Video

1 / 5

Powder Granules Fluid Bed Dryer Machinery

| Model No. : | FG |

|---|---|

| Brand Name : | Jirui |

| species : | Fluid Bed Drying Equipment |

Product description

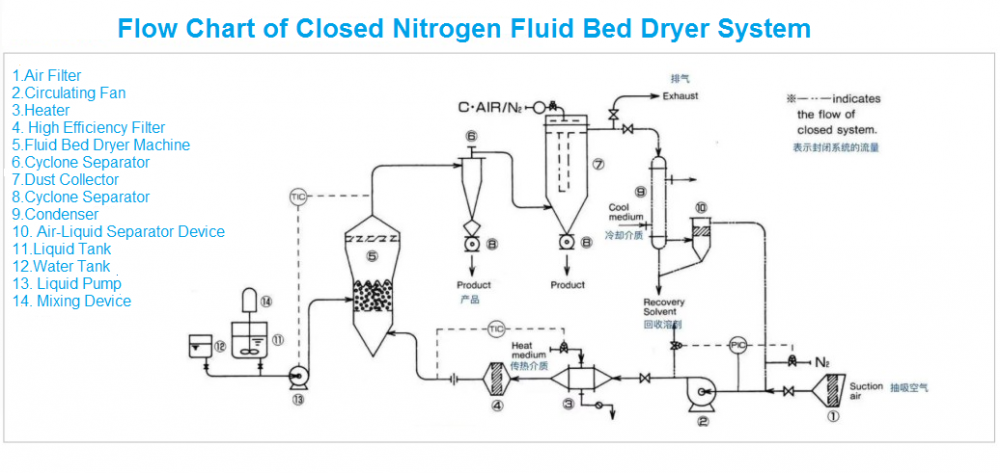

The Fluid Bed Dryer Machinery is also called fluidized bed dryer. It is widely used in the pharmaceutical, chemical and foodstuff industrials to reduce the moisture content of powder and granules. It has many features, such as reasonable structure, stable performance, convenient operation, no dead corners, and no exposed bolts. The drying machine adopts PLC automatic control. All operations are completed automatically according to the process parameters set by users. All process parameters can be printed and the original records are ture and reliable.

Principle:

The Fluid Bed Dryer Equipment is composed of the main machine, air handing system, heating system, control system, etc. When it works, the materials enter the silo of the boiling dryer. Set the procedures and parameters according to process requirements and the machine will start working. After filtered by the air handing system and heated by the heating system, the air enters the main machine. After the materials are fluidified and dried by hot air, the moisture is evaporated rapidly and the materials are dried instantly. After the operations are completed according to the set procedures and parameters, the material silo is pushed out and assembled onto the YTZ series fixed lifting material transferring machine for lifting discharging. or is pumped to a high position by the vacuum charging machine for granule sizing by the granule sizing machine, so as to effectively control dust pollution and cross contamination.

Drying time:

The drying time depends on various factors such as physical properties of material, moisture content, type of moisture ( free or inherent of water or crystallization) drying temperature etc. For example, the crystalline product can be dried faster than amorphous product containing same percentage of moisture at same temperature. Pharmaceutical granules & powder having approximately 20% to 25% moisture can be easily dried. Fluid bed dryers are normally supplied either with electric heating or with steam heating. However hot water/ hot oil circulation system can also be installed.

Technical Parameter:

|

Total Volume (L) |

12 |

22 |

100 |

220 |

420 |

670 |

1000 |

1500 |

|

Steam Consume (KG/Batch) |

12 |

23 |

70 |

140 |

211 |

282 |

366 |

465 |

|

Fan Power (KW) |

2.2 |

4 |

5.5 |

11 |

18.5 |

22 |

30 |

45 |

|

Mxing Powder (KW) |

0.55 |

0.75 |

1 |

1.5 |

2.2 |

2.2 |

3 |

3 |

|

Temperature (℃) |

Adjustable from ambient to 120℃ |

|||||||

|

Final Moisture Content(%) |

~0.2 |

|||||||

|

Noise (DB) |

≤75 |

|||||||

|

Recovery Rate(%) |

>99 |

|||||||

Video

Send your inquiry to this supplier