1 / 1

Straw Alfalfa Palm Pellet Feed Making Machine

| Model No. : | Straw Alfalfa Palm Pellet Feed Making Machine |

|---|---|

| Brand Name : | HEXIE |

| Type : | Pellet Mill |

Xinxiang, Henan, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Product description

Ruminant feed definition

Ruminant feed: ruminant feed includes feed for ruminants such as cattle, raises, and camels. Ruminating means that after a period of time, the food that is half-digested in the stomach is returned to the mouth and chewed again. The ruminant is an animal that has a way of digesting this kind of digestion. The ruminant feed is divided into concentrate and fully mixed diet.

raw material

The raw materials of ruminant feed mainly include: corn, wheat, barley, soybean meal and other grain raw materials (similar to livestock and poultry feed), and also contain raw materials such as grass, hay and straw.

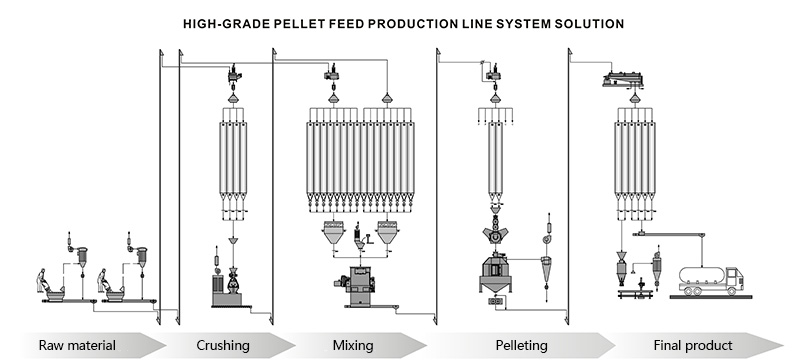

Ruminant Feed Production Line process flow introduction:

The ruminant feed is characterized by coarse pulverization (screen size 4-8mm), low curing and quenching requirements (the granulator uses a single layer conditioner), and the finished granules are large in diameter (particle diameter is about 4-10mm). The whole line is compact in design, reasonable in structure, meets environmental protection requirements, and can be oriented according to customer requirements.

Process diagram:

Raw material receiving and cleaning section, pulverizing section, batch mixing section, granulation section, Bagging Machine, auxiliary section.

Section introduction:

