Video

1 / 5

Clay Flash Dryer Machine

| Heating method : | Gas/Oil/Electric/Steam Heating |

|---|

Changzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Characteristics

Clay is an indispensable material in ceramic making. It contains very little sand and has clay, so water is not easy to pass through before it has good plasticity.

Descriptions

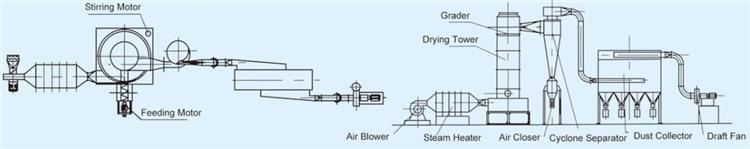

Clay Flash Dryer is continuous drying equipment specially designed for shaped cake, cream paste, and paste slurry materials. The clean heat medium goes into the drying room from the tangent direction and creates a strong rotary vortex air current when it’s in motion with the stirrer. The wet material is added to the drying room in a fixed quantity, and it will be crushed and dried under high speed stirring action. The top of the drying room has particle size classification. The big particles will be stopped by the classifier and the fine powder will be discharged from the center of the ring and collected by the cyclone separator. The big particles will return to the drying room and continue to be crushed and dried.

Principle

The hot air enters into the bottom of the drier in tangent direction. Under the driving of the stirrer, a powerful rotating wind field is formed. The paste state materials enter into the drier through the screw feeder. Under the powerful function of the stirring vanes at high-speed rotation, the materials are distributed under the function of strike, friction and shearing force. The cake state materials will be smashed and contact the hot air fully and the materials are heated and dried. The dehydrated materials will go up with the hot-air flow. The step rings will stop and keep the big particles. Small particles will be discharged out of the drier from the center of the machine and the material will be collected by cyclone separator of dust collector. The wet or big particles will be swing towards to the wall by the centrifugal force function and the materials will be crushed again after fall down to the bottom.

Features

● The raw material is processed by cutting, shearing, blowing, floating, and rotating, then becomes granulated shape and is separated greatly; the relative velocity between solid phase and gas phase is great, which strengthens the process of heating exchange.

● Designed with compact structure and require small occupied area. Machine is easy to control and maintain.

● The hot air enters into the bottom of machine and creates strong rotating airflow; it can wash out material sticking on the inside surface.

● The high temperature area is at the bottom of the machine. The heat sensitive raw material will not directly contact with heating surface. As a result, carbonization and color change problems can be solved.

● The dryer is running under negative or micro negative pressure. There is no need for other crushing machines to crush raw material, and the circumstance pollution will not occur.

● A segmenting ring and a rotational flow piece are equipped in the upper drying room in order to control granulated size and final moisture to satisfy required moisture containing rate and granulation.

Technical Advantage

● The screw blade is multi-blade structure and can be dispersed in the course of conveying. At the same time, the two spirals have the effect of cleaning each other, especially suitable for the transportation of adhesive materials and easily plugging materials.

● Main machine has stirring frequency conversion speed regulation, which is easier to control.

● The flash machine adopts special crushing device, including four layers straight knife and one layer eight word knife. There are several shredding blades at the end of each crushing knife. The crushing efficiency is greatly improved, and the material of mission block can be dispersed in time and the drying efficiency can be improved. Eight-character knife using umbrella structure (a total of four pieces of eight-character knife), blade material thickening design, so that the stirring knife strong will not break.

Application

● Organics: Atrazine (Pesticides), Cadmium Laurate, Benzoic Acid, Germicide, Sodium Oxalate, Cellulose Acetate, Organic Pigments, etc.

● Ceramics: kaoline, silicone trioxide, clay, etc.

● Dyes: Anthraquinone, Black Iiron Oxide, Indigo Pigments, Butyric Acid, Titanium Hydroxide, Zinc Sulfide, Azo Dye Intermediates, etc.

● Inorganic: Borax, Calcium Carbonate, Hydroxide, Copper Sulfate, Iron Oxide, Barium Carbonate, Antimony Trioxide, Metal Hydroxides, Heavy Metal Salts, Synthetic Cryolite, etc.

● Food: Soy Protein, Gelatinized Starch, Lees, Wheat Sugar, Wheat Starch, etc.

Schematic Structure

Technical Parameters

|

Model Item |

XSG-2 |

XSG-4 |

XSG-6 |

XSG-8 |

XSG-10 |

XSG-12 |

XSG-16 |

XSG-20 |

|

Tower Diameter (mm) |

200 |

400 |

600 |

800 |

1000 |

1200 |

1600 |

2000 |

|

Air Volume (m3/h) |

350-500 |

1150-2000 |

2450-4500 |

4450-7550 |

7000-12500 |

10000-20000 |

18000-36000 |

28200-56500 |

|

Water Evaporation (kg/h) |

12-17 |

40-70 |

80-150 |

150-250 |

230-425 |

300-600 |

600-1000 |

1000-1500 |

|

Total Power (kw) |

10 |

20 |

40 |

65 |

85 |

105 |

150 |

230 |

|

Max. Equipment Height (m) |

4.0 |

4.8 |

5.8 |

6.5 |

7.1 |

7.8 |

8.8 |

10.1 |

|

Occupied Area (m2) |

15 |

20 |

28 |

35 |

40 |

52 |

80 |

150 |

Notes:

● Water Evaporation Calculation: The air inlet temperature is 180℃ and the air temperature is 80℃.

● Customized design services available.

● The power of the machine can be reduced according to the different materials.

Raw Material Example & Characteristics

|

Raw Material Item |

Accelerant |

Oil-soluble Ink |

Phthalocyanine Blue |

Calcium Citrate |

Superfine Calcium Carbonate |

Mud Additives |

Sodium Dichloroisocyanurate |

SodiumIsocyanurate Trioxide |

|

|

Inlet Air Temperature (oC) |

150 |

150 |

120 |

150 |

140 |

160 |

200 |

180 |

150 |

|

Primary Moisture (%) |

60 |

45 |

30 |

55 |

40 |

70 |

75 |

25 |

30 |

|

Final Moisture (%) |

0.5 |

2.0 |

1.0 |

1.0 |

1.0 |

1.5 |

5.0 |

0.2-2 |

1.0 |

|

Practical Drying Capacity (kg/h) |

80-110 |

350-380 |

120-150 |

160-180 |

300-350 |

430-470 |

290-310 |

80-120 |

90-15 |

Video

Changzhou, Jiangsu, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier