Video

1 / 6

Rice And Beans Automatic Baler Packing Machine

| Brand Name : | Durzerd |

|---|---|

| Types of : | Multi-Function Packaging Machine |

Product description

Rice And Beans Automatic Multi Balling Packing Line

Brief Introduction:

The rice and beans automatic baler packing machine also calling secondary bag in bag packaging machine, which is widely used for rice, beans, corns, seeds, sugar, salt at small bag from 500g to 5000g packing into big transparent plastic PE film bags, can packing in severals packing patterns, its the best way to do balling line, this Multi Baler Machine is synchronized with one or multi vertical form fill seal machine, to complete the packaged pouch products by request order form (one/two/three rows in horizontal) neatly into the baling bag, sealing and take out, capacity can reach maximun 130 samll bags into one big bag within one minute.

It achieves from bulk materials to be full automatic operation, saving labors, materials and financial inputs, improving the production efficiency and saving transportation costs with safety storage. The entire packaging line is usually equipped with Robot Palletizing System

Features:

This unit is mainly to complete the fully automatic packaging process of neatly loading the already packaged small bag products (500~1000g) into composite film plastic bags and heat sealing according to the requirements (form of arrangement: single or double-row horizontal grouping etc.) so as to realize fully automatic operation from small pack packaging of bulk material to packaging of composite film plastic bags, save input in manpower, material and financial resources, reduce production cost for customers as well as improve production efficiency. This unit is widely used for packaging of powdery and granular materials like rice, washing powder, salt, seeds, milk powder, etc. and is the first choice machine of many large companies for secondary packaging.

APPLICATION:

Detergent powder, rice, soy beans, sugar, salt, seeds, corn, peanut butter, chill, pasta, cookies, pet foods, etc. This machine can be customized as sugar baling machine and detergent powder packing machine.

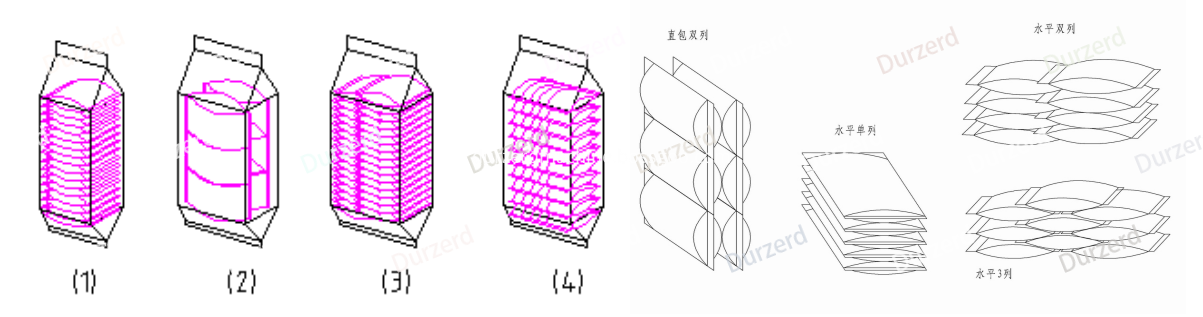

Sample bag type

Balling Packing Line description

Packing patterns:

Work Flow Chart:

Small pouch → horizontal conveyor → double-layer inclined conveyor → high-speed conveyor → counting and unscrambling machine → vertical bag-making packaging machine → Sealing → product output.

Technical Parameters

Model

Type of big bag

Packaging scope

grams

Packaging speed

bags/min

Form of arrangement

ZD920/1100/1500

Pillow bag,gusset bag(Formed by roll film)

150~5000 bagged products

4~8 for big bags

60~130 for small bags

Horizontal single or double-row grouping

ZD2-1

Prefabricated woven bag,Kraft bag,Paper-plastic bag,etc.

150~5000g bagged products

4~8for big bags

60~130 for small bags

Horizontal single or double-row grouping

Vertical Models Technical Parameters:

|

Model(Roll film width) |

920 |

1100 |

1500 |

|

Bag Length(mm) |

150~600 |

200~900 |

200-1000 |

|

Bag Width(mm) |

150~450 |

150~530 |

200~730 |

|

Max Width of Roll(mm) |

920 |

1100 |

1500 |

|

Packing Speed(bags/min) |

10~90 |

10-80 |

5-50 |

|

Air Consumption(Mpa) |

0.65 |

0.65 |

0.65 |

|

Gas Consumption(m3/min) |

0.5 |

0.5 |

0.5 |

|

Power Voltage (v) |

220v/380v |

220v/380v |

220v/380v |

|

Power (kw) |

5kw |

6kw |

6kw |

|

Weight(kg) |

1000 |

1100 |

1200 |

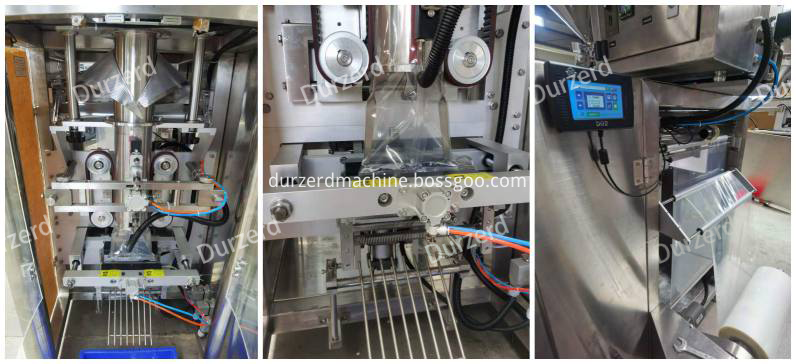

Details photos for vertical machine:

Our Service

Pre-sale Service

1. Equipment model selection;

2. According to the special requirements of customers, personalized customized products;

3. Train technicians for customers free of charge;

4. Free professional technical engineers to plan the site on site and design the best process and plan.

5. Acceptance of the product;

6. Assist the client in drafting the construction plan;

Medium-sales Services

Durzerd have the trained team to follow your orders methodically to guarantee the products can be finished on time with high quality.

After-sales Service

1.One Year Warranty,As long as there is a non-human fault in a year,free re-placement parts.

2.Parts Replacement,Don’t worry about the parts damaged or not sold after the machine is sold.we have a field factory with hundreds of enployees to serve you.

3.Engineer Asssignment,Lifelong maintentance,If your equipment breaks down,we will arrange engineers to repair it.

4.Online Instruction,We open online services,as long as your equipment failure,our engineers will be the first time for a one-to-one trou-bleshooting.

5.Feedback Survey,The engineer is required to bring a questionnaire to fill in the satisfaction with the engineer and the use of the equipment.

Video

Send your inquiry to this supplier