1 / 4

cross coupling cable protectors

| Brand Name : | junlong |

|---|---|

| Where to provide local services (in which countries are there overseas service outlets) : | Japan,Australia,Uae,Turkey,United States,United Kingdom,Saudi Arabia,Indonesia,Mexico,Russia,Spain,Italy |

Weifang, Shandong, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Organization

- Service

- OEM service

- Gold Supplier

- Platform Certification

Product description

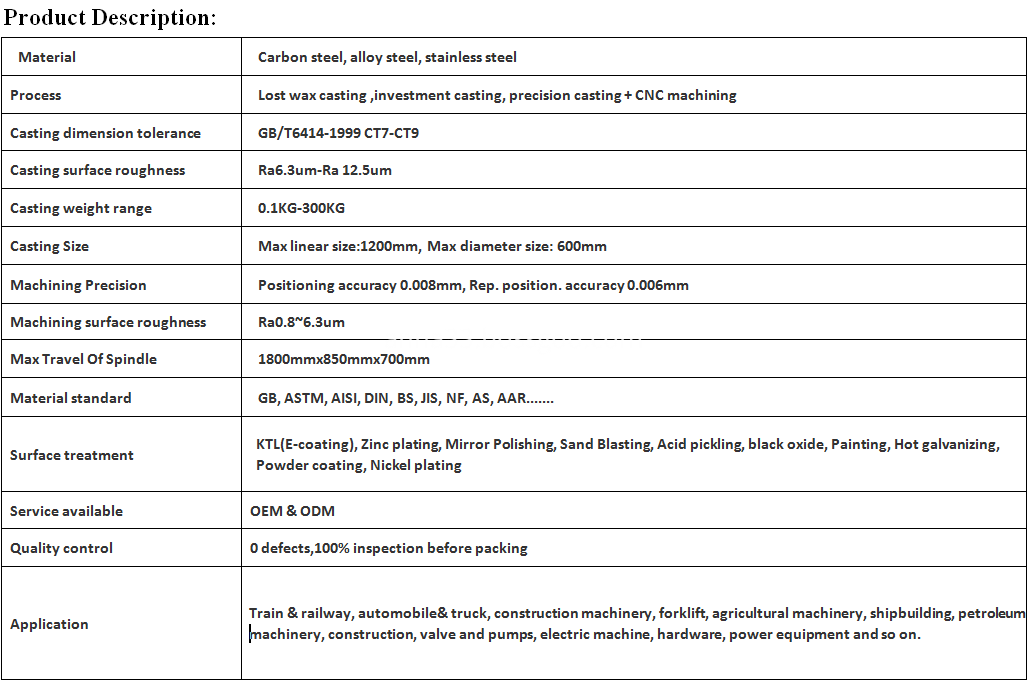

The introduction of the cast steel cross coupling protector to the oil and gas industry in the mid 1980`s served to revolutionise the protection of downhole cables used to power electric submersible pumps (ESP`s), safety valves and other downhole equipment. Historically, damage to downhole cables due to crushing between the production tubing couplings and the casing internal diameter cost the industry millions of pounds in unscheduled workovers and recompletions. The North Sea is one of the most hostile of environments, but today, cable damage is virtually unheard of. This is directly attributable to the introduction of cast steel cross coupling protectors. During the past ten years, the cast steel cross coupling cable protector has been introduced throughout the world`s oil and gas producing regions and from its humble beginnings in the North Sea is now protecting downhole cables from mechanical damage in thousands of oil and gas wells on land and sea throughout the world.

Wei fang jun long Ltd offers a full range of all metal cross coupling cable protectors with robust cast steel bodies to the oil and gas industry. This new range of cable protectors has been designed with total protection in mind and incorporates some new design features which place it ahead of the competition with regard to cable protection.

Features:

This product has a lot of specifications and is suitable for use. Its weight is about 4kg-12kg. Our company now has 6 specifications

Investment casting is widely used in petroleum machinery, such as oil drilling and mining machinery equipment, petroleum machinery parts, tools, wellhead devices, and other equipment. Most of them use high chromium steel castings, Our company can develop, design, mass production, OEM and odm for petroleum machinery casting.

In addition, such as mining machinery castings, train parts castings, auto parts castings, can be designed and processed

Wei fang Jun long precision casting co., LTD., the main products are precision casting of carbon steel, low carbon steel, medium carbon steel castings, high carbon steel, alloy steel precision casting, high manganese steel, high chromium steel, high nickel steel, a variety of materials such as precision casting products .The parts are mainly used in precision casting of auto parts, forklift parts castings, precision casing of ship parts, precision casting of train parts, mechanical engineering, petroleum machinery, mining machinery .Our products has been exported to more than 20 countries and regions in the world. Our company has cooperated with our customers with the business philosophy of integrity, pragmatism, professionalism and innovation, and won the unanimous praise of our customers

The company covers an area of 30,000 square meters, with more than 200 employees, 10 r&d personnel and 12 quality control personnel. There are three production lines, two composite process (i.e. silica sol + water glass), and one silica sol process. The annual output reaches 8000 tons, the enterprise has passed iso9001:2005 quality management system certification, and passed the national environmental protection department approval, has the formal environmental assessment certificate, is a household name of the green casting enterprise

All the assembly lines in the workshop are made by our general manager according to practical experience. The product quality can be guaranteed while greatly improving the work efficiency and reducing the workload for the workers. By the end of 2015, all the workshops of our company have been automated production .For example, automatic wax injection machine, automatic silicon sol process robot, automatic silicon sol process wind main line, automatic water glass process assembly line and curing pool, automatic pouring. Because they are all automated production, the quality of the shell is guaranteed in the early stage,Precision casting products with weight from 0.1KG to 500KG can be completed .Products with wall thickness as low as 3mm. Products with complex shapes.The defects of porosity, sand hole, slag inclusion, cold insulation, shrinkage and other casting defects are effectively avoided

Are main products of our company adopted complex process (silica sol + water glass), adopt the low temperature wax, four shell layer using silica sol process, three layer using water glass process, composite process to produce a product that no matter from the surface finish, and internal quality and silicon sol process almost the same, the price is cheaper than silicon sol process a lot, and water glass price though it's cheap, but the product is very rough, and composite technology products of good quality and low prices, the most suitable for large batch of products, can guarantee the quality of customer requirements, and can guarantee a reasonable profit space, so, Our foreign customers have been cooperating with us for 8 years, and we have cooperated very well.

Inspection: our company has special physical and chemical laboratory, with perfect inspection equipment (spectrometer, three coordinate measuring machine, metallographic analyzer, impact test machine, tensile testing machine, hardness tester, magnetic particle inspection machine, ultrasonic testing, etc.), can satisfy the customer different product requirements, and issue a corresponding test report

Processing: we have two horizontal machining center, CNC machining center, bench drill, vertical drilling machine, rocker arm drilling machine, milling machine, grinder, planer, CNC lathes and other all-round machining equipment

Weifang, Shandong, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Organization

- Service

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier