1 / 2

wood pellets processing line with ce

Get Latest Price

Send Inquiry

| Model No. : | wood pellet line |

|---|---|

| Brand Name : | hengmu |

Henan Hengmu Machinery Co.,Ltd.

You might also like

Product description

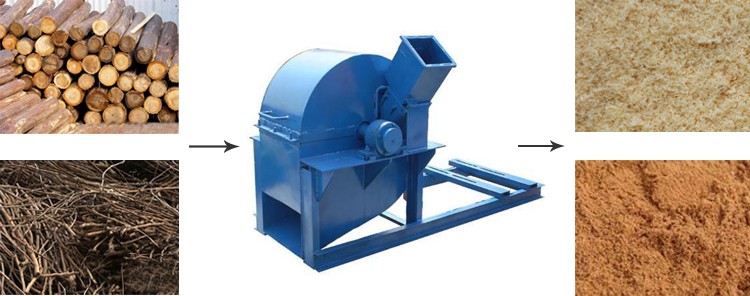

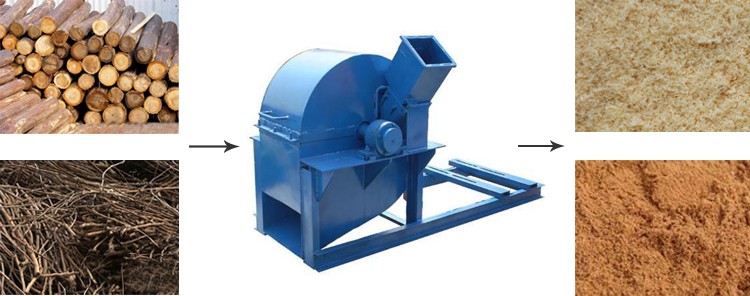

Raw materials wood pellets processing line with ce Raw material: such as sawdust, wood shavings, wood chips or wood logs, any forestry wastes or biomass straws, stalks, etc.  details of wood line wood pellet production line consists of eight sections: raw materials---crushing---drying---pelleting---cooling---packing 1.The crushing process of High quality biomass wood pellet production line

details of wood line wood pellet production line consists of eight sections: raw materials---crushing---drying---pelleting---cooling---packing 1.The crushing process of High quality biomass wood pellet production line  2.The drying process of wood pellets processing line

2.The drying process of wood pellets processing line

3.Pelleting section of wood pellets processing line

Pelleting is a main step of any pelleting plant. It is a process of converting any powder to solid shape called pallet. In this process the powder material is extruded through a well designed die with the help of rollers to convert it in to pallets. The quality & production of pallet mill depends on so many parameters.

4.Cooling Section of wood pellets processing line

Cooling is a process of removing heat. As we know during conditioning we add heat and moisture and also through palleting process heat generates by extrusion process. But the pallet should have a standard moisture and heat to attain its life of storage and make it safe from fungus. So we have to remove extra heat and moisture from the pallet. All this is done with the help of a well designed counter flow cooler.

5.Packing Section of wood pellets processing line

The end of process in every plant is bagging also called packing. After screening the finished products are filled in to bags. In small and medium plants, bagging can be carried out manually but for higher production it is batter to go for electronic bagging machine

6. Auxiliary section of wood pellets processing line

9.1 pulse dust collector

9.2 air compressor

9.3 pipeline and accessories Diameter

Diameter

certifications

our service

our service

Pre-Sales Service Workshop * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service Sample of simple line * Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. packing&delivery

Pre-Sales Service Workshop * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service Sample of simple line * Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. packing&delivery

related products

Poultry livestock feed pellet mill machine line for animal farm 91.8% Response Rate flat die wood biomass grass pellet mill with ce approved 91.8% Response Rate premix powder mixing machine 91.8% Response Rate

Poultry livestock feed pellet mill machine line for animal farm 91.8% Response Rate flat die wood biomass grass pellet mill with ce approved 91.8% Response Rate premix powder mixing machine 91.8% Response Rate

details of wood line wood pellet production line consists of eight sections: raw materials---crushing---drying---pelleting---cooling---packing 1.The crushing process of High quality biomass wood pellet production line

details of wood line wood pellet production line consists of eight sections: raw materials---crushing---drying---pelleting---cooling---packing 1.The crushing process of High quality biomass wood pellet production line  2.The drying process of wood pellets processing line

2.The drying process of wood pellets processing line

Pelleting is a main step of any pelleting plant. It is a process of converting any powder to solid shape called pallet. In this process the powder material is extruded through a well designed die with the help of rollers to convert it in to pallets. The quality & production of pallet mill depends on so many parameters.

Cooling is a process of removing heat. As we know during conditioning we add heat and moisture and also through palleting process heat generates by extrusion process. But the pallet should have a standard moisture and heat to attain its life of storage and make it safe from fungus. So we have to remove extra heat and moisture from the pallet. All this is done with the help of a well designed counter flow cooler.

The end of process in every plant is bagging also called packing. After screening the finished products are filled in to bags. In small and medium plants, bagging can be carried out manually but for higher production it is batter to go for electronic bagging machine

9.1 pulse dust collector

9.2 air compressor

9.3 pipeline and accessories

Diameter

Diameter

our service

our service

Pre-Sales Service Workshop * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service Sample of simple line * Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. packing&delivery

Pre-Sales Service Workshop * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service Sample of simple line * Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. packing&delivery

Poultry livestock feed pellet mill machine line for animal farm 91.8% Response Rate flat die wood biomass grass pellet mill with ce approved 91.8% Response Rate premix powder mixing machine 91.8% Response Rate

Poultry livestock feed pellet mill machine line for animal farm 91.8% Response Rate flat die wood biomass grass pellet mill with ce approved 91.8% Response Rate premix powder mixing machine 91.8% Response Rate Send your inquiry to this supplier

Send Inquiry