1 / 5

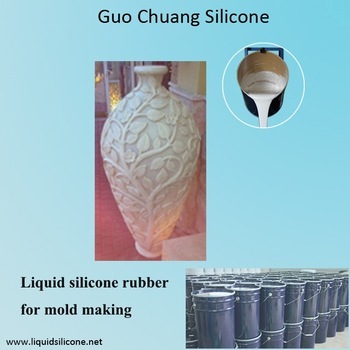

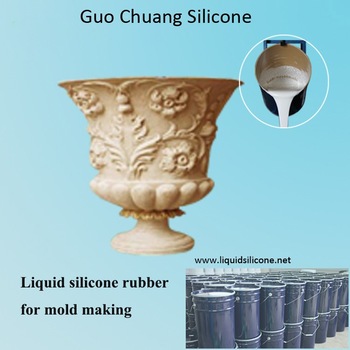

condensation rtv silicone liquid molds for pottery making

| Model No. : | C828 |

|---|---|

| Brand Name : | GC silicone |

| Raw Material : | Synthetic Rubber |

Product description

1.Description of condensation rtv silicone liquid molds for pottery making

It is a kind of Two-parts silicone, part A is flowable liquid silicon, part B is curing agent/ catalyst ,which gets cured at room temperature 25℃ within 3-6 hours or heating curing .This product is perfect for cement , concrete stone, GRC and GFRC products` mold making,such as the flower pot , fountain,Polyurethane Wood Imitation,Reinforced Plastic,Garden Decorations ,fiberglass product and other decoration industries.

2.Characteristics of condensation rtv silicone liquid molds for pottery making

1.High duplication times and no deformation

2. Excellent tear strength and tensile strength.

3.Good fluidity and good operability and good for both pouring method and brushing method.

4.Excellent flexibility and it`s easy to demould.

5.It gets cured at room temperature 25℃ within 3-6 hours.

6.Suitable hardness from 30 to 40 shore A

3.Application of condensation rtv silicone liquid molds for pottery making

pottery molding

Concrete/GRC Casting molding

artificial stone /Rock molding

Polyester/Resin Crafts Molding

Furniture Molding

Candles Molding

Soaps Molding

Tire Molding

Rapid Prototyping Urethane casting

Detailed reproduction of figurines, art objects and similar items

FAQ:

1. Why will the silicone mold be reused only for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which can destroy the molecular weight of silicone rubber and reduce the tension and tear strength.

b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs or the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.)

2. Why does the silicone mold appear to dry outside but wet inside?

Because molding silicone rubber is a kind of condensation silicone rubber, which get solidified after absorbing moisture from the air. In order to provide a significant shelf-life for the silicon rubber, we will dry out the water in the silicon rubber.

Solution: Add 0.1% water into the silicon rubber and Stir over a low speed briefly when you use it.

3. Why is the silicon mold oily?

The molding silicone rubber itself doesn`t contain any oil, so it won`t be oily. If the mold is oily, it may be because you add the compound silicone oil( the compound of silicon oil and white oil). The white oil is not silicon oil but a kind of petrochemicals.

Send your inquiry to this supplier