Video

1 / 5

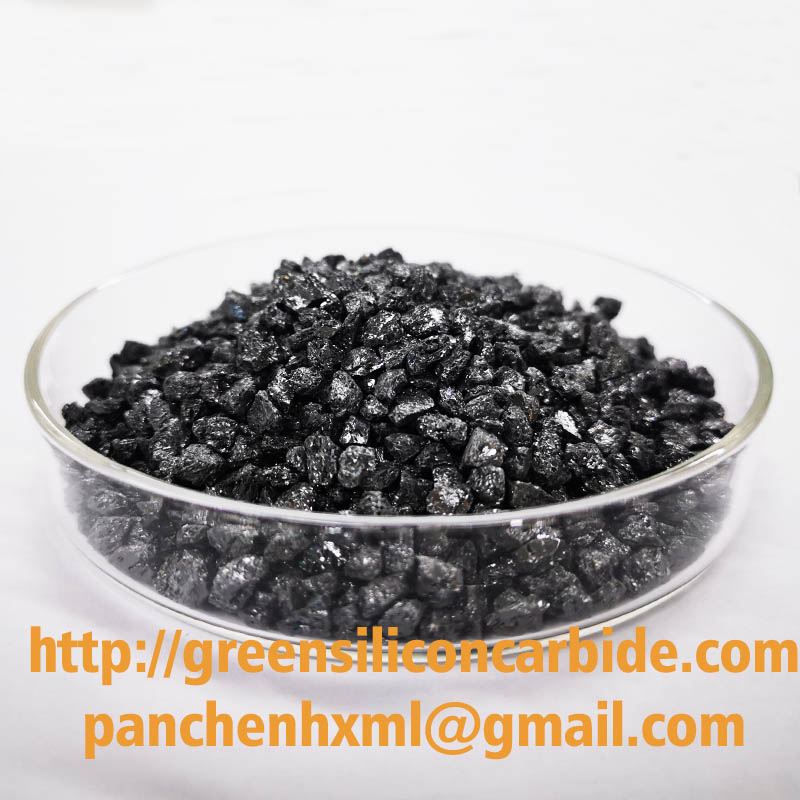

97% Silicon carbide slag 1-5mm 1-10mm for ladle lining

$1100.00

≥1 Metric Ton

Options:

- 0-1mm

- 325F

- 0-0.25mm

- 0.5-1mm

- 3-5mm

- 1-10mm

- 1-5mm

- 1-3mm

- 1-2mm

- 200F

| Model No. : | 1-5mm |

|---|---|

| Brand Name : | HAIXU ABRASIVES |

| place of origin : | China |

Product description

97% Silicon carbide slag 1-5mm 1-10mm for ladle lining

Black silicon carbide sand is made by smelting quartz sand and petroleum coke in a resistance furnace at high temperature (about 2700 ℃). It is a black opaque body with a Mohs hardness of 9.2. Black silicon carbide has the characteristics of being fragile and sharp. Black silicon carbide has a high thermal conductivity, low thermal expansion rate, and excellent thermal shock resistance and corrosion resistance chemical stability.

Black silicon carbide sand 1-3mm Features:

1. Good wear resistance and wear resistance. Black silicon carbide itself is a good wear-resistant material. It can not only withstand the erosion of flowing high-temperature molten iron in the field of refractory materials, but also has high-temperature thermal shock resistance. The Vickers hardness of silicon carbide at room temperature is 3100-3200kg/mm2, which slightly decreases at high temperatures. However, even at 1200 degrees, it can still maintain a microhardness of 950-1000kg/mm2.

2. High refractory temperature. The melting point of black silicon carbide is 2600 ℃. It is free at a high temperature of 2300 ℃, with a working temperature of up to 1850 ° C. It can maintain good high-temperature and physicochemical properties at a high temperature of 1600 ℃.

3. Oxidation resistance: When the black silicon carbide casting material is within 1400 ℃, a silicon dioxide film will be formed on the outside of the particles to prevent further oxidation of silicon carbide. Made into refractory products, they can resist the erosion of oxidizing media such as oxygen and water vapor.

4. Corrosion resistance: Black silicon carbide has excellent acid and alkali resistance. It can effectively resist the erosion of corrosive substances such as slag and metal oxides.

5. High thermal conductivity: Black Silicon carbide has good thermal conductivity, and the heat inside the furnace can be evenly distributed and quickly transmitted. Thus it improves the thermal efficiency of furnace equipment.

Physical indexes

|

Hardness(Mohs scale) |

9.2 |

|

Melting Point: |

dissociated at about 2300 °C |

|

Maximum service temperature: |

1900℃ |

|

Specific Gravity: |

3.2-3.45 g/cm3 |

|

Bulk density(LPD): |

1.2-1.6 g/cm3 |

|

Color: |

Black |

|

Particle shape: |

Hexagonal |

|

Modulus of Elasticity |

58-65x106 psi |

|

Coefficient of Thermal Expansion |

3.9-4.5 x10-6/ ℃ |

|

Thermal Conductivity |

71-130 W/MK |

Chemical content:

|

Spec. |

Purity |

F.C |

Fe2O3 |

Moisture |

|

SiC86 |

≥86% SiC |

≤2.4% |

≤ 2.0% |

≤ 0.2% |

|

SiC88 |

≥ 88% SiC |

≤ 2.3% |

≤ 2.0% |

≤ 0.2% |

|

SiC90 |

≥ 90% SiC |

≤ 2.0% |

≤ 1.8% |

≤ 0.2% |

|

SiC92 |

≥ 92% SiC |

≤ 1.8% |

≤ 1.7% |

≤ 0.2% |

|

SiC93 |

≥93% SiC |

≤ 1.8% |

≤ 1.6% |

≤ 0.2% |

|

SiC95 |

≥ 95% SiC |

≤ 1.0% |

≤ 1.3% |

≤ 0.2% |

|

SiC97 |

≥ 97% SiC |

≤ 0.8% |

≤ 1.2% |

≤ 0.2% |

|

SiC97.5 |

≥97.5% SiC |

≤ 0.8% |

≤ 0.9% |

≤ 0.2% |

|

SiC98 |

≥ 98% SiC |

≤ 0.5% |

≤ 0.5% |

≤ 0.2% |

Specifications:

|

Black silicon carbide sand size |

Particle size distribution |

|

0-1mm |

+1mm 10% max |

|

0.2-0.5mm |

-0.2mm 10% max +0.5mm 10% max |

|

1-2mm |

-1mm 10% max +3mm10% max |

|

1-3mm |

-1mm 10% max +3mm10% max |

|

3-5mm |

-3mm 10% max +5mm10% max |

|

100F |

+0.150mm 10% max |

|

200F |

+0.075mm 10% max |

|

325F |

+0.045mm 10% max |

Customized sizes are available upon request.

Application:

1. Castable and repair materials for kiln equipment in the steel, glass, power, chemical, and ceramic industries. Such as high-temperature kilns in steelmaking furnaces, ironmaking furnaces, and steel ladles. Non ferrous metal smelting kilns and converters. Glass furnaces, ceramic tunnel kilns, shuttle kilns. Rotary kilns and gypsum kilns for cement and other building materials. High temperature equipment such as catalytic cracking furnaces and gasifiers.

2. Ceramic fillers and aggregates for refractory ceramic parts and thermal components.

3. Deoxidizer for steelmaking furnace.

4. Unshaped refractory materials and shaped refractory materials. Such as fire brick &tiles in heat exchanger. Tiles and Mortars in blast furnace, steel ladle, Crucibles, etc.

5. Thermal resistance foamglass, etc.

Video

Send your inquiry to this supplier