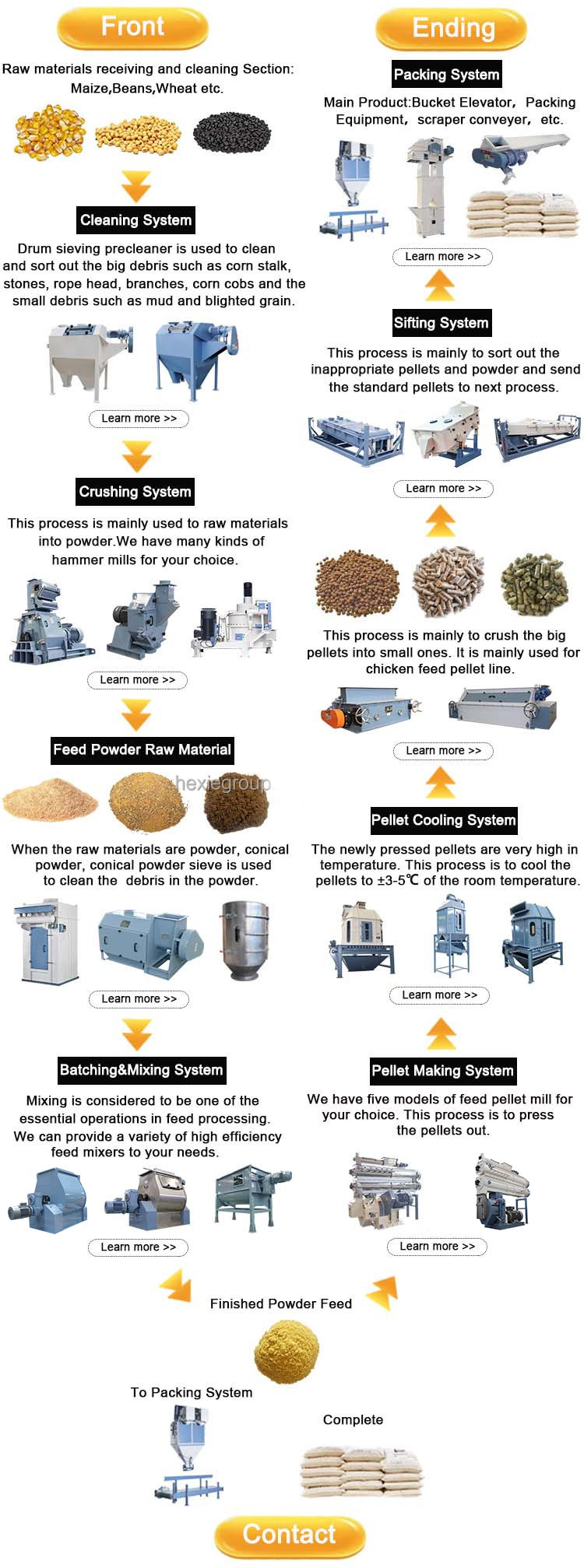

Raw material receiving and cleaning section: The function of cleaning is to clean the impurities in the raw materials, including large impurities, such as non-magnetic impurities such as ropes, clods, corn cobs and magnetic impurities such as iron nails, to ensure the quality of the products and the safety of the subsequent processing equipment.This section is divided into pellets for material cleaning and powder material cleaning.

Crushing section: Since the crushing fineness requirements of the ruminant feed are very thick, two small-power pulverizers are used in this section, and four pulverized silos are arranged above the pulverizer. Before the raw materials are put into the warehouse, the magnetic separator is used to remove impurities to ensure the safe operation of the crusher. The impurity-removed material enters the pulverization chamber for pulverization. The pulverized material is then transported by a screw conveyor into a bucket elevator and introduced into the batching bin through the distributor. In addition to the screw conveyor, the pulverized material is equipped with an auxiliary suction system, which not only saves energy, but also prevents dust from overflowing, lowers the temperature of the material and improves the pulverization efficiency.

Product Description

This Livestock Poultry Feed Plant have a complete feed production line can be used to make

feed pellets for all ages chicken. And it is a good choice for the farm owner and those who

plans to step into the poultry feed making industry.

Reasons:

1. they don't have enough experience in making poultry feed, but they have know enough

knowlege about how to raise chickens, which is more convincing when they sell the

pellets.

2. The capacity is not big, which can fulfill their requirement for their own farm use,

reducing the cost; and the capacity is not too small, take 10 hours working per day, the

output for one day is about 30 to 40 tons, which means at least in the 10 years, the

capacity of this Cattle Poultry Feed Plant can meet the requirement of the market;

3. The total invest for this Cattle Poultry Feed Plant is not big, which also reduces the

risk.

Animal Feed Production

Line :

1. Crushing

Section

When the thickness of the raw material is >5 mm, the raw materials must be used for size reduction before the feedstock is sent to the hammer mill (crusher) to reach a diameter of less than 3 mm.

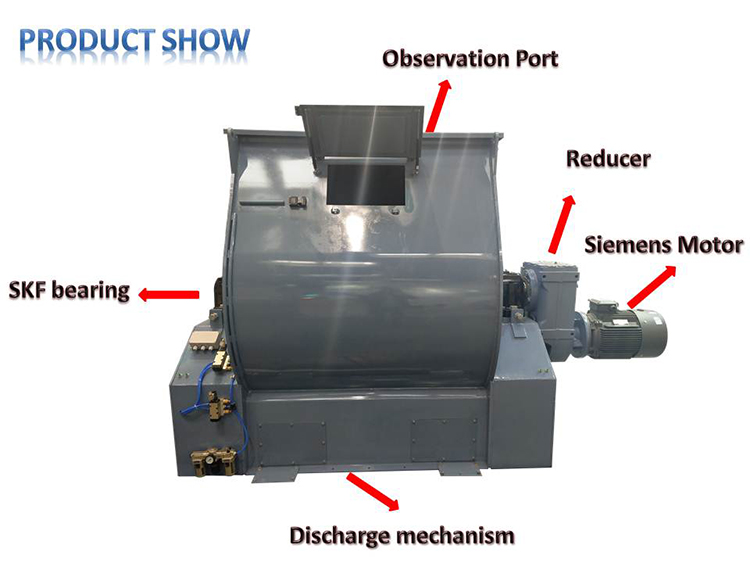

Two open doors structure, discharge rapidly, no leakage, no residue. Multiform liquid adding system and can be matched with compressed air jetting system Suitable for mixing premix, poultry feed, aquatic feed, additives and chemical and medicine industries, etc

