1 / 6

small automatic spray painting machine with drying function

$9800.00

≥1 Set/Sets

$8500.00

≥2 Set/Sets

| Model No. : | HYJ-B-0107 |

|---|---|

| Brand Name : | HENGYIJIA |

| Type : | Electrostatic Spraying Equipment |

Shenzhen, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- The Belt And Road

- Video

Product description

small automatic spray painting machine with drying function

| Item | Project parts | quantity | unit |

| A. | Customized 3.5m surround spray painting machine | 1 | Unit |

| 1. | Conveyor line body | ||

| a. | Line speed: 2-8m/min | ||

| b. | Designed speed 3m/min; | ||

| c. | Conveyor machine: table type conveyor | ||

| d. | Chainlink model: double wheel large roller type conveyor chainlink; | ||

| e. | Machine structure: SS 41-50 ×50 iron square and L40×40×3 Angle iron; | ||

| f. | Table: SPG-1.5t galvanized sheet | ||

| g. | Shield: SUS-201-1.0t stainless steel plate; | ||

| h. | Track and edge guard: made of 50*25 stainless steel flat pass | ||

| I. | Sealing plate :1.2mm cold plate made with powder surface finish. | ||

| 2, | Conveyor drive | 1 | Set |

| a. | The power is 1HP gear reduction motor, 120#1/60 reducer; | ||

| b. | Sprocket: 45# steel, tooth surface heat treatment; | ||

| c. | Rotary shaft: 45# steel machine processing; | ||

| d. | Shaft seat: 10mm thickness steel plate. | ||

| 3, | Rotary device of jig | 3 | Set |

| a. | Shaped table: friction rotating table; | ||

| b. | Power: 200W 1:20 gear reducer motor 1Set; | ||

| c. | Speed adjustment: 0.5HP inverter; | ||

| d. | Driving wheel: 3" pulley; | ||

| e. | Ensioning wheel: A3 steel machining production; | ||

| f. | Transmission belt: high quality anti-skid triangle belt. | ||

| 4, | Primary Jig | 80 | Set |

| a. | Bottom cover: round cover made of aluminum, knurled outside, precision bearing embedded inside; | ||

| b. | Pole: φ12 light circle, A3 steel, galvanized surface; | ||

| c. | Jig spacing: 100mm for one piece; | ||

| 5, | Automatic painting and control system (for 8 spray guns control) | 1 | Set |

| a. | Automatic spray gun: iwata wa-101, caliber :1.3mm | 6 | Pcs |

| Paint supply pump: model 716 1-bracket 8 pump; | 1 | Set | |

| c. | Pneumatic agitator: 5 gallon lengthened type; | 1 | Set |

| d. | Automatic static dust removal (1- 2) | 1 | Unit |

| 6, | Spray gun support group | ||

| H500mm | 1 | Set | |

| a. | Support is made of 40*40 nano plate with diameter of 20; | ||

| b. | “7” word type screw fixed, high and low, front and back freely adjustable. |

| B. | Preheating oven | 1 | Unit |

| 1, | Specification ::l1.2m*W0.8m*H1.0m | ||

| a. | The shell is made of 1.2mm cold plate bent and its surface is powder coating | ||

| b. | The inner tank is made of 1.0mm stainless steel plate. | ||

| c. | The heating is controlled by far infrared quartz heating. | ||

| d. | Temperature is adjustable from room temperature to 60 degrees constant temperature adjustable; | ||

| e. | Electronic control: electrical components are domestic and international quality products, national standard cable distribution. |

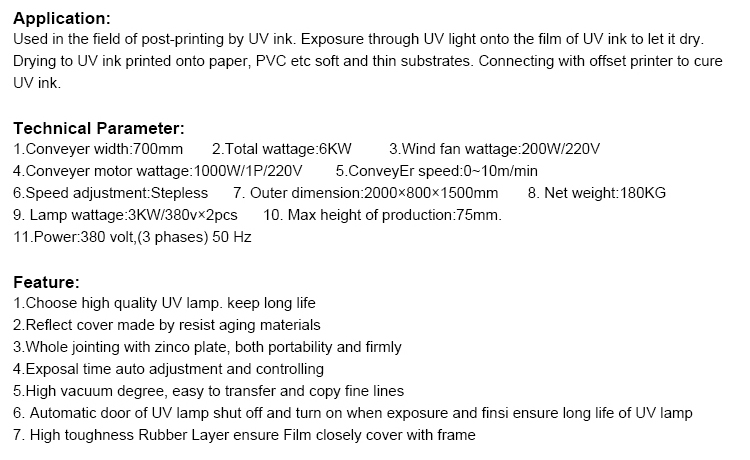

| C. | UV curing machine | ||

| 1, | UV curing oven | 1 | Unit |

| a. | Specification ::L1.2m*W0.8m*H1.0m | ||

| b. | Chassis: 40*40 square welding, surface painting treatment; | ||

| c. | The shell is made of 1.2mm cold plate bent and its surface is powder coating. | ||

| d. | The inner tank is made of 1.0mm stainless steel plate. | ||

| e. | One side of the oven body is provided with a louver air inlet, and the outlet is provided with black blocking light cloth; | ||

| f. | Light source: domestic 3KW-UV lamp 2Set, with transformer and capacitor; | ||

| g. | Lamp shade: it is made of 1.0mm stainless steel plate and is equipped with lamp shade | ||

| Stainless steel protective mesh to prevent products from falling onto the lamp tube; | |||

| h. | Automatic constant temperature control, automatically start the fan exhaust when the temperature is too high, | ||

| And has the fan delay stop function; | |||

| i. | Electronic control: electrical components are domestic and international quality products, national standard cable distribution. | ||

| 2, | UV rotation | 1 | Set |

| a. | Shaped table: friction rotating table; | ||

| b. | Power: 200W 1:20 gear reducer motor 1Set; | ||

| c. | Speed adjustment: 0.5HP inverter; | ||

| d. | Driving wheel: 3" pulley; | ||

| e. | Tensioning wheel: A3 steel machining production; | ||

| f. | Transmission belt: high quality anti-skid triangle belt. | ||

| 3, | UV exhaust fan | 1 | Set |

| a. | The fan is made of cf-1hp Jiuzhou Brand centrifugal fan. | ||

| b. | Mechanical damper is used for air volume regulation; | ||

| c. | The front end is equipped with high-temperature bellows hose, and the rear end exhaust pipe is the responsibility of the customer. | ||

| D. | Assembly costs | 1 | Unit |

| TOTAL POWER :10000W |

Q1. Can I have a sample order for plastic painting machine?

A: Yes, we welcome sample order to test and check quality.

Q2. What about the lead time?

A:Sample needs 7 days, mass production time needs 2-3 weeks for order quantity more than

Q3. Do you have any MOQ limit for coating machine order?

A: Low MOQ, 1set for sample checking is available

Q4. How do you ship the goods and how long does it take to arrive?

A: We usually ship by sea,

Q5. How to proceed an order for coating machine?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q6: Do you offer guarantee for the products?

A: Yes, we offer 1 years warranty to our products.

Q8: How to deal with the faulty?

A: Firstly, Our products are produced in strict quality control system and the defective rate will be less

than 0.2%.

Secondly, during the guarantee period, we will send new machine parts with new order for small quantity. For

defective batch products, we will repair them and resend them to you or we can discuss the solution i

ncluding re-call according to real situation.

Please contact us

Shenzhen, Guangdong, China

- Manufacturer

- OEM service

- Platform Certification

- SGS Certification

- Online Expo

- The Belt And Road

- Video

Send your inquiry to this supplier