Video

1 / 4

Waste Tire Recycling Equipment Plant

Get Latest Price

Model:

- JN-1000

Send Inquiry

| Model No. : | JN-1000 |

|---|---|

| Brand Name : | SUMAC |

| place of origin : | China |

More

SUMAC AUTO RECYCLING EQUIPMENT CO., LTD

You might also like

Product description

Introduction

Tire rubber recycling plant is a great solution to the problem of tire waste. This technology is not only environmentally friendly but also energy-saving. The tire recycling process converts waste tires into rubber granules, separated fibers, and steel wires without causing pollution.

The tire recycling plant has a broad market prospect due to its various benefits. Recycling waste tires is essential to protect the environment as dumped tires can lead to dangerous environmental situations like tire fires. Therefore, the need for tire recycling plants is increasing, and the tire recycling plant technology is becoming more advanced and efficient.

Additionally, tyre recycling production line is designed to meet different customer requirements. The experts who design these plants ensure that the entire process is customized according to the customer's specific needs. This means that the tire recycling process is not only efficient but also cost-effective.

Tire rubber recycling plant is a great solution to the problem of tire waste. This technology is not only environmentally friendly but also energy-saving. The tire recycling process converts waste tires into rubber granules, separated fibers, and steel wires without causing pollution.

The tire recycling plant has a broad market prospect due to its various benefits. Recycling waste tires is essential to protect the environment as dumped tires can lead to dangerous environmental situations like tire fires. Therefore, the need for tire recycling plants is increasing, and the tire recycling plant technology is becoming more advanced and efficient.

Additionally, tyre recycling production line is designed to meet different customer requirements. The experts who design these plants ensure that the entire process is customized according to the customer's specific needs. This means that the tire recycling process is not only efficient but also cost-effective.

Product specifications

Raw material: waste tires, outer diameter of waste tire less than 1200mm.

Remove double sides of steel tire beads

Final product: 50x50 mm rubber chips

Capacity: about 3000~4000 kg/hour

Automatic feeding and discharging

Electric buttons control system or PLC system

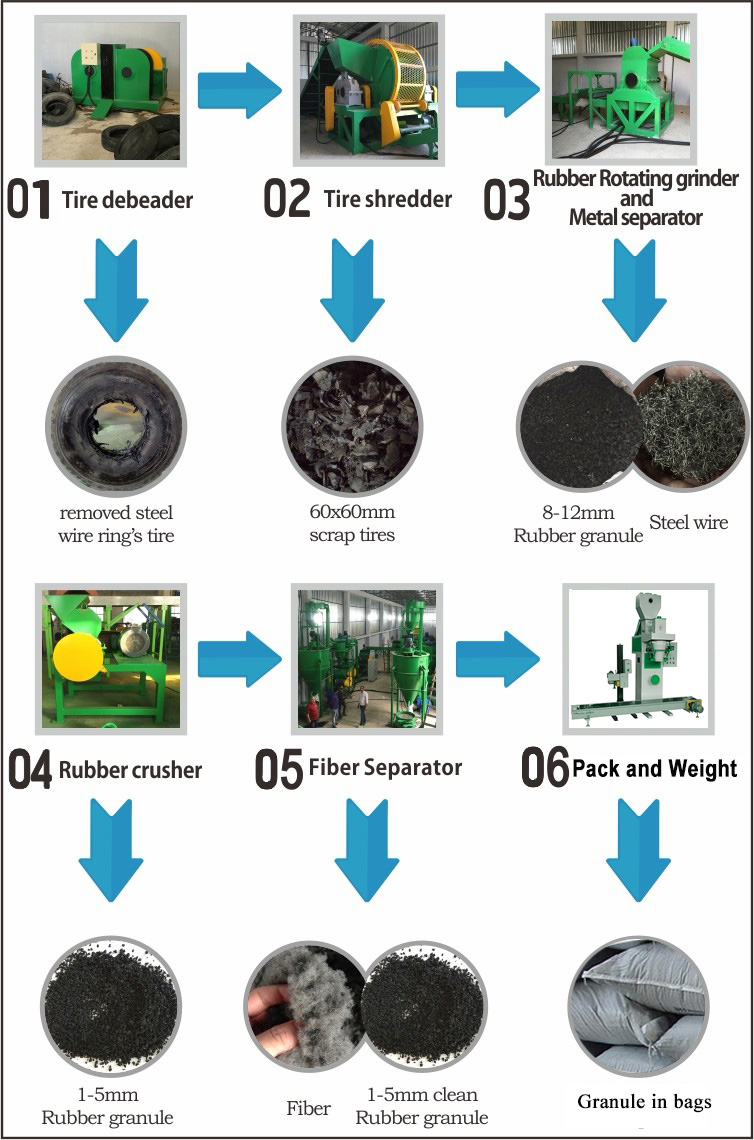

Flow chart of Tire Recycling Plant

Packing of Tyre Recycling Line

Successful Case

Company Overview

Sumac was established in 2011, specialized in tire rubber recycling and metal recycling industries. In 2015, SUMAC cooperated with ARS (Australia) to design and manufacture ELV recycling and dismantling equipments. We are committed to solving global recycling problem of end-of –life vehicles and wil

View More

Company Photos

Production Certification

Video

Send your inquiry to this supplier

Send Inquiry