1 / 1

aluminum metal roofing roll forming machine for south africa

Get Latest Price

Send Inquiry

| Model No. : | as the coustomer requirement |

|---|---|

| Brand Name : | WILLING |

Zhejiang Willing Technology Co., Ltd.

You might also like

Product description

Company Information  ZheJiang Willing Technology Co., Ltd. is located in Tongxiang economic development zone, which is about 1 hours far from Shanghai. Product Description IBR ROOF FORMING MACHINE

ZheJiang Willing Technology Co., Ltd. is located in Tongxiang economic development zone, which is about 1 hours far from Shanghai. Product Description IBR ROOF FORMING MACHINE

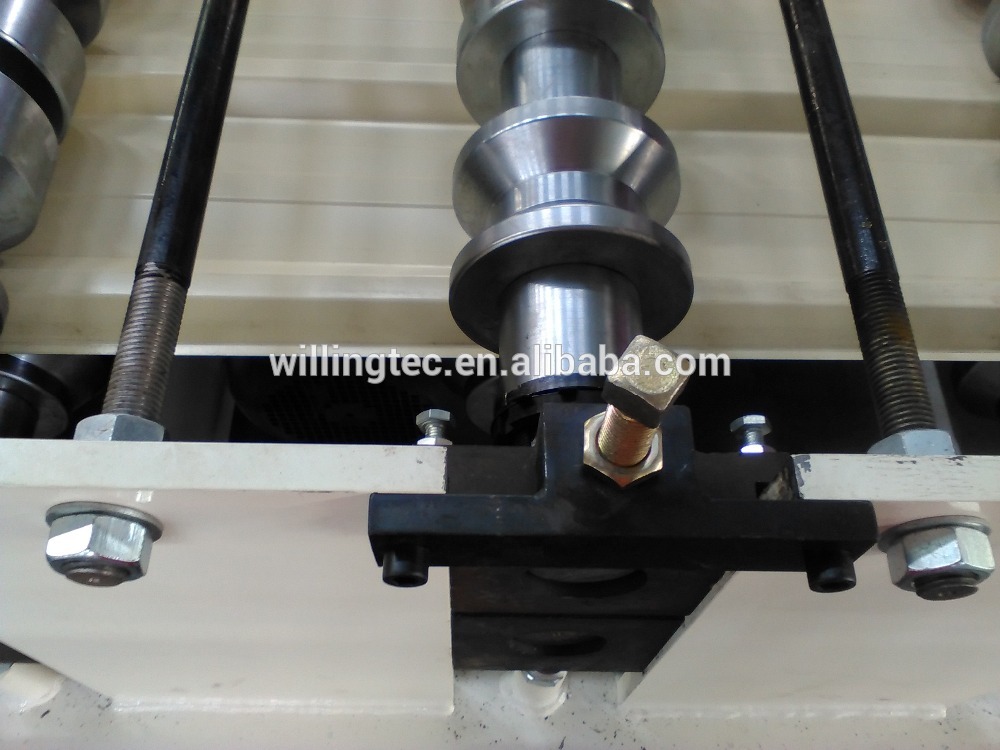

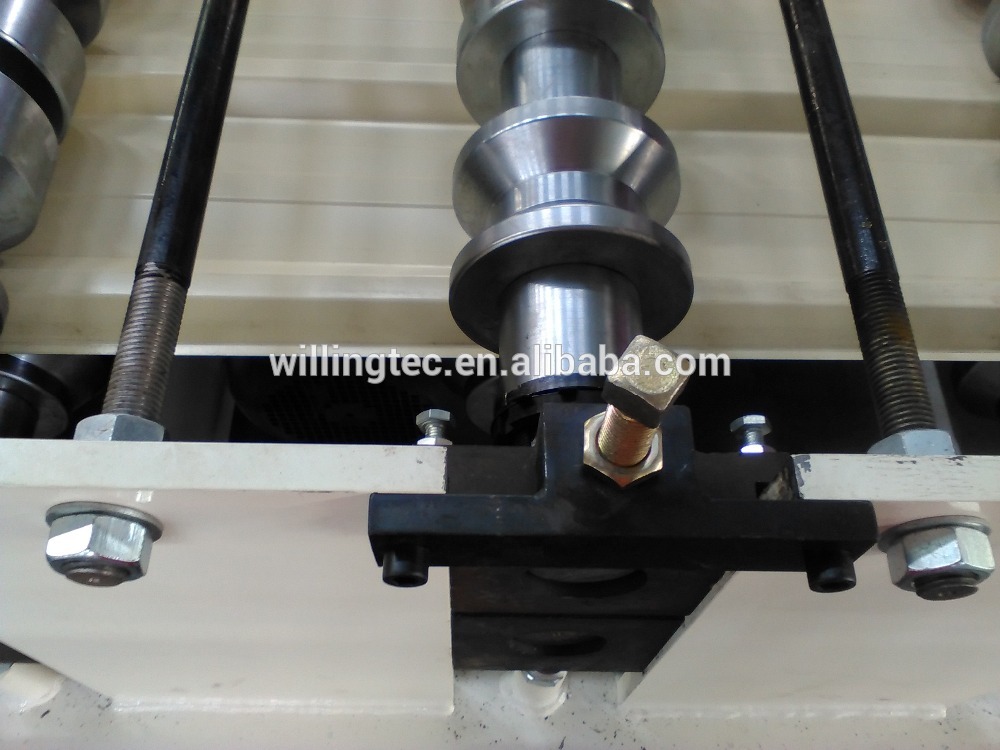

2014 hot sale roof roll forming machine good quality 1.Technical parameter: Material to be rolled PPGI or GI Thickness: 0.2-0.7mm Coil width: 1000mm Effective width: 836mm Material tension grade 550Mpa Voltage: 380V, 3ph, 50hz Main motor power: 4kw Hydraulic power: 3kw Roller: about 17 groups. Lengths: a ny length can be cutted automatically Cutting way: automatic cutting to length and hydraulic cutting Driving system: chain transmission Forming speed: About 10-12m/min Machine size: About 7500*1500*1300mm (L*W*H) Machine weight: About 6.5 tons 2. Components of machine: 1.Roller Material: high grade No.45 forged steel, Coating with hard chrome. 2.Active Shaft Material: high grade No.45 carbon wrought steel, improved the integrated mechanic feature of the shaft. 3.Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan. 4.Other Elements: from famous suppliers in China. 5.Cutter Blade: Cr12 mould steel with quenched treatment. 3. Process flow: Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic Cutting – product to run out table 4. Details of the machine and wall panel

4. Details of the machine and wall panel  1.Manual decoiler 1> Inner diameter:450-550mm 2>Outer diameter: 1500mm 3>Coil width:1250m 4>capacity: 5T

1.Manual decoiler 1> Inner diameter:450-550mm 2>Outer diameter: 1500mm 3>Coil width:1250m 4>capacity: 5T  2. Forming device

2. Forming device

3.Hydraulic cutting 1>automatic forming, high level safety factor. 2>easy to control, hydraulic cutting after forming

3.Hydraulic cutting 1>automatic forming, high level safety factor. 2>easy to control, hydraulic cutting after forming  4.Control system (touch screen and text screen for choice) 1>Screen:Delta touch screen 2>PLC: Delta 3>automatic length and quantity measurement 4>cutting to length and stop when required quantity is achieved.

4.Control system (touch screen and text screen for choice) 1>Screen:Delta touch screen 2>PLC: Delta 3>automatic length and quantity measurement 4>cutting to length and stop when required quantity is achieved.

We customize your machines! To customize machine, we would love to know:

We customize your machines! To customize machine, we would love to know:

1. Profile drawing

2. Raw material: the width(914mm-1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage:220v/380 or designed on your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ stacker Have no idea about them?

