And Road

Send your inquiry to this supplier