Video

1 / 5

Cut To Length Line Machine

| Model No. : | HJ-400-5 |

|---|---|

| Brand Name : | YBBA |

| place of origin : | China |

Jinan, Shandong, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Product description

Application:

The cut to length line is an ideal machining equipment for producing transformer silicon steel sheets, and the most advanced equipment in China developed by us independently with reference to the cut to length lines of Germany Georg and Belgium Soenen.

Functional features:

1. Cut to length line can complete automatic production of various sheets for laminated, Full tapered seam cores.

2. Shearing power: imported electrical servo control technology is adopted, so the cut to length line is featured by high speed, low noise and long life.

3. Feeding power of the cut to length line: adopt high torque AC synchronous servo motor, so has characteristics such as rapid response, high positioning and accuracy, low noise, low braking thermal loss and long life.

4. Track positioning of the cut to length line: the centralized positioning is achieved by dragging the linear tracks of the ball screw with a servo motor. So the positioning is rapid, accurate and convenient and the track width can be memorized automatically.

Technical parameter

Type

Parameter

HJ-400-5

Coil material width tolerance

±0.1mm

Shearing burr

≤0.02mm

S° deviation

Single direction ≤0.02mm/2000mm

Width of sheet

40-440mm

Length of sheet

350-2000mm (short side)

Thickness of sheet

0.23-0.35mm

Accuracy in Length

±0.2mm/2000mm

Shearing burr

≤0.02mm

Lifetime of blade

Approx. Over 1.2 million cuts

Accuracy of shearing angle

±0.025°

Max feeding speed

0-240m/min

Cutting time per time

≤0.023s (electrical)

Punching mold burr

≤0.02mm

Lifetime of punching die

Approx. 0.3-0.5 million punches

Layers of step-lap

1,2,3,4,5,6,7,8

Max stacking thickness

450mm (containing material board)

Human-machine interface

Touch screen soft keyboard

Size of whole machine (L*W*H)

18m×8m×2.2m

Installation capacity

25kw

Flow chat

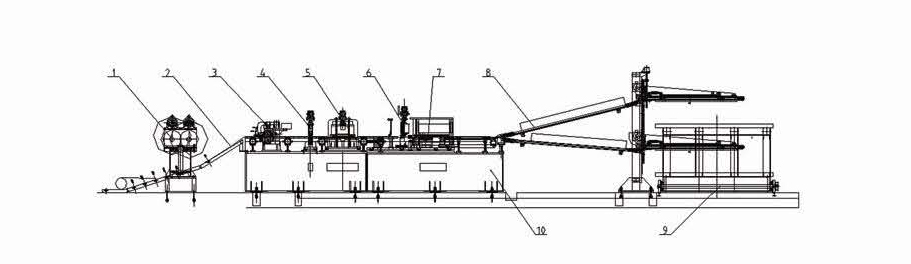

1. Twin head decoiler---2. Buffer mechanism---3. Feeding and measuring mechanism----4. O punch---5. V punch---6. Shearing unit---7. Divert mechanisn---8. Conveying mechanism---9. Magnetic adsorption stacking mechanism---10. Stacking trolley

Packing pictures

Video

Jinan, Shandong, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- Video

Send your inquiry to this supplier