1 / 1

Sinowon Advanced CE Certified Brinell Hardness Tester Instrument (SHB-3000C)

| Model No. : | SHB-3000C |

|---|

Product description

SHB-3000C selection of testing force and dwell time is controlled and monitored on the front panel, it is automatic during the process of loading, dwell and unloading.

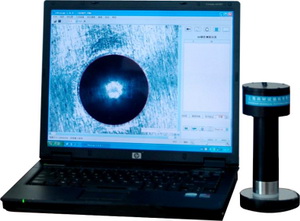

SHB-3000C adopts digital Brinell microscopes with adjustable LED illuminator, it doesn't need the operator to read the detail length of indentation, it only needs operator to aim the D1, D2 diagonal of indentation and press the length key twice above the Microscope, then the built-in computer can computer the Brinell scale and display the final testing result on LCD display automatically.

SHB-3000C supports the hardness conversion, it can use Brinell scale to get conversion scale of HRC, HRB, HRC, HV, etc.

Brinell Indenters

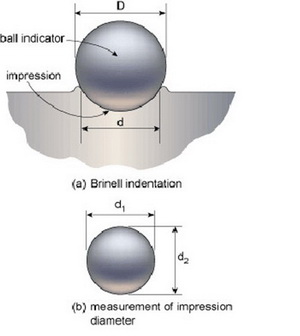

The Brinell hardness test method consists of indenting the test material with a 10 mm diameter hardened

carbide ball subjected to a load of 3000 kg. For softer materials the load can be reduced to 1500 kg or

500 kg to avoid excessive indentation.

The full load is normally applied for 10 to 15 seconds in the case of iron and steel and for at least 30

seconds in the case of other metals. The diameter of the indentation left in the test material is measured

with a low powered microscope. The Brinell harness number is calculated by dividing the load applied by

the surface area of the indentation.

The diameter of the impression is the average of two readings at right angles and the use of a Brinell hardness number table can simplify the determination of the Brinell hardness. A well structured Brinell hardness number reveals the test conditions, and looks like this, "75 HB 10/500/30" which means that a Brinell Hardness of 75 was obtained using a 10mm diameter hardened steel with a 500 kilogram load applied for a period of 30 seconds.

On tests of extremely hard metals a tungsten carbide ball is substituted for the steel ball. Compared to the other hardness test methods, the Brinell ball makes the deepest and widest indentation, so the test averages the hardness over a wider amount of material, which will more accurately account for multiple grain structures and any irregularities in the uniformity of the material. This method is the best for achieving the bulk or macro-hardness of a material, particularly those materials with heterogeneous structures.

When selecting a hardness tester for your application, it is important for you to consider the following:

A, Choose the correct test method based on the application.

Plan to use the highest test force and largest indenter possible. Consider the effects of the shape and dimensions of your test sample.

B, Verify the test results meet your requirements for accuracy and repeatability. There are significant differences between levels of performance within each classification of tester. A difficult job on one tester could be very simple and fast on another.

Answer these key questions:

1, What kind of hardness scale to be used?

2, What is the material to be tested, and is this material suitable to the type of test method you are considering?

3, How large is the part, component or specimen to be tested?

4, Is the test point difficult to reach?

5, What is the quantity of testing that will be done?

6, How accurate does your test result need to be?

7, What is your budget?

8, What is the required return on investment and do you have ways to measure reductions in costs- yields, throughput, operator efficiency?

9, What testing problems have you experienced in your current method?

10, How knowledgeable are the users of the tester?

| Product Name | Digital Brinell Hardness Tester | |

| Model | SHB-3000C | |

| Code# | 831-131 | |

| Testing Force | 62.5Kgf, 100Kgf, 125Kgf, 187.5Kgf, 250Kgf, | |

| 500Kgf, 750Kgf, 1000Kgf, 1500Kgf, 3000Kgf | ||

| 612.9N, 980N, 1226N, 1839N, 2452N, | ||

| 4900N, 7355N, 9800N, 14700N, 29400N | ||

| Testing Range | (8~650) HBW | |

| Hardness Display | LCD Display | |

| Magnification of Microscope | 20x Mechanic Microscope | |

| Max. Height Of Specimen | 225mm | |

| Instrument Throat | 135mm | |

| Output Data | RS 232/Printer | |

| Auto Hardness Conversion | HR, HV, HK, etc | |

| Power Supply | AC220V/50Hz;110V/60Hz | |

| Dimension(LxWxH) | 893 x720 x747mm | |

| Gross/Net Weight | 160Kg/130Kg | |

| Execution Standard | ISO 6506 , ASTM E10 – 12 , JIS Z2243 , GB/T 231 | |

| Accuracy of Brinell Hardness Testing | ||

| Hardness Range | Max. Tolerance | Repetition |

| HBW≤ 125 | ≤± 3.5 % | ≤ 3.5 % |

| 125 < HBW≤225 | ≤± 2.5 % | ≤ 3.0 % |

| HBW > 225 | ≤± 2.0 % | ≤ 2.5 % |

| Standard Delivery: | ||

| Code# | Standard Delivery | |

| 831-131 | Instrument Main Body | |

| 831-231 | 20x Digital Microscope | |

| 831-601 | Hardness Block HBW/3000/10 | |

| 831-611 | Hardness Block HBW/750/05 | |

| 831-411 | Ø10mm Ball Indenter | |

| 831-421 | Ø5mm Ball Indenter | |

| 831-431 | Ø2.5mm Ball Indenter | |

| 831-551 | Ø 200mm Flat Anvil | |

| 831-501 | Ø 60mm Flat Anvil | |

| 831-521 | Ø 55mm V-shape Anvil | |

| 831-801 | Power Cable | |

| 831-901 | Accessories Box | |

| 831-911 | Anti-dust Cover | |

| 831-831 | Mini-Printer | |

| SHB-3000C | Instrument Manual | |

Send your inquiry to this supplier