1 / 5

Worm Gear System Universal Testing Machine

| Model No. : | WAW-1000C |

|---|---|

| Brand Name : | Chenda |

| Type : | Universal Testing Machine |

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Product description

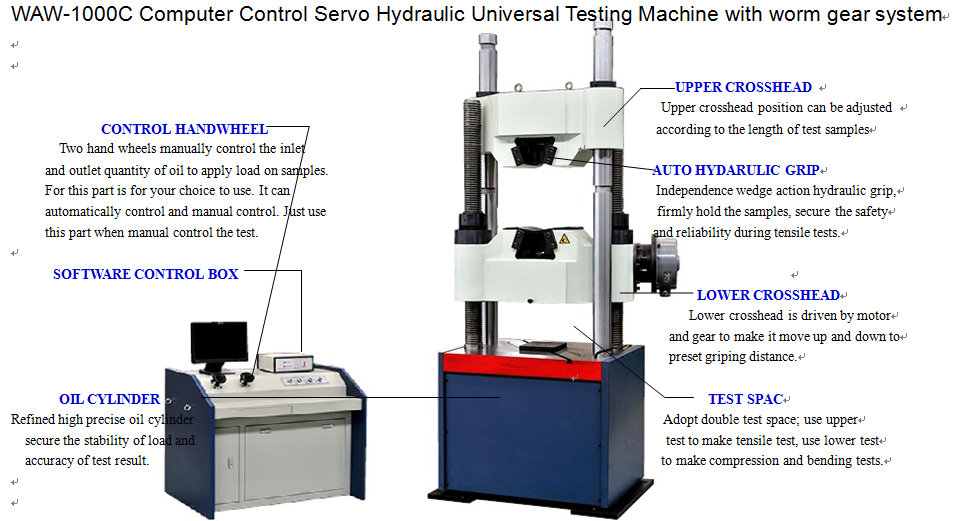

WAW-1000C Computer control servo hydraulic universal testing machine adopts under fuel tank host structure. Mainly used for metal and nonmetal material product tensile, compression and bending mechanical test.

If this series testing machine equipped with environment device also can do test with this environment. For example: high temperature tensile testing machine, low temperature tensile and compression testing machine.

It is widely used for the industry of iron, steel, metallurgy and building materials also inspection center, roads and bridges,research institutes, universities and other department.

Main technical specifications:

1> Host:The host adopts under fuel tank host structure. The tensile space is on the upper of the host. The compression and bending test space is between the lower crosshead and test table.

2> Transmission system:

Using the oil pressure transduce to measure the force indirectly. The worm gear transmission device system to adjust the test space. It do not need the screw rotating when you adjust the test space. This made the transmission system and the positioning system separated completely. To ensure the concentricity and durability of the upper and lower jaws.

3> Software:

Using the Max. Test software

Details technical specification:

|

No. |

Technical |

Specification |

|

1 |

Max test force kN |

1000 |

|

2 |

relative error of test force |

≤±1% |

|

3 |

Measurement range of test force |

2%~100% |

|

4 |

stress control range(N/mm2·S-1) |

2~60 |

|

5 |

strain control range |

0.00025/s~0.0025/s |

|

6 |

displacement control range (mm/min) |

0.5~50 |

|

7 |

Clamping ways |

Hydraulic clamping |

|

8 |

Round specimen fixture mm |

Φ13~Φ60 |

|

9 |

Flat specimen fixture mm |

0-40 |

|

10 |

The width of flat specimen mm |

80 |

|

11 |

Max. Tensile test space mm |

850 |

|

12 |

Max. Compression test space mm |

650 |

|

13 |

Control cabinet packing Dimensions mm |

1280*850*1500 |

|

14 |

Host packing Dimension mm |

1200*900*2700 |

|

15 |

Motor Power kW |

2.5 |

|

16 |

Gross weight kg |

3800 |

|

17 |

Column clearance (mm) |

620 |

|

18 |

Upper and lower platens size mm |

200*200 |

|

19 |

Maximum piston stroke mm |

200 |

|

20 |

Piston movement speed mm/min |

80 |

Standard delivery:

|

No. |

Name |

Specification |

quantity |

Remark |

|

1 |

Host |

|

1set |

Chenda |

|

2 |

Servo control oil source |

|

|

Chenda |

|

3 |

Control Cabinet |

|

1set |

Chenda |

|

4 |

Measurement system |

|

1set |

Chenda |

|

5 |

Extensometer |

|

1 |

Changchun |

|

6 |

Oil pressure transducer |

|

1Set |

Jiangsu |

|

7 |

Optical encoder |

|

1set |

Jinan |

|

8 |

Computer |

|

1set |

Lenovo |

|

9 |

Printer |

|

1set |

HP |

|

10 |

Round specimen specification mm |

Φ13~Φ26,Φ26~Φ40,Φ40~Φ60, |

Each of the specification 1 |

Standard delivery is 3 sets tensile fixtures. The client's can choice according to your requirement |

|

11 |

Flat specimen specification mm |

0~20,20~40 |

Each of the specification 1 |

|

|

12 |

Compression fixture mm |

|

1set |

Chenda |

|

13 |

Bending fixture |

|

1set |

Chenda |

|

14 |

Pump |

|

|

MARZOCCHI |

|

15 |

Motor |

|

|

WANNAN |

|

16 |

Accompany documents |

User manul, packing list Certificate |

|

|

Detail:

Photo:

Working shop:

Jinan, Shandong, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier