1 / 1

Zirconia Ceramic Cut-off Valve for Sewage Treat

| Model No. : | customized |

|---|---|

| Brand Name : | Mingrui |

| Color : | White,Black |

Product description

Product Description:

Zirconia Ceramic Cut-off Valve for Sewage Treatment Equipment

Valves are classified into gate valves, cut-off valves, cock valves, ball valves, butterfly valves, check valves, regulating valves, etc., according to the use and principle of the valves. Zirconia ceramics, because of their super wear resistance, not afraid of the scraping and friction of the particles in the sewage.become a great material used as a ceramic valve. Ceramic valves are more resistant to corrosion resistance than metal valves, especially in corrosive sewage, and the life of metal materials is much less than zirconia ceramic valves.

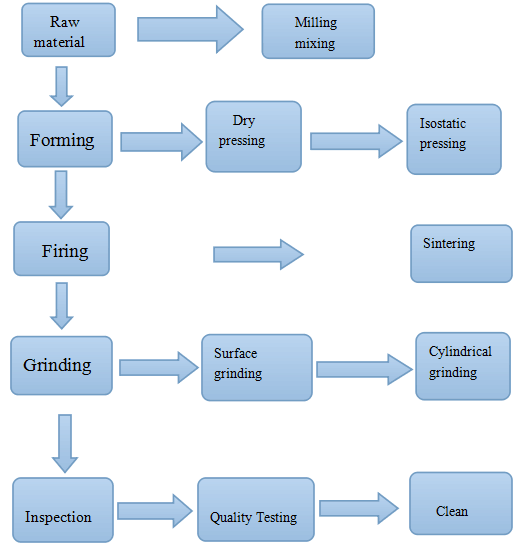

Production process

The products made by zirconia and alumina products have excellent performances,the properties of our products:

|

Properties |

Units |

95 Alumina |

99 Alumina |

ZrO2 |

|

Density |

g / cm³ |

3.65 |

3.9 | 5.95-6.05 |

|

Water absorption |

% |

0 | 0 | 0 |

|

Coefficient of thermal expansion |

10-6/K |

7.9 |

8.5 | 10.5 |

|

Modulus of Elasticity Young's Mod |

GPa |

280 | 340 | 210 |

|

Poisson's ratio |

/ | 0.21 | 0.23 | 0.3 |

| HV Hardness |

MPa |

1400 | 1700 | 1300-1365 |

|

Flexural Strength @ room temperature |

MPa |

280 | 320 | 950 |

|

Flexural Strength @700°C |

MPa |

220 | 230 | 210 |

|

Compressive Strength @ room temperature |

MPa |

2000 | 2200 | 2000 |

|

Fracture Toughness |

MPa *m 1/2 |

3.8 | 4.3 | 10 |

|

Heat conductivity @ room temperature |

W/ m*k |

18-25 |

26-30 |

2-2.2 |

|

Electrical Resistivity @ room temperature |

Ω*mm2 /m |

10^15 |

10^16 |

10^15 |

|

Max use temperature |

°C |

1850 | 2200 | 1500 |

|

Resistance to acid alkaline |

/ |

high |

high |

high |

|

Dielectric Constant |

/ |

9.5 | 9.8 | 26 |

|

Dielectric Strength |

KV/mm |

10 | 10 | 10 |

|

Thermol Shock Resistance |

△ T ( °C ) |

220 | 190 | 280-350 |

|

Tensile Strength @ 25 °C |

MPa |

200 | 248 | 260 |

|

Thermal Conductivity(25℃) |

W/m·K |

30 | 35 | 3 |

Company information:

Mingrui has professional OEM experience in manufacturing industrial ceramic parts for so many years. And

very advanced technologies in the production of Zirconia Ceramic Rod and Alumina Ceramic Rod, Zirconia

Ceramic Ring and Alumina Ceramic Ring, Zirconia Ceramic Tube and Alumina Ceramic Tube, Ceramic

Pin, Ceramic Shaft , Ceramic Plate And Block, Ceramic Sleeve, Ceramic Injector Nozzle, Ceramic

Dispensing Valve, Ceramic Injection Pump, Ceramic Plunger Pump, Ceramic Piston, Ceramic Stick ,

Ceramic Washer, and Semiconductor Industry Ceramics, Machinable Ceramic Part, Ceramic Electronics

Accessories, etc..

They are applicable to Electrical, Appliance, Mining, Oil & Gas, Energy & Power, Food & Medical, Agriculture, Aerospace,

even other high-end fields.

We can make the product according to your drawings, custom the size, shape, color and thickness etc..

Our products with some certificates, such as SGS, CE, TUV, etc..

To find out more, contact us right now without hesitating!

Workshop overview:

We have almost all the precision processing machines of ceramic products:

Quality assurance:

We have complete testing equipment and good after-sales service:

Our certifications:

Delivery:

we will give you quick response to solve your problems at the first time. we also improved our logistics service system so that you can enjoy a one to one intimate service.Each of our product is elaborately packed to insure it is intact when arriving;We cooperate with professional logistics such as DHL UPS,Fedex,etc.and offer realtime tracking data to our customers in time.

FAQ;

1.are you manufacturer or trade company?

We are a factory with our own workshop located in Chang'an Town ,Dongguan City,which is known as

[The hometown of mould",We have strong precision processing ability and excellent matching manufacturer.

2.Can you provide the free samples?

Yes, we can provide the sample free of charge if we have the stock product as customer's requirements, but the freight is on your side.

3.Can you accept OEM&ODM?

Yes, we can produce the products according to your demand and drawing.

Send your inquiry to this supplier