Video

1 / 3

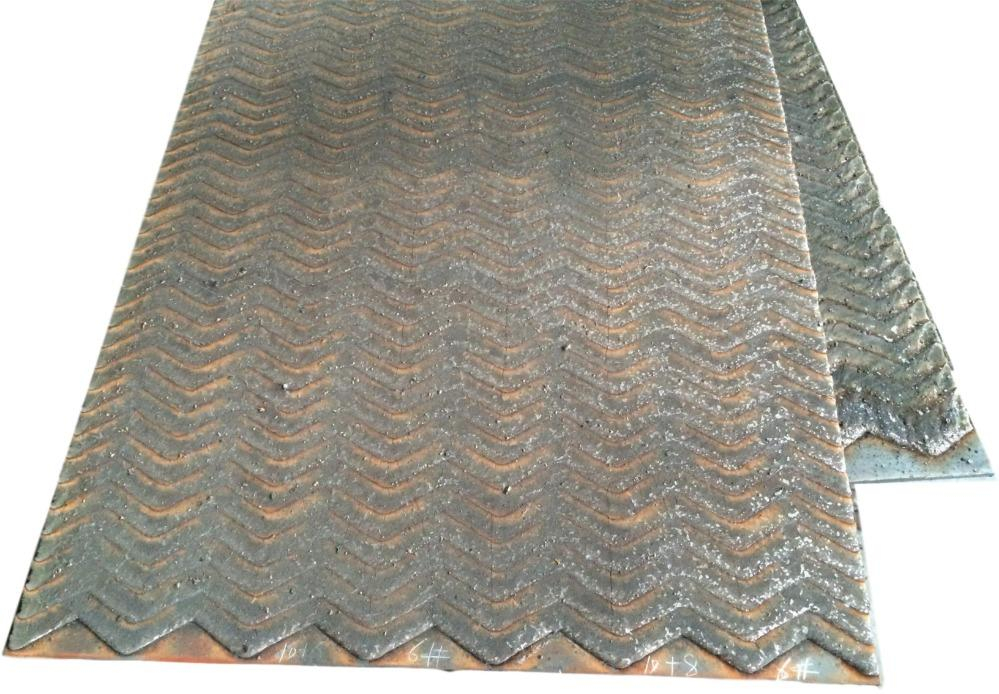

Smooth Hardfacing Wear Plate

thickness:

- 4~60mm

| Model No. : | HP-750P |

|---|---|

| Brand Name : | HP Plate, HP Welding |

| standard : | Astm,Din,Gb,Jis,Aisi,Bs |

Suzhou, Jiangsu, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

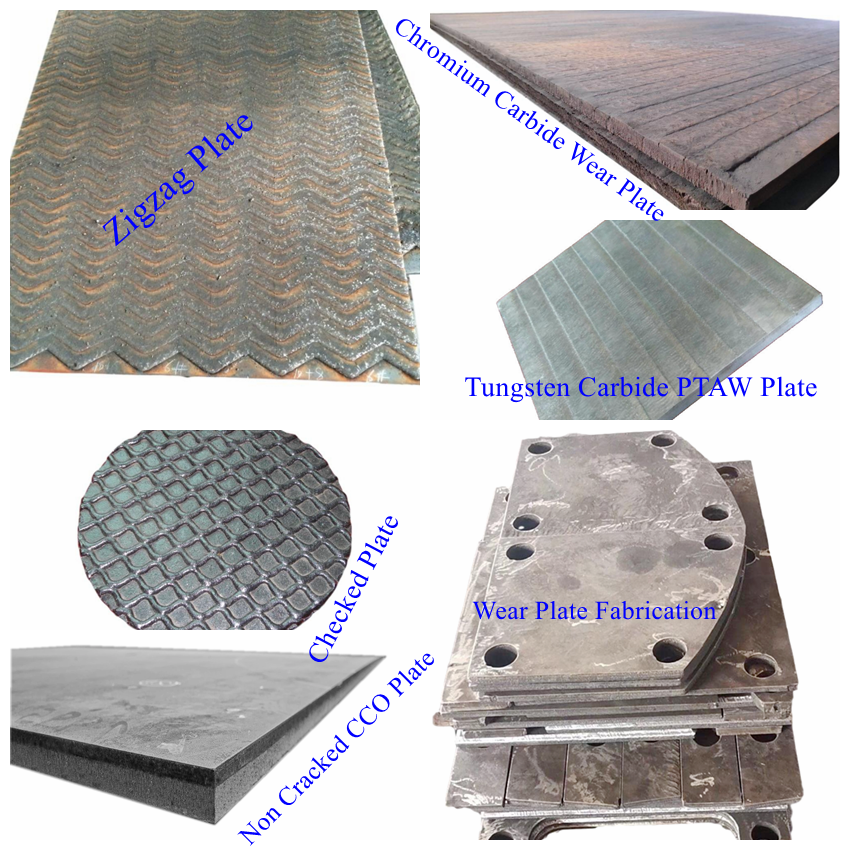

1. Product Name: HP Non Cracked Overlay Plate

2. Body Material: A36 Mild Steel + Chromium Carbide Overlay (Hardfacing)

3. Grade: HP750P (Smooth Hardfacing Wear Plate, Cement Vertial Mill Wear Plate, Composite Wear Plate)

