Video

1 / 4

PU Resin For Safety Shoe Sole Polyester Resin

Options:

- Sole A+C/B Mix ratio(By weight):100/69-71

- A/B temperatures (℃):40-50/40-50

- End of Rise Time (s):40-50

- Mold Temperature (℃):45-55

- Demold Time:3-5

| Model No. : | A-6170/B-8280 |

|---|---|

| Brand Name : | Xuchuan |

| place of origin : | China |

Suzhou, Jiangsu, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

PU Resin For Safety Shoes Materials

A-6170/B-8280

Shoe Sole Polyurethane Resins

|

Characteristic: high strength and cohesive force, good abrasion resistance |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Application: Double density sole system for common safety shoes and one-step forming casual shoes |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Typical properties of PU matrix

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Materials preheat A-6170: 50~60°C preheated at 50~60°C for 8~10 hours B-8280: 50~60°C preheated at 50~60°C for 8~12 hours |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Typical processing parameters & Reaction parameter

The adding content of water and hardener should be changed according to the reality Hardener 0~400g/18kg Mid-sole: H2O 50~55g/18kg Hardener 0~600g/18kg |

||||||||||||||||||||||||||||||||||||||||||||||||

|

Polyester Polyol Isocyanate Physical properties

|

||||||||||||||||||||||||||||||||||||||||||||||||

|

Demold time may be prolonged with the increase of sole thickness These physical data are acquired by testing a sample of 6mm thick.

|

||||||||||||||||||||||||||||||||||||||||||||||||

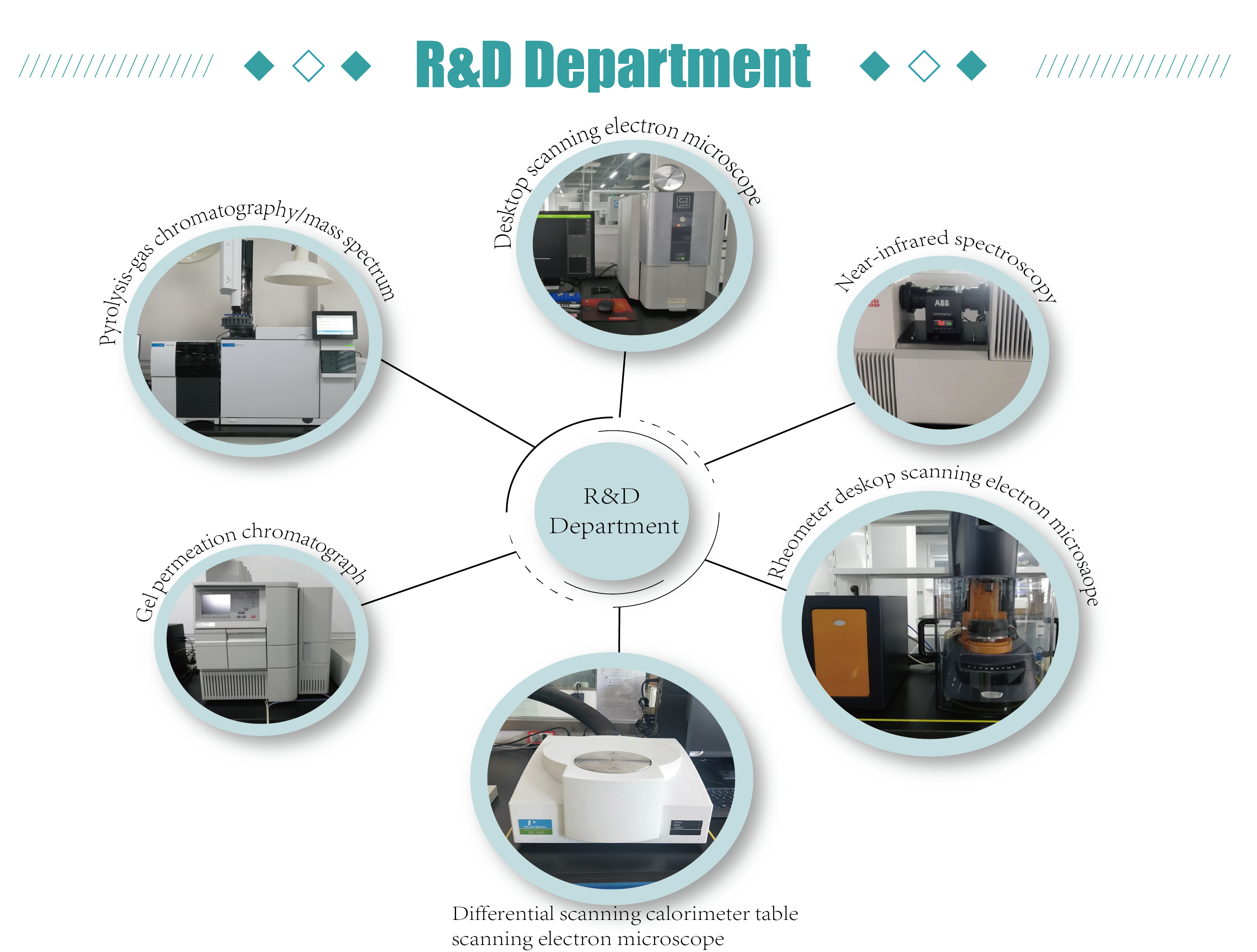

Xuchuan chemical established in 2007, company registered capital is RMB 500 million. The main products a

Video

Suzhou, Jiangsu, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier