Video

1 / 6

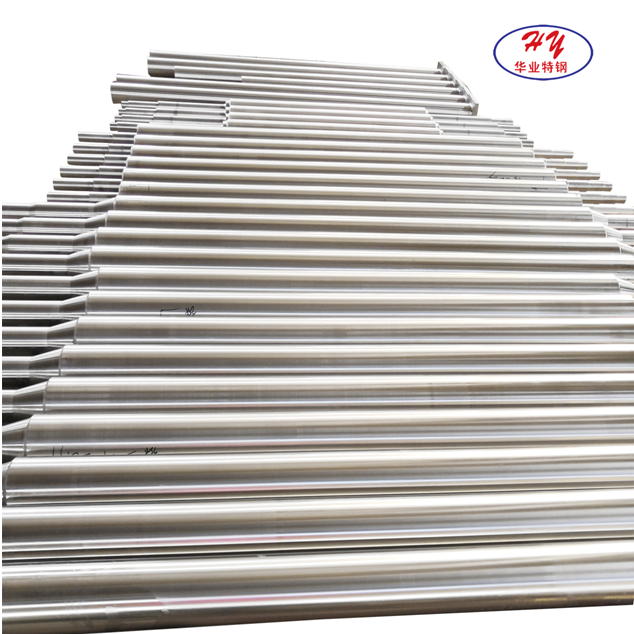

Centrifugal casting wear resistant induction heated rollers

$12.50

≥50 Others

$12.40

≥2500 Others

$12.30

≥5000 Others

| Brand Name : | HY |

|---|---|

| Brand Name : | HY |

Taizhou, Jiangsu, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Product description

Centrifugal casting heat resistant wear resistant induction heated rollers and miller roller in heat treatment furnace

1.Product description

The hot roll steel and centriufgal casting stabilizer roller are of good heat, corrosion, wear-resistant properties, working at high temperature environment on average: 800 to 1200°C, which are used in the steel mills, like CAL (continuous annealing line), CGL (continuous galvanizing line)

2.Process

Centrifugal casting for barrel/tube, forging for journal/shaft, static /investment or sand casting for cone/ trunions, welding and machining and grinding

3.Materials Standards

ANSI, ASTM, ASME, DIN, GB

Materials: High nickel and high chrome heat resistant alloys, cobalt base alloys, like HU, HT, HK, HP, HW, 24/24NbTiZr, 50Cr/50Ni (2.4813), 1.4865, 1.4849, 1.4848, 1.4410, 1.4059, 1.4841, 1.4845, 1.4852, 2.4879 or as per customer's requirements

4.inspection

We have in-house facility for each inspection: composition by spectrometer, size test, mechanical test, NDT/UT/RT/PT/MT/ET

5.Advantages

More than 30 years of professional experience and continuous R&D efforts enable us to offer better custom design and engineering advice.

Use only new raw material like nickel plate, chrome iron, cobalt, ferrotungsten to guarantee physical property and increased service life of our castings.

Owned in-house production and inspect facility to guarantee the best quality.

Experienced workers for foundry, machining and welding guarantee excellent quality and prompt delivery

6.Package

packed by seaworthy wooden case or according to buyers’ request.

7.Delivery

according to the quantity of the P.O. usually 30 days after the order is confirmed.

8.Service

We can make radiant tubes, furnace rollers and other dewaxing or sand casting products according to customers’ DRAWINGS.

The followings are photos for our factory and casting stabilizer roller products:

Video

Taizhou, Jiangsu, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier