1 / 4

Coil Straightener-Feeder 3 In 1

| Model No. : | MFL4-H |

|---|---|

| Brand Name : | Mayflay |

| Applications : | Pressing Line/Metal Stamping Line/Forming Line |

Huizhou, Guangdong, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- Online Expo

Product description

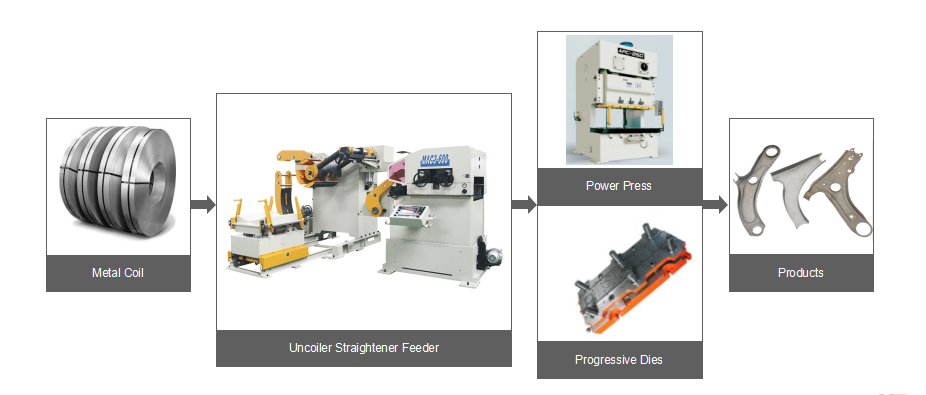

COIL STRAIGHTENER FEEDER 3 IN 1

Coil Straightener-Feeder 3 In 1 space saving design combines a feeder/straightener with a powered decoiler. The slack loop is developed below the spindle, reducing floor space significantly compared to conventional slack loops. We offer numerous optional features to suit specific application requirements, including peelers, hold down arms, or pilot releases. This system is designed for 0.6-6.0mm thickness steels with higher tensile strength materials needing to be run in a compact setting. By developing the loop below the spindle and incorporating a feeder with a straightener, significant floor space is conserved. Pilot release for both feed and straightener rolls is available, making this an ideal design for progressive die applications.

Thick steels with higher tensile strength require special care in the coil handling process. Safety, longevity and ergonomics become more important than feeding dynamics. Additionally, the machinery framework must withstand especially high torque and clock-spring forces.

Coil Straightener-Feeder 3 In 1 range comprehends standard straighteners for eliminating the coil bow as well as levellers for higher straightening requirement and precision straighteners with convex straightening rolls for highest straightening quality requirement. The maximum available standard working width, depending on type of straighener, is about 1800 mm.

The Compact Press Feeding Line realizes the combination of unwinding, straightening and feeding for heavy materials in a most efficient fashion.

SPECIFICATION

| Coil Straightener-Feeder 3 In 1 | |||||||

| Model:MFL4-H | |||||||

| Specifications | |||||||

| Model | MFL4-600H | MFL4-800H | MFL4-1100H | MFL4-1300H | MFL4-1400H | MFL4-1600H | MFL4-1800H |

| Material Width(mm) | 70-600 | 70-800 | 70-1100 | 70-1300 | 70-1400 | 70-1600 | 70-1800 |

| Material Thickness(mm) | 0.6-6.0 | 0.6-6.0 | 0.6-6.0 | ||||

| Max.Coil Weight(kg) | 5000 | 5000 | 7000 | 10000 | 10000 | 10000 | 10000 |

| Max.Coil O.D.(mm) | 1400 | 1400 | 1400 | ||||

| Coil l.D.(mm) | 508 | 508 | 508 | ||||

| Feed Length(mm) | ~500* | ~500* | ~500* | ||||

| Max.Line Speed(m/min) | 16-24 | 16-24 | 16-24 | ||||

| Straightener Roll (pcs) | upper6/lower5 | upper6/lower5 | upper6/lower5 | ||||

| Feed Roll (pcs) | 1 | 2 | 2 | ||||

| Main Motor | AC15 | AC15 | AC15.0 | AC22.0 | AC22.0 | AC22.0 | AC22.0 |

| Mandrel Expansion | Hydraulic | Hydraulic | Hydraulic | ||||

| Reel Motor(kw) | 2.2 | 2.2 | 3.7 | 7.5 | 7.5 | 7.5 | 7.5 |

| Power(V) | 3phase 220V/380V/50HZ | ||||||

| Operating Air(Mpa) | 0.49 | ||||||

Remarks:

1)The above figures are the material having yield strength σs=600N/mm².

2)Specifications are subject to change for improvement without notice.

PICTURES

The Main Detailed Parts of Coil Straightener-Feeder 3 In 1 for high tension material as below:

1. Coil Car---Hydraulic power, wear-resisting surface

1. Coil Car---Hydraulic power, wear-resisting surface2. Decoiler Mandrel ---Hydraulic Expansion, Delta Inverter

3. Pressing Arm---Coil well-knit, no disperse

4. Limiting Arm--- Locating coil, avoid coil shuffling

5. Support Arm---Auxiliary support coil

6. Coil Inlet---With supporting swing arm

7. Control Cabinet---Weinview Touchscreen

8. Straightening Part---GCr15 steel straightener rolls

9. Handwheel --- Straightening value adjustment

10. Shearing Unit---Hydraulic shear (Optional)

11. Lubrication Unit---Automatic control, 20L (Optional)

12. Outlet Bracket --- Adjustable length

APPLICATION

Automobile stamping, appliances manufacturing, computer and electronic componets, hardware and metal parts etc industry.

Automotive Parts: Bracket, Damper, Barke Pad, Tie Bar, Electric Accessory, Shell Parts Of Printers, Computer Frame,Slide Rail of Car Seat, Splash Shield of car body and etc

Coil Straightener-Feeder 3 In 1 is working in our customer's factory.

Coil Straightener-Feeder 3 In 1 is for making the bracket coil sheet feed line.

This machine is working in one of our customer's factory, they produce U type parts with Coil Straightener-Feeder 3 In 1.

With the Yaskawa Servo Systems and Mitsubishi PLC control, the feeding line can reach ±0.15mm feeding accuray.

Huizhou, Guangdong, China

- Manufacturer

- Service

- OEM service

- Platform Certification

- Online Expo

Send your inquiry to this supplier