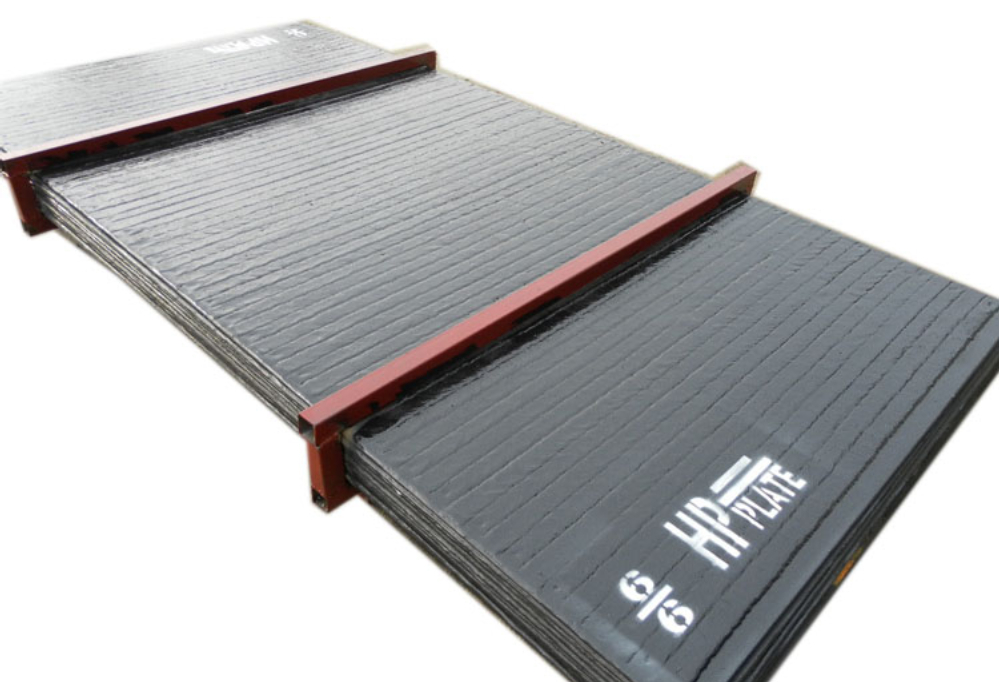

4. Standard Size: 1200*2400mm; 1000*3000mm or Customised

5. Quality Standard: ASTM G65, AISI, ASTM, BS, DIN, GB, JIS

6. Applications: Cement Industry, Steel Mill,Mining Site, Coal Mine

Chemical Industry, Power Generation & Others

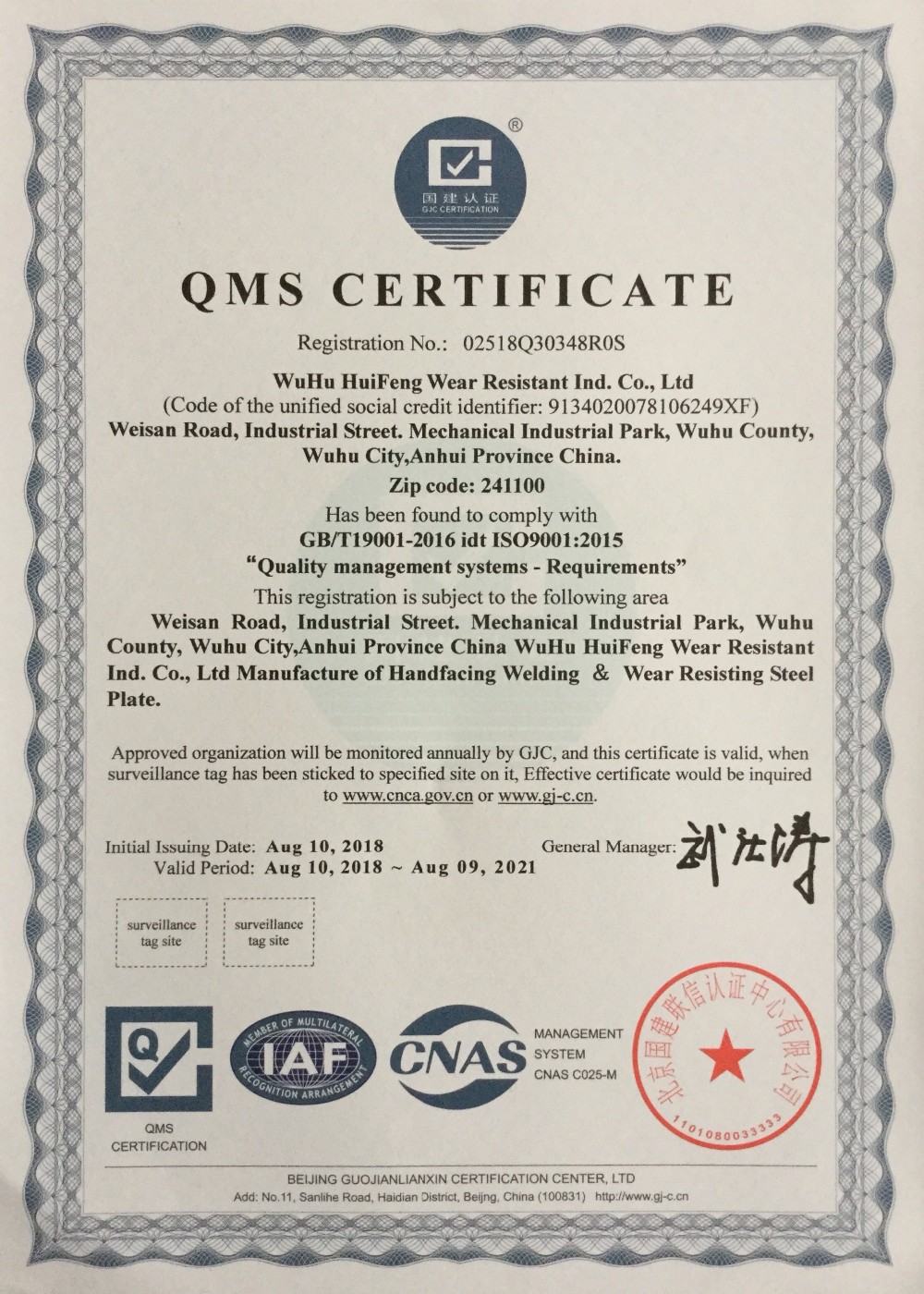

7. Certification: ISO9001, SGS, CTI, ROHS

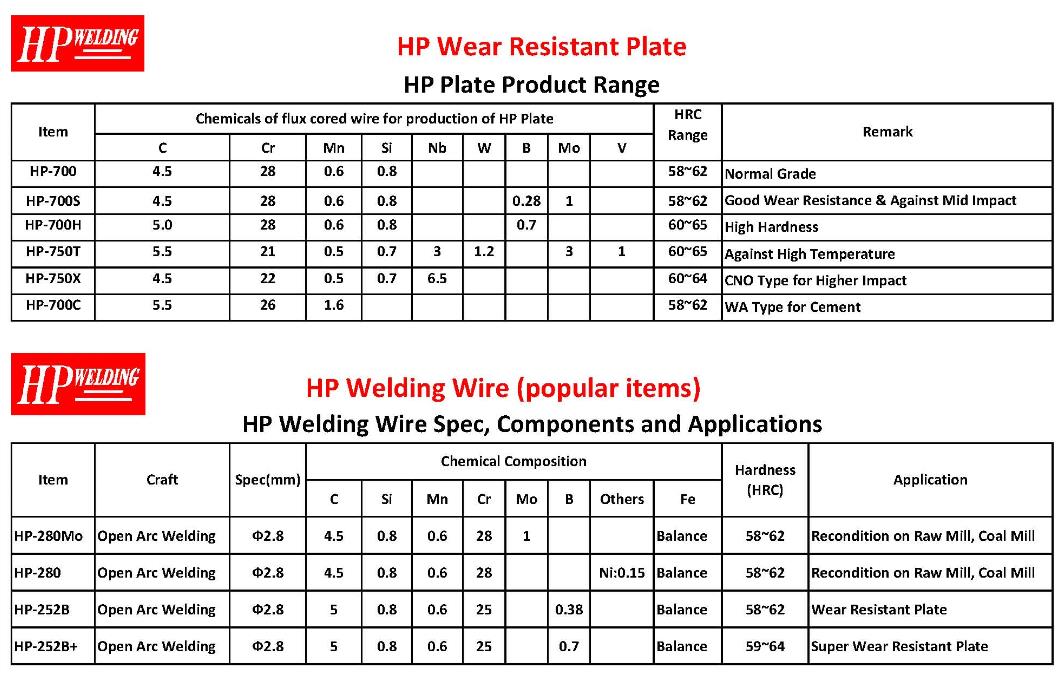

Standard Specifications of HP Wear Plate :

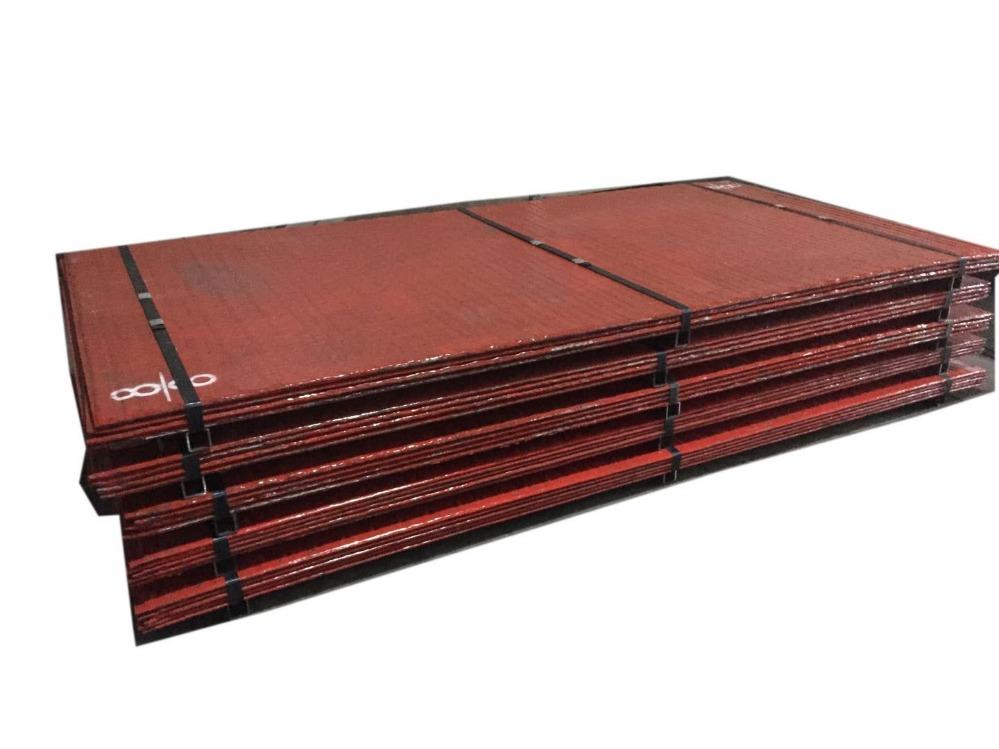

Packing & Delivery of Wear Plate

Packing Way: By Steel Tube, By Steel Belt, By Steel Pallet

Delivery Time: 20 days after order confirmation

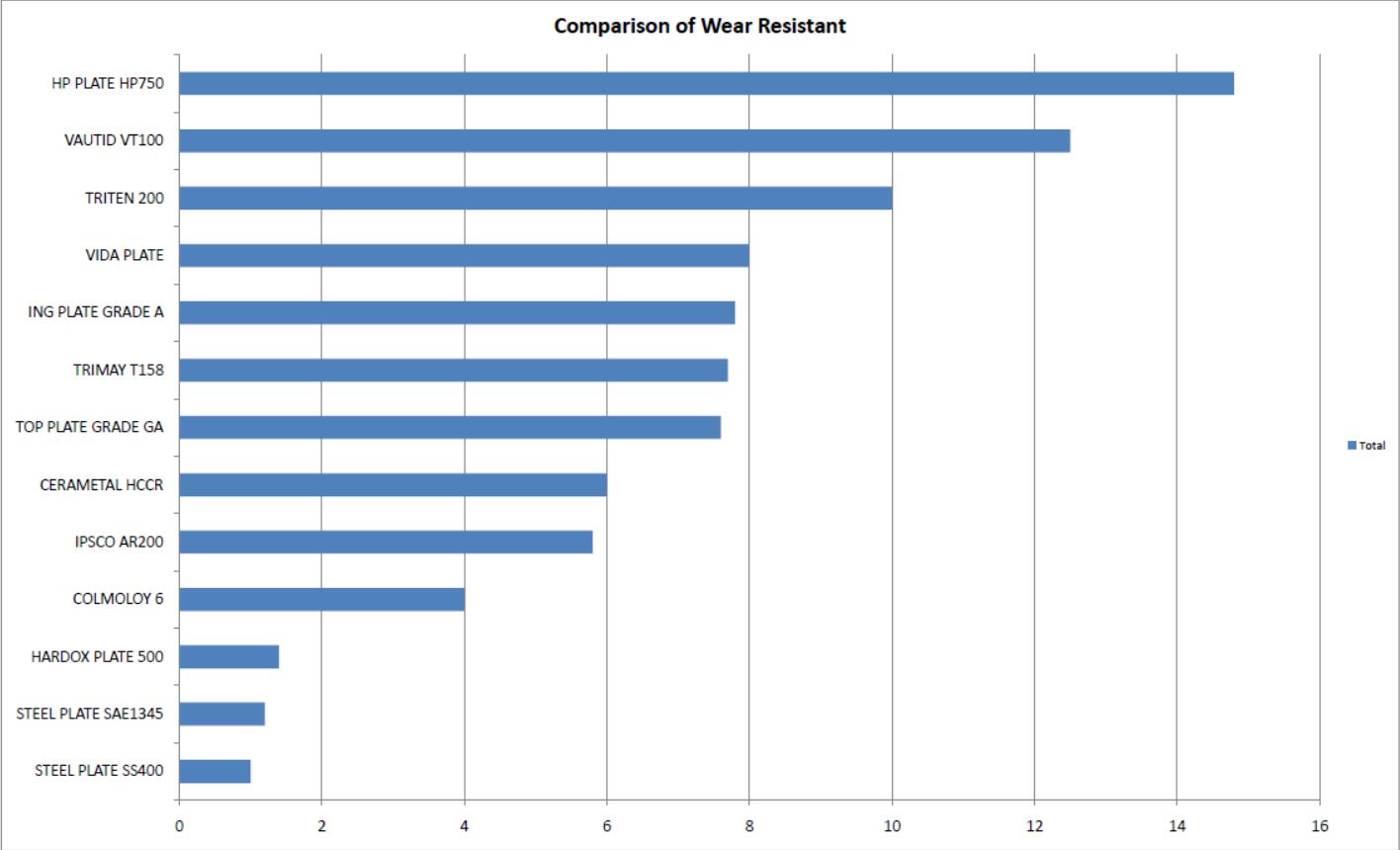

Anti-abrasion Comparison_HP Plate vs Other Plate

Company Information

HP Plate (Huifeng Wear Resistant Industry Co., Ltd.) was founded in 1994, as the former Taiwan's Upking-Kurimoto Ltd., led by president Mr. Zhang Kun-Mou, using the world-famous Japanese KURIMOTO hardfacing welding patented technology & welding materials produced by Vautid GmbH. HP Plate has become the most experienced expert specializing in production and sales of wear resistant products.

HP Wear Products Range:

HP Wear Product Applications

Cement Plant, Mining Site, Steel Mill, Power Generation, Glass Industry,

Dredging, Surgar Industy, Quarry, Construction, etc...where need to be anti-abrasion.

HP Factory Laboratory

Company ISO Certificates:

FAQ On HP Wear Products

Question: Can I cut or drill a hole in an HP overlay plate?

Answer: No. The chromium-carbide layer is not drillable or machineable. When necessary, you may be able to cut it with plasma, waterjet, or arc-gouging.

Question: What are the most popular applications with hardfacing products?

Answer: The typical applications include Mining Site, Steel Mill, Cement Industry, Power Generation, Glass Industry, Construction, Dredging, Oilsand, etc where need to fight with abrasion and impact.

Video

Suzhou, Jiangsu, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier