1 / 4

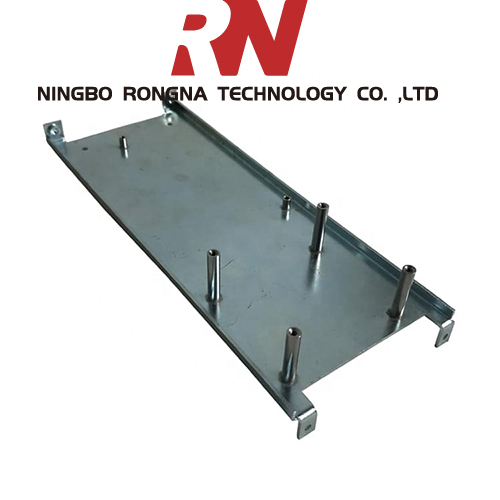

Custom sheet metal fabrication shop

Options:

- Custom

| place of origin : | China |

|---|

Ningbo, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Product description

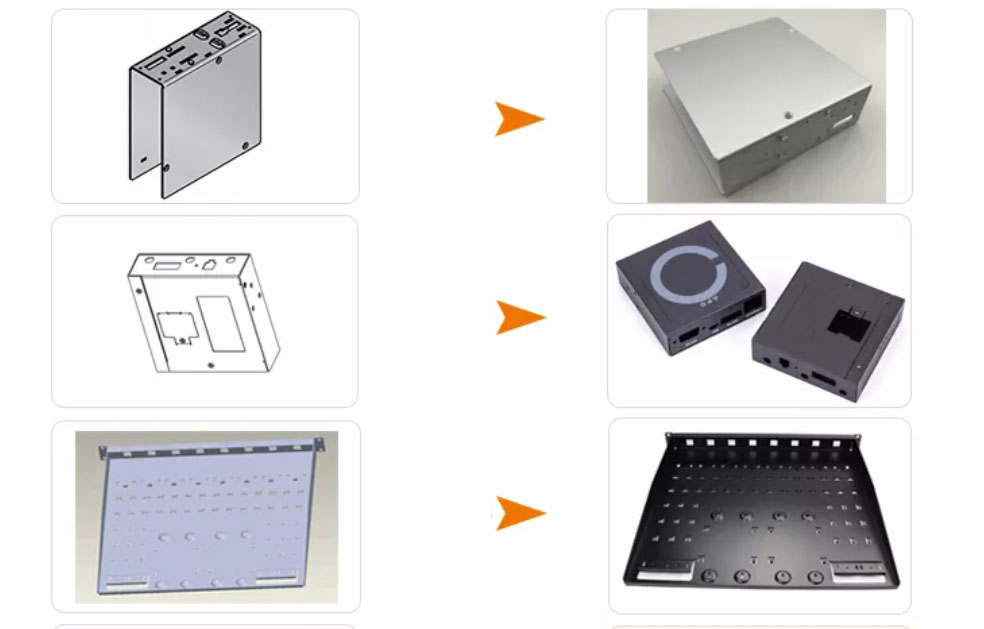

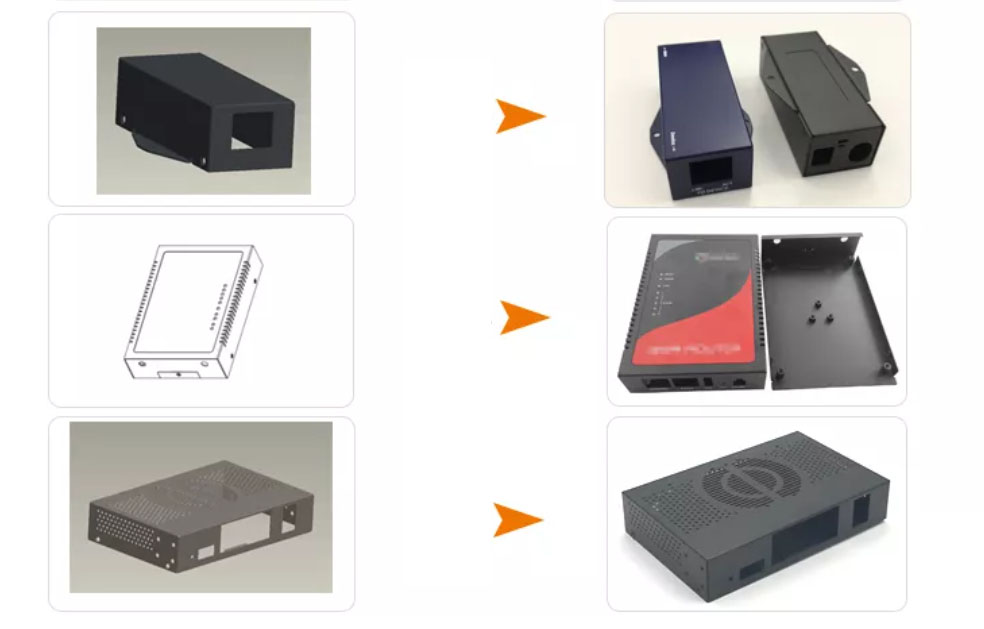

Modern sheet metal processes include: filament power winding, laser cutting, heavy duty machining, metal bonding, metal drawing, plasma cutting, precision welding, roll forming, sheet metal bending, die forging, water jet cutting, etc. Sheet Metal Fabrication Service Sheet Metal Fabrication Service Sheet Metal Fabrication Service Sheet Metal Fabrication Service Sheet Metal Fabrication Service Sheet Metal Fabrication Service Sheet Metal Fabrication Service.Custom Sheet Metal Fabrication Service. Small quantity Sheet Metal Fabrication Service.Custom sheet metal fabrication shop.rapid prototype. cnc machining.

There are many sheet metal materials suitable for stamping processing. Sheet metal materials widely used in the electronic and electrical industry include:

1. Ordinary cold rolled sheet SPCC

SPCC refers to the continuous rolling of steel ingots into steel coils or sheets of required thickness through a cold rolling mill. SPCC surface does not have any protection, it is easy to be oxidized when exposed to the air, especially in a humid environment, the oxidation speed is accelerated, dark red rust appears, and the surface should be painted, electroplated or otherwise protected when in use.

2. Galvanized steel SECC

The substrate of SECC is ordinary cold-rolled steel coil, which becomes an electro-galvanized product after degreasing, pickling, electroplating and various post-treatment processes in a continuous electro-galvanizing production line. SECC not only has the mechanical properties and similar processability of ordinary cold-rolled steel sheets, but also has superior corrosion resistance and decorative appearance. It has great competition and substitution in the market of electronic products, home appliances and furniture. For example, the commonly used computer case is SECC.

3. Hot dip galvanized steel sheet SGCC

Hot-dip galvanized steel coil refers to the semi-finished product after hot-rolled pickling or cold-rolling, after cleaning, annealing, and immersing in a molten zinc bath with a temperature of about 460 ° C, so that the steel sheet is plated with a zinc layer, and then quenched and tempered. Flattened and chemically treated. SGCC material is harder than SECC material, has poor ductility (avoid deep drawing design), thicker zinc layer and poor weldability.

4. Stainless steel SUS301

The content of Cr (chromium) is lower than that of SUS304, and the corrosion resistance is poor, but it can obtain good tensile force and hardness after cold working, and has good elasticity. It is mostly used for shrapnel springs and anti-EMI.

5. Stainless steel SUS304

One of the most widely used stainless steels, because it contains Ni (nickel), it is richer in corrosion resistance and heat resistance than steel containing Cr (chromium), has very good mechanical properties, has no heat treatment hardening phenomenon, and has no elasticity.

Rongna: IGES (.igs) /STEP (.stp) /Parasolid (.x_t) / .stl files.

Rongna: Sure. We never divulge customers' information to anyone else.

Rongna : 1 pcs , we provide prototype to mass production service

Rongna: Exress UPS/FedEx . shipping by sea

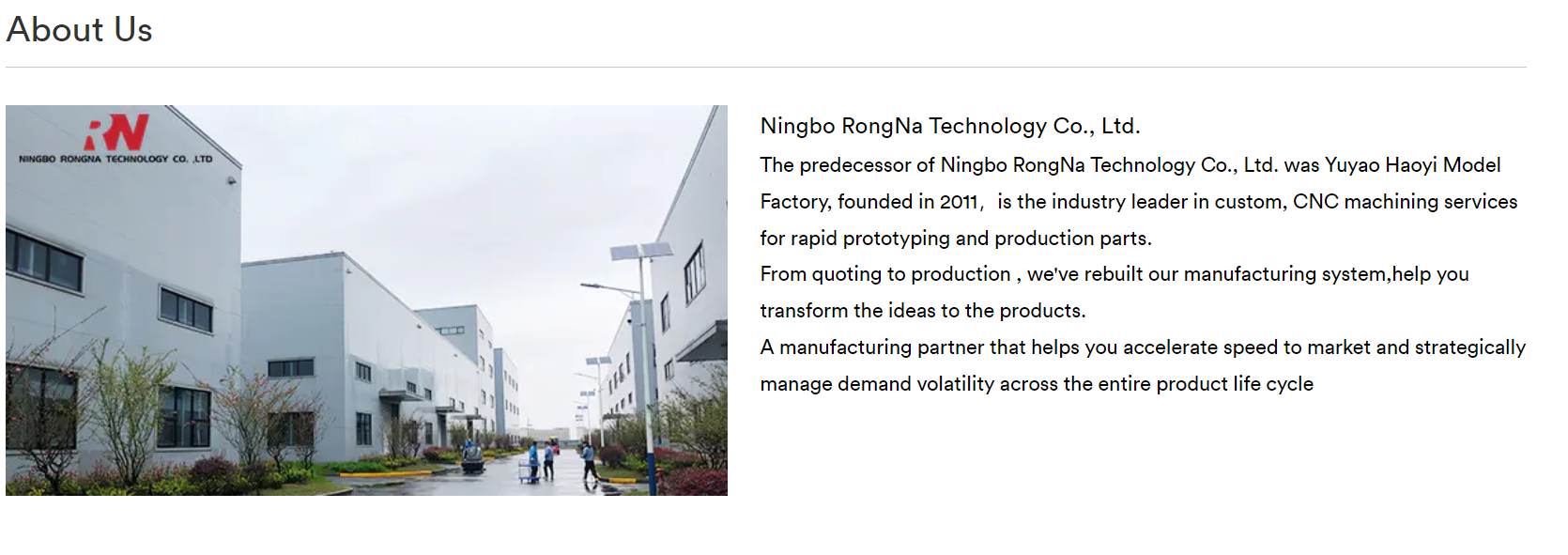

we help client Develop New Products, form Sample to mass Production.

Ningbo, Zhejiang, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier