1 / 4

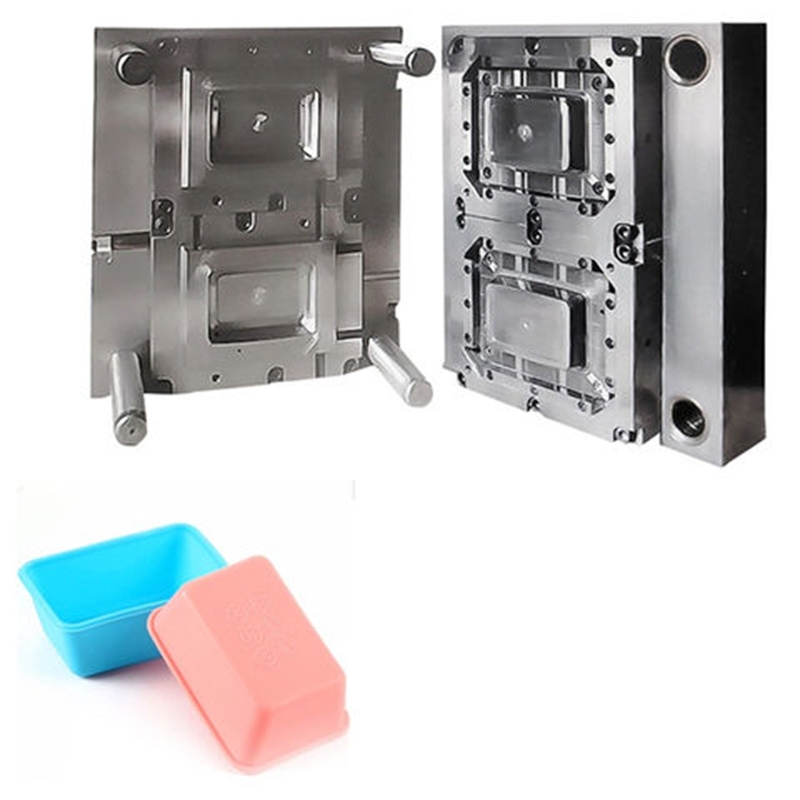

custom molded Silicone rubber parts

| Brand Name : | BHC |

|---|---|

| Surface finished : | Texture, Polish,Plating |

Dongguan, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Gold Supplier

Product description

We produce Customized Silicone rubber product, Home Appliance Silicone, Medical Silicone, Sealing Ring Silicone, Electronic And Industrial Rubber.

Usage: Agricultural, Industrial, Medical, Vehicle, Electronic, Household

Material: Silicone RubberProperty: FDA

Shape: Customized

Hardness: 30-90 Shore a

Tensile Strength: >=17MPa

Elongation at Break: >=300%

Working Temperature: -40~230 Celsius Degree

File Format: Auto CAD, Pdf, JPG,STP

What are the purpose of opening the sample mold for silicone products?

1. The number of cavities opened by the sample mold is small, the use of the materials is small, and the processing time is short, so the cost is relatively small and the efficiency is high.

2. Opening the sample mold can also bring some other benefits. For example, even if the product structure is not confirmed for the first time, it is convenient to modify the mold. After modification, it can be proofed and confirmed immediately, which shortens the time.

3. Because of the low cost, opening the sample mold first can reduce the risk. If you directly open the large mold and can't confirm the sample for the first time, many quality problems will be brought when using the modified mold to produce products. In this case, the more the mold is modified, the worse it is, and the more it is modified, the more it is not conducive to production. Therefore, opening a sample mold can achieve the purpose of first confirming the product. If it is confirmed that there is no problem, open the large mold at one time. In this way, the products produced rarely have quality problems.

Dongguan, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Gold Supplier

Send your inquiry to this supplier