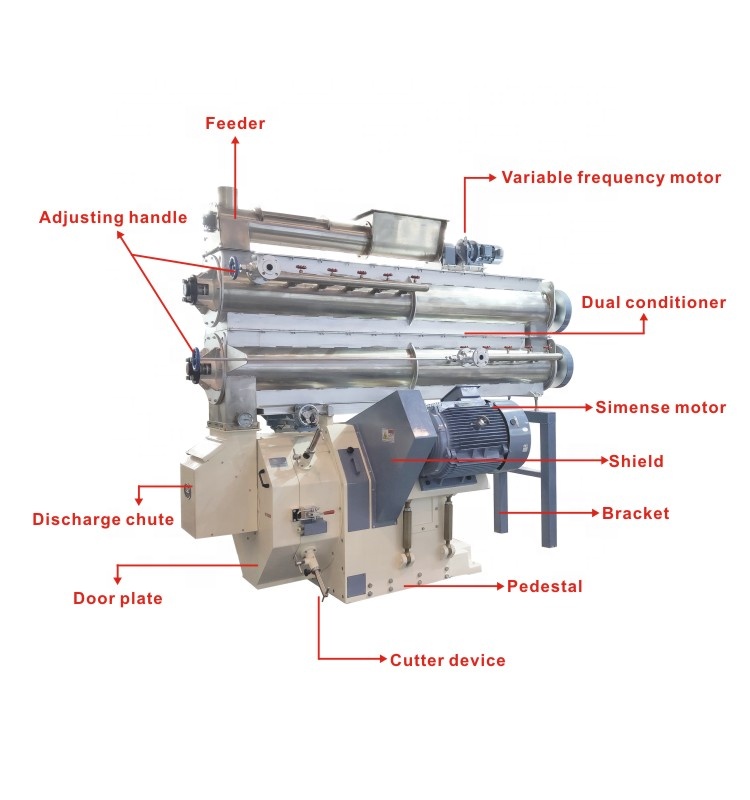

Acting as the heart part of the whole processing line, ring die pellet mill through adjusting the rotational speed of screw feeder axis to obtain the suitable flow of material, through the enforced feeder, enter the pressing room to pelletize finally.

After the pelletizing process, the temperature of the feed pellet is about 60-80 degrees Celsius, with a moisture content of about 15%. A Cooler must then be used to reduce the moisture content of the wood pellets to about 3-4%, thereby making the feed pellets easier to store.

5. Classifying screenIt is applicable for screening and classifying of mash or pellet feed. It is also can be used for cleaning of raw materials and classifyingof semi finished products after second grinding.

by large and medium feed mills.

6. Packing SectionAfter cooling and screening, the feed pellet must be protected from moisture and other environmental conditions. For this there is the packing process, which is effectively handled by our Semi-Auto Packing Machine.

FAQ

1. who are we?

Xinxiang Hexie Group was established in 1992, occupying a total area of approximately

100,000 square meters and it is a

diversified high-tech enterprise, engaged in research, production, sales and technical

service of feed machinery, breeding

equipment and veterinary preparations.

Its subsidiaries include Xinxiang Hexie Feed Machinery Manufacturing Co.,Ltd, Xinxiang

Hexie Smart Breeding Equipment Co.,Ltd and Xinxiang Hexie Animal Pharmacy Co.,Ltd. Hexie

Group provides a comprehensive, systematic and high-quality solutions for agriculture and

husbandry industry, trying to build a grand blueprint of [Harmonious world, world

Hexie".

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

Professional installation and after-sales service

3.what can you buy from us?

Hammer Mill,Mixer,Pellet Mill,Cooler,SIfter,Packing and other Feed Machinery.

Feed mill project,from 1tons~100tons.

4. why should you buy from us not from other suppliers?

1. 30 years experience 2. We are manufacturer.We have 500 workers,more than 30 engineers

and professional sales team 3. CE certafication , ISO9001:2008

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Currency:USD;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken:English,Chinese

Xinxiang Hexie Group was established in 1992, occupying a total area of approximately 100,000 square meters and it is a divers

Xinxiang, Henan, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier