1 / 5

Best Quality Color Steel Keel Roll Forming Machine

| Model No. : | Customized |

|---|---|

| Brand Name : | Dixin |

| Power : | 5.5+4kw |

Product description

Best Quality Color Steel Keel Roll Forming Machine

Main Parameters

| No | item | specificate |

| 1. | processing material | GI strip coils |

| 2. | processing thickness(mm) | 0.3-0.6 |

| 3. | productivity | 20-25m/min |

| 4. | roller material | Cr12 |

| 5. | roller driven | decelerating motor+chain transmission |

| 6. | number of roller stations | 10 |

| 7. | diameter of shaft | Φ40mm |

| 8. | cutting mode | hydraulic cutting device |

| 9. | length measurement | encoder |

| 10. | operation mode | button+touch screen |

| 11. | control style | PLC(brand:delta) |

| 12. | driven system | single |

| 13. | total power | 3+3kw |

| 14. | voltage | 380v 50hz or as your requirement |

Manual uncoiler-- roll forming machine-- PLC control box-- hydraulic system- output table

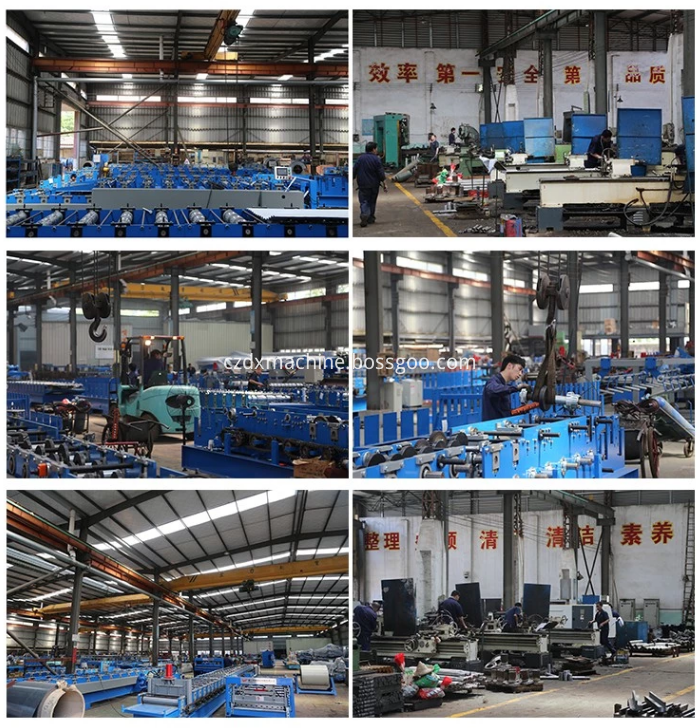

Cangzhou dixin roll forming machinery co., ltd as a manufacturer since 1996, we are specialized in manufacturing color steel forming machine, light keel machine, c&z purline machine, glazed tile forming machine, welded tube mill, steel structural floor panel roll forming machine and so on. We can provide you one station, non-stop service. Our machines have been exported to 90 countries, such as Canada, South Korea, Russia, Holland, Sri Lanka, Malaysia, India, Brazil as so on. Our company insists on the service aim: Quality First, Credit First. We believe that we can make the future cooperation and achieve win-win.

1. One 40ft container for loading one set machine with manual decoiler;

2. The whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

1.We have professional team to make different kinds of roll forming machines for our customers,

from designing, processing,assembling, debugging, delivery.

2.we can send our engineer to your site and do the training for your men. you just only bear the cost for our engineer's air ticket,visa,accormadation,food and transpotaion in your country.

3.You can send your men to our factory. we will teach them how to operate the machine without training charges.

4.Actually theres another cheap and easy way to choose. Every machine leave our factory with one book of operation manual. You can read through the manaul first ,and get familiar with the machine. Then we can get a video call,and teach you on-line how to operate the machine.

5.Apart from above training course,we also provide 1 year warranty for all the easily broken part of the machine for free and whole-life technical service support.

If there is any problems happened to the machine, we will provide solution at once.

Hope we could establish win-win business relations in the soon future!

Send your inquiry to this supplier