We will be glad to recommend the lacol popular profile for you----Just let us know your country! Packaging & Shipping

Packaging & Shipping

ZheJiang Willing Technology Co., Ltd. is located in Tongxiang economic development zone, which is about 1 hours far from Shanghai. Product Description IBR ROOF FORMING MACHINE

ZheJiang Willing Technology Co., Ltd. is located in Tongxiang economic development zone, which is about 1 hours far from Shanghai. Product Description IBR ROOF FORMING MACHINE

2014 hot sale roof roll forming machine good quality 1.Technical parameter: Material to be rolled PPGI or GI Thickness: 0.2-0.7mm Coil width: 1000mm Effective width: 836mm Material tension grade 550Mpa Voltage: 380V, 3ph, 50hz Main motor power: 4kw Hydraulic power: 3kw Roller: about 17 groups. Lengths: a ny length can be cutted automatically Cutting way: automatic cutting to length and hydraulic cutting Driving system: chain transmission Forming speed: About 10-12m/min Machine size: About 7500*1500*1300mm (L*W*H) Machine weight: About 6.5 tons 2. Components of machine: 1.Roller Material: high grade No.45 forged steel, Coating with hard chrome. 2.Active Shaft Material: high grade No.45 carbon wrought steel, improved the integrated mechanic feature of the shaft. 3.Electric Elements: PLC control panel, transducer imported from Mitsubishi of Japan. 4.Other Elements: from famous suppliers in China. 5.Cutter Blade: Cr12 mould steel with quenched treatment. 3. Process flow: Decoiler -- Feeding & Guiding -- Roll forming---Hydraulic Cutting – product to run out table

4. Details of the machine and wall panel

4. Details of the machine and wall panel  1.Manual decoiler 1> Inner diameter:450-550mm 2>Outer diameter: 1500mm 3>Coil width:1250m 4>capacity: 5T

1.Manual decoiler 1> Inner diameter:450-550mm 2>Outer diameter: 1500mm 3>Coil width:1250m 4>capacity: 5T  2. Forming device

2. Forming device

3.Hydraulic cutting 1>automatic forming, high level safety factor. 2>easy to control, hydraulic cutting after forming

3.Hydraulic cutting 1>automatic forming, high level safety factor. 2>easy to control, hydraulic cutting after forming  4.Control system (touch screen and text screen for choice) 1>Screen:Delta touch screen 2>PLC: Delta 3>automatic length and quantity measurement 4>cutting to length and stop when required quantity is achieved.

4.Control system (touch screen and text screen for choice) 1>Screen:Delta touch screen 2>PLC: Delta 3>automatic length and quantity measurement 4>cutting to length and stop when required quantity is achieved. We customize your machines! To customize machine, we would love to know:

We customize your machines! To customize machine, we would love to know:1. Profile drawing

2. Raw material: the width(914mm-1250mm?), thickness(0.3-0.7mm?), and yield strength of steel coil.

3. Voltage:220v/380 or designed on your requirement

4. Configuration requirement: Hydraulic or manual decoiler/ stacker Have no idea about them?

We will be glad to recommend the lacol popular profile for you----Just let us know your country!

Packaging & Shipping

Packaging & Shipping

Send your inquiry to this supplier

Send Inquiry