1 / 6

25mm plastic pvc foam furniture board making machine

$90000.00

≥1 Set/Sets

$85000.00

≥5 Set/Sets

Output (kg/h):

- 280

- 300

- 350

Options:

- SJSZ80/156

Send Inquiry

| application : | Sheet |

|---|

More

zhangjiagang sevenstars machinery co.,ltd

You might also like

Product description

Product Description

General description

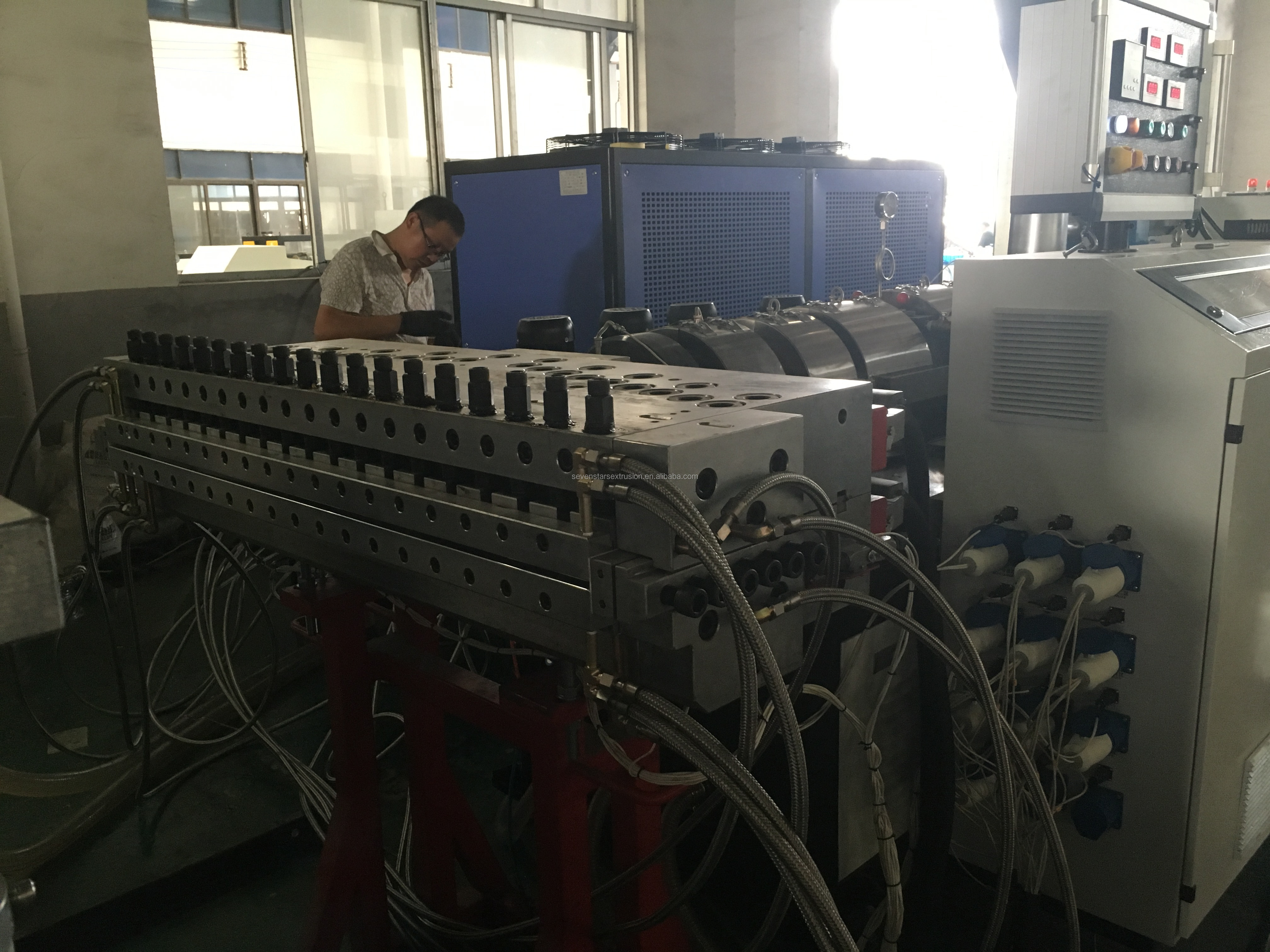

Our PVC foam board machine includes the special Twin-screw extruder, mould and other auxiliary machines. We use twin-screw extruder with compact structure, superior performance. Besides the screw and barrel and die are designed by our company and made in world famous manufacturers. And use the high-performance alloy steel for professional processing. So the machine has the advantages of uniform plasticizing, stable extrusion, high output, and long life. We can supply you the best material formulation and all of technology. We have several thousand kinds of formula through 15 years’ researches. PVC or WPC foam board production line with big output, stable extrusion, high foaming, good and wear-resisting surface and so on.

Our PVC foam board machine includes the special Twin-screw extruder, mould and other auxiliary machines. We use twin-screw extruder with compact structure, superior performance. Besides the screw and barrel and die are designed by our company and made in world famous manufacturers. And use the high-performance alloy steel for professional processing. So the machine has the advantages of uniform plasticizing, stable extrusion, high output, and long life. We can supply you the best material formulation and all of technology. We have several thousand kinds of formula through 15 years’ researches. PVC or WPC foam board production line with big output, stable extrusion, high foaming, good and wear-resisting surface and so on.

25mm plastic pvc foam furniture board making machine

Advantages of PVC / WPC Foam Board

1, Environment friendly

2, Recycled available

3, Water proof

4, Anti-corrosion

5, Deformation hard .

FLOW CHART OF PRODUCING

Crusher (crushing the edge o board trimmed) → Miller (milling the scraps into powder → Mixer (mixing the main materials and additives) → SJSZ 80- 156 Twin Conical Screws Extruder → Mould → Calibration Table → Cooling Bracket → Hual-off Machine → Edge Cutting → Cutter → Stacker .

Crusher (crushing the edge o board trimmed) → Miller (milling the scraps into powder → Mixer (mixing the main materials and additives) → SJSZ 80- 156 Twin Conical Screws Extruder → Mould → Calibration Table → Cooling Bracket → Hual-off Machine → Edge Cutting → Cutter → Stacker .

Specification

25mm plastic pvc foam furniture board making machine

Board characteristics

PVC wpc crust foam board has such characteristics as sound separation, sound absorption, heat separation, temperature-keeping,etc.

The material is incombustible, it is safe for use.

All series of products have property of moisture proof, mildew proof, water resistance; its vibration resistant effect is good.

All series of products have property of weathering proof, its luster may remain forever, and it is not easy to be ageing.

This product is light, storage & transport, construction are rather convenient.

This product can be worked with normal tools for wooden material.

Drilling, sawing, nail, planning, bonding can be conducted like wooden material.

It is suitable for thermal shaping, thermal bending and fold processing.

It can be welded; it can also be bonded with other pvc material.

The surface of this product is smooth, it can be printed. (Clean the surface before printing.)

PVC wpc crust foam board has such characteristics as sound separation, sound absorption, heat separation, temperature-keeping,etc.

The material is incombustible, it is safe for use.

All series of products have property of moisture proof, mildew proof, water resistance; its vibration resistant effect is good.

All series of products have property of weathering proof, its luster may remain forever, and it is not easy to be ageing.

This product is light, storage & transport, construction are rather convenient.

This product can be worked with normal tools for wooden material.

Drilling, sawing, nail, planning, bonding can be conducted like wooden material.

It is suitable for thermal shaping, thermal bending and fold processing.

It can be welded; it can also be bonded with other pvc material.

The surface of this product is smooth, it can be printed. (Clean the surface before printing.)

|

Model

|

Main motor

|

capacity

|

Product width

|

Product thickness

|

|

SJSZ80/156

|

75kw

|

350kg/h

|

915-1220mm

|

3-45mm

|

|

SJSZ80/173

|

75kw

|

500-600kg/h

|

1560-1830mm

|

3-45mm

|

|

SJSZ92/188

|

110kw

|

500-600kg/h

|

1560-1830mm

|

3-45mm

|

Recommend Products

Recommended by seller

Contact us

Packing & Delivery

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.

Company Profile

Zhangjiagang Sevenstars Machinery Co., Ltd. is a group company. We devote ourselves to the development, research and production of plastic machines and liquid food and beverage packing and filling machines.

For plastic machines, our main products include:

big-mouth PVC pipe extrusion production lines,

PE big-mouth for gas,

water supply extrusion production lines,

PET bottle recycling line

PE/PP film recycling line

PVC/WPC foam board extrusion line

PVC/WPC profile extrusion line

PP hollow sheet extrusion line

HDPE/LDPE pipe extrusion line

PPR PIPE extrusion line

plastic extruders,

high speed mixers and various plastic auxiliary machines.

Please feel free to contact us for further details. We are looking forward to forming a profitable business relationship with your company in the near future. We welcome you to visit our company at any time.

FAQ

Why choose us?

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

1. Low cost

* All the machine ,we make it ourself to reduce the cost of our customer.

2. Genuine product with excellent quality

* We choose our material very strict.

* All the material come to our factory must pass the quality test

* Substandard goods are returned to the supplier.

3. Engerneers available to serve oversea

4. Quick delivery

* The company provide just in time delivery with its streamlined supply chain.

5. Cost saving

* Se take strong attention to every detail in the manufacturing process.

* The quality control in our factory is very strict.

* All defective semi-manufactures must be treated again or reject.

* All the machine must be checked out ,then delivered to our customer.

* All about that pushing up the price,but get good quality machine.

* What we want to do is give our customer a good quality product with stable working and long lived.

Send your inquiry to this supplier

Send Inquiry