Video

1 / 4

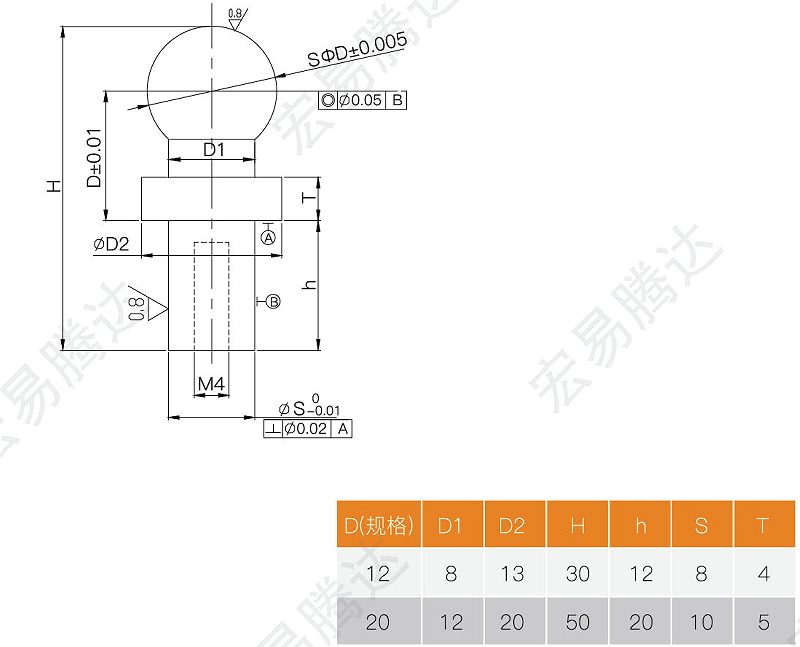

Precision Inch Tooling Balls

Options:

- HD-JZQ-D12

- HD-JZQ-D20

- Custom Ball Diameter

| Model No. : | HYTD-001 |

|---|---|

| Brand Name : | Hongyi Tengda and KTC Canada |

| place of origin : | China |

Suzhou, Jiangsu, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Product description

The Application of Tooling Balls

Introduction of Locating Balls:

Reference ball is a spherical tool for positioning and alignment, made of S136, heat treated to RC50-55 degrees, chromed plated , with eccentricity tolerance of ball to axis not exceeding 0.005mm. Below is a tool construction with reference shoulder. Precision tooling ball use as a reference point for critical inspection, layout and machining operations. The shoulder type down here has a precision height-reference shoulder to locate the ball in three dimensions.

The 2 pictures below from our 3D datas

Standard Metric Tooling Balls Sizes below

Custom Tooling Balls Sizes, , we also can make custom in sizes, such as inch tooling balls sizes custom , non standard precision tooling balls sizes custom.

Tooling Balls Assembly Set

1. Installation of tool reference balls on mold die parts

To achieve the correct installation of the tool reference ball on the mold part, a groove of 45X20X1mm is first machined on the non-forming surface of the mold part. Machining a ¢6H7 positioning hole on one side of the groove, the hole depth is 2-3mm deeper than the tool reference ball positioning column. The coordinate value of the tool reference ball center relative to the design reference value of the mold part is engraved in the groove.

2. Application of tool reference ball in CNC machining

The picture below is a part of a car lamp mold. The part is a special-shaped part, there is no reference number around, only at the bottom of the part calibration position. The CNC processing order of the parts is: 1, first roughing the front forming surface and finishing tool of the installation groove and installation hole of the reference ball, 2, and then the reverse rough, finishing around the bevel, 3, finally finishing the front. When machining the front, the center of the tool reference ball is used as the machining reference of the part. After modifying the parts, use the tool reference ball as the reference. If you do not use a tool reference ball, like this part, it is difficult to find alignment.

3. Application of tool reference ball in EDM processing

The following figure is the core of a car lamp mold. The core needs EDM processing in many places. The part is an irregular part. In processing, we use the tool reference ball as the processing reference of the parts, which is easier to find and take the number. It is difficult to process EDM without using a tool reference ball.

4. Application of tool reference ball in deep hole drilling

In the design of automobile mold, to ensure a good cooling effect, it is necessary to keep a certain distance between the water hole and the forming surface. The distance is small, it is easy to drill when drilling, mold leakage; The distance is too large to achieve the desired cooling effect. Therefore, the car mold, many water holes are inclined. It is very difficult to get coordinate values on the inclined plane when machining these inclined water holes on a common three-axis deep-hole drilling machine. If the deep hole drilling process oblique water hole, the use of tool reference ball can play a good positioning role, improve the processing efficiency and accuracy. As shown in the figure below.

Our company focuses on automotive checking fixture components for 15 years, we provide solutions of automotive fixtures components, such as checking pins, bushings, turning mechanism, go nogo gauges and pins

Video

Suzhou, Jiangsu, China

- Agent

- Distributor/Wholesaler

- Manufacturer

- Retailer

- Service

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier