Video

1 / 7

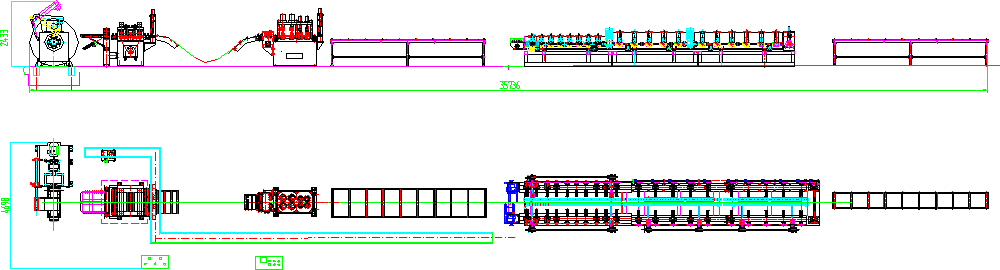

Cable Tray Cold Roll Forming Production Line

Options:

- customization available

| Brand Name : | Raintech |

|---|---|

| place of origin : | China |

Product description

Cable Tray Cold Roll Forming Production Line

1. Main technical parameters:

Material:

Coil OD:

Coil ID:

Strips width:

Strips Thickness:

Cable Tray Width:

Cable Tray Height:

Coils weight:

Electrical power:

Line Speed:

Q235 cold rolled sheet

Ф1200 mm

Ф508mm

<1250mm

0.5~2.5mm

100~800mm

50~200mm

≤10000 kg

415V,50Hz,3phase

5~15m/min

2. Production Process

Uncoiler→Leveler→Loop (storage)→Sevo Motor→Multi-stations punching machine(cutting)→Finished Products

3. Configuration and Application

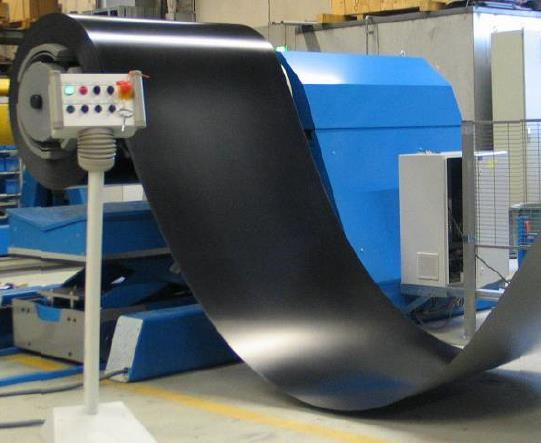

3.1 Uncoiler 1 set

The machine for single head mode (single support, four connecting rod when tight structure, when tight force to the hydraulic cylinder, adjust the fast and reliable the uncoiler as automatic decoiler, with pneumatic pressure loading device when the material after being installed on the uncoiler material shaft, in actual operation process of the whole line of decoiler shaft is rotating, uncoiler working speed can be adjust for differences in the whole line running situation in order to ensure the safety of decoiler operation decoiler is equipped with pneumatic brakes. The uncoiler also contains 4 baffles to prevent the uncoiler from loosening during the uncoiling process.

Coil ID:Ф508mm

Max. Coil OD:Ф1200mm

Max. Strips Width:1250mm

Maximum volume of aniseed bearing weight:≤10000 kg

Note: feeding trolley can be optional

3.2 Leveler 1 set

Using 7 roller leveling,2 pairs of lead roller, feed roller pneumatic clamping, frequency control, switch control

Max. speed:20m/min.

Max. Leveling coil width:1250mm,

Suitable for maximum thickness of aniseed coil:0.5~2.5mm Leveler power:aprox.7.5kw(according to final drawing)

Considering the thickness of the plate, the feeding shovel (supporting plate) and the upper pressing arm are arranged at the feeding port of the leveling machine to facilitate the smooth guiding and feeding of the coil end when it enters the leveling machine, so as to ensure the smooth feeding of the plate between the uncoiler and the leveling machine.

3.3 Loop(storage)device 1 set

Purpose: to buffer the mismatch between the uncoiling calibrating and punching machine, and to correct the deviation;Ensure the balance between the two in running speed, so that the whole line runs smoothly, complete

Structure:The material storage device consists of two parts: the arc idlers and the material supporting device. The two groups of arc idlers are placed on the two sides of the storage bin. They are composed of an arc frame and a group of rotating flexible idlers.

Photoelectric switches are installed at the two ends of the material storage pit respectively to control the plate input quantity in the silo, to ensure the material level control between the uncoiling leveler and the punching machine, so as to finally realize the speed balance between the two.

3.4 Servo feeder 1 set

Purpose: according to the actual step length required by punching, the feeding parameters of multiple groups can be set at one time, so that the feeding accuracy is convenient, fast and accurate without cumulative error Structure: composed of the servo drive system of the rack compression system.

Parameters :Maximum feeding speed:30m/min

Maximum feed width allowed:≤1250mm

Feed thickness allowed≤2.5mm

Feeding accuracy:±0.5mm/step

Brand of servo motor:Yaskawa Japan Servo Motor Power:aprox.5.5KW

3.5 Multi-station punch cutting machine 1set

Purpose: the main purpose is to finish the blanking of different holes on the profile Structure: adopting hydraulic four-column press mode, economy applicable, speed the punch for punch pattern for 6 station, contains 3 ~ 4 sets of die set (according to customer's final confirmation of the punching die set number plate type drawing final confirmation), can be continuous sheet blanking out the pass of the multi-type punching spacing in the transverse direction is adjustable, it can be finished through the electrical control system of punching step distance change.

Why Choose us?

Video

Send your inquiry to this supplier