1 / 4

Coarse Grinding Mill, Fine Crusher for Chemical Machinery

Power (Watts):

- 55KW

- 75KW

- 110 KW

Model:

- 800x400

- 800x600

- 800x800

| Model No. : | 800x800 |

|---|---|

| Brand Name : | ASCEND |

| Applicable industry : | Construction Works,Energy &Amp; Mining,Other |

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Product description

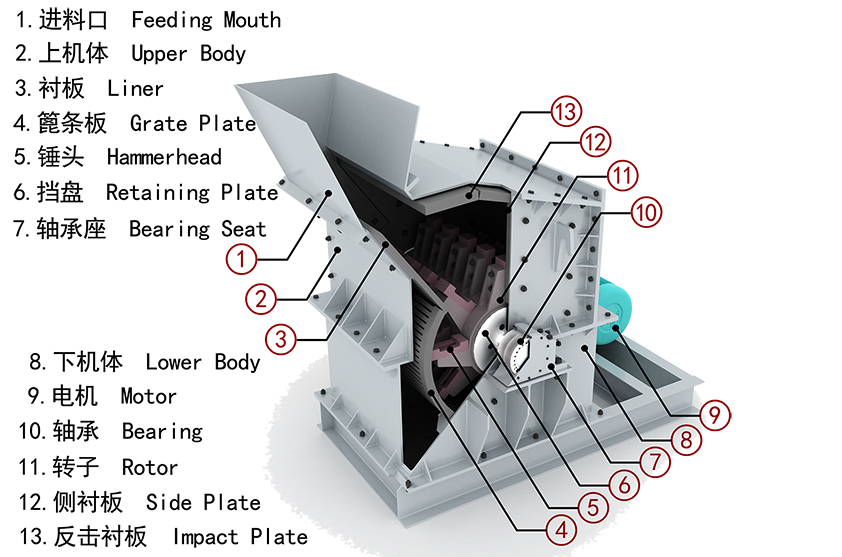

Sand making high efficiency fine crusher machine

High-efficiency fine crusher, also known as fine crusher, is especially suitable for making fine and medium crushed gravel, refractories, cement, quartz sand, steel sand and other hard and brittle materials. It is an efficient and energy-saving sand making equipment. Compared with the traditional fine crusher, it is a more advanced, effective, reliable and practical fine crusher equipment, and it is also the best-selling equipment.

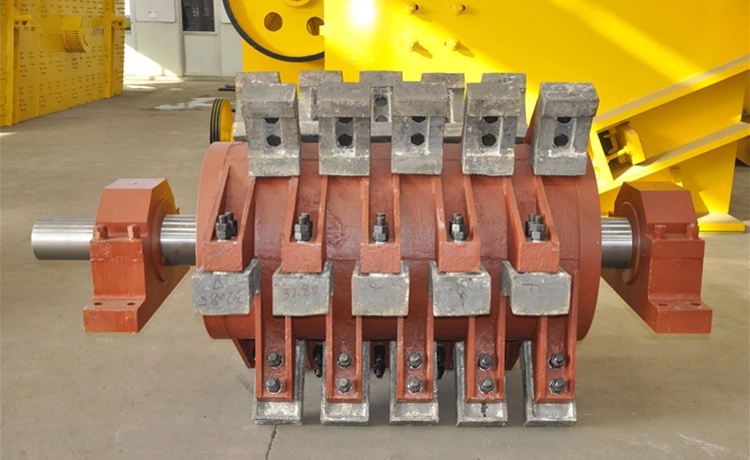

Fine crusher working principle

When the fine crusher is working, the materials enter the crushing cavity from the feeding port and are impacted and crushed by the rotor with the hammerhead rotating at high speed. After many times of impact between the machine and stone breaking, the materials that can pass through the grate are discharged from the material inlet, and the materials that cannot pass through the grate are crushed again until they can pass through the grate.

Technical Parameters

Model

Feed Size

Output Size

Capacity

Motor Power

Rotor speed

Dimension

800*400

≤120

≤10

30-40

37-45

860

2.1*1.4*1.7

800*600

≤180

≤10

40-50

45-55

860

2.1*1.62*1.7

800*800

≤180

≤10

50-70

45-55

860

2.1*1.84*1.96

1010*1010

≤180

≤10

60-75

55-75

720

2.1*1.84*1.96

1200*1000

≤180

≤10

100-110

90-110

590

2.45*1.6*1.96

1200*1200

≤180

≤10

120-150

110-132

590

3*2.16*2.5

(mm)

(mm)

(t/h)

(kw)

(r/min)

(m)

High efficiency fine crusher advantages

1. Fine crusher can in operation continuously to save downtime. The impact principle is adopted for crushing, so the crushing efficiency is high, the energy consumption is small and the output is large.

2. The fine crusher has advanced feeding and discharging devices, less blockage, and less over-crushing during the crushing process. Needle flake discharge is reduced by 90%, and the grain shape is excellent, which is more suitable for the application of sand and gravel aggregates with high requirements for construction.

3. Fine crusher will not produce dust pollution when crushing large stones, and the mechanical noise is also reduced to lower decibels.

Zhengzhou, Henan, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier