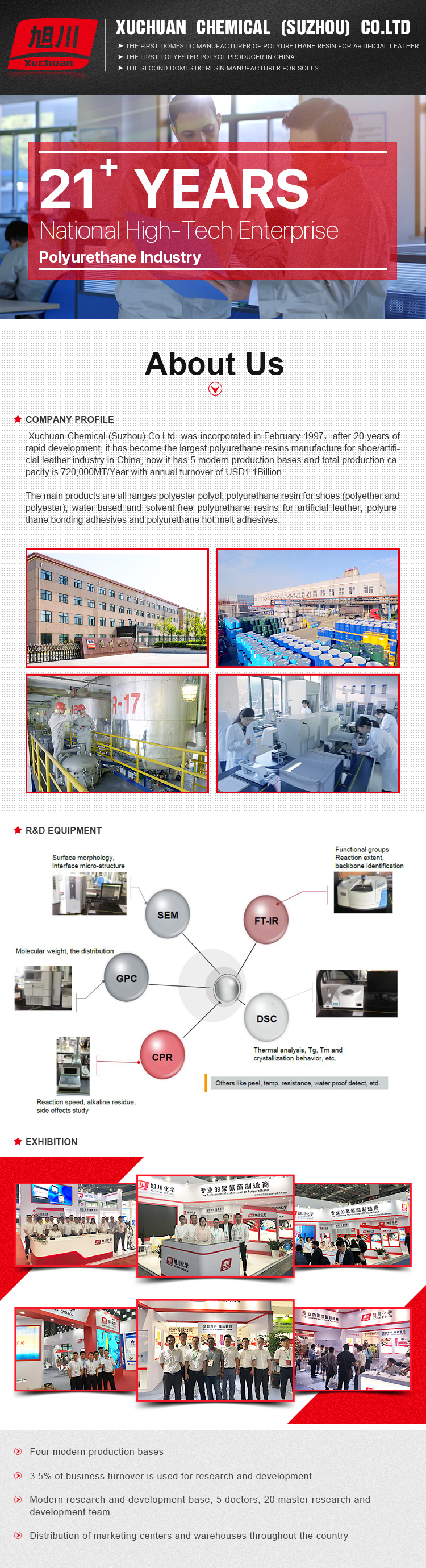

1 / 4

Polyester Prepolymer for Making Roller Wheel Screen Mesh

Options:

- Viscosity(mPa.s/85 ℃):1800-2000

- NCO% content:3.60-3.80

- Package(kg):20 / 200

- MOCA Level(%):10.8

- Pot Life(mins):10

| Model No. : | XCPU-E136 |

|---|---|

| Brand Name : | XUCHUAN |

| place of origin : | China |

Suzhou, Jiangsu, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Product description

PRODUCT DESCRIPTION

Cpu For Tyres Wheel

PU casting aluminium core for making cast iron pulley wheel

Custom Prepolymer For Wheel

Product Detail

| Viscosity(mPa.s/85 ℃) | 1800-2000 |

| NCO% content | 3.60-3.80 |

| Package(kg) | 20 / 200 |

| MOCA Level(%) | 10.8 |

| Recommended % Theory(%) | 95 |

| Prepolymer Temperature(℃) | 75-85 |

| Curative Temperature(℃) | 110-120 |

| Pot Life(mins) | 10 |

| Demould Time(@ 100°C (hrs)) | 1 |

| Post Cure Time(@ 100°C (hrs)) | 10 |

1,This product is a polyester polyol and toluene diisocyanate (T-100) in the synthesis of polyester polyurethane prepolymer.

2,Features: excellent wear resistance, oil resistance, mechanical properties.

3,Uses: Sieve, machinery parts, sealing ring, PU roller and other products.

4,Product Specifcation:

|

Name of products |

Appearances |

Viscosity(mPa.s/85 ℃) |

NCO% content |

Package(kg) |

|

XCPU-E136 |

solid |

1800-2000 |

3.60-3.80 |

20 / 200 |

5,Mixing and Curing Conditions:

|

MOCA Level |

Recommended |

Prepolymer |

Curative Temperature |

Pot Life |

Demould Time |

Post Cure Time |

|

% |

% |

℃ |

℃ |

mins |

@ 100°C(hrs) |

@ 100°C(hrs) |

|

10.8 |

95 |

75-85 |

110-120 |

10 |

1 |

10 |

6,Processing Procedure:

Prepolymer at 75 ~ 85 ℃ preheating, after vacuum degassing, the

melt MOCA good homogeneous mixing, deaeration, pouring, molding,

vulcanization molding, stripping, vulcanization.

7,Physical Properties:

Properties presented below are to be used as a guide and not intended

for specification purposes.

|

Hardness |

Tensile Strength |

100% Modulus |

300% Modulus |

Angle Tear Strength, |

Trouser Tear Strength |

Elongation |

Resilience |

DIN Abrasion |

Cured Specific |

|

Shore A |

MPa |

MPa |

MPa |

kN/m |

kN/m |

% |

% |

mm3 |

g/cm3 |

|

85 |

48 |

4.2 |

3.8 |

75 |

34 |

670 |

39 |

40 |

1.26 |

Pu Casting Gear Wheel

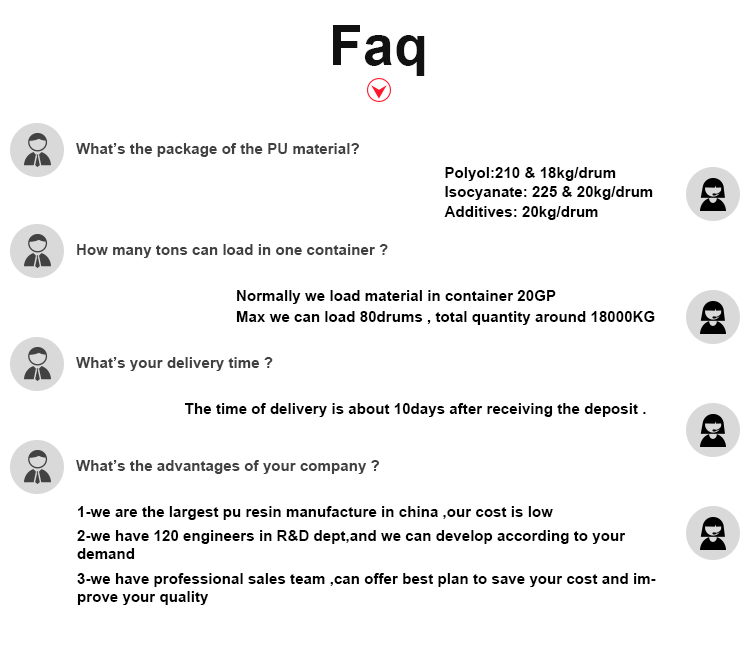

Precautions:

1, The product is easy to absorb moisture, will lead to product deterioration in the transportation, storage and use shall be kept sealed packaging good, original sealed storage for six months after opening, to be used up as quickly as possible to prevent moisture absorption metamorphism; If you can not run out of time, to be purged with nitrogen and sealed.

2, The information listed in this specification, may be due to product renewal and change, in view of processing technology, formulation and processing and other applications Not the same, pre-test their applicability in case of application of the product, please contact the

XUCHUAN chemical research and development or technical service department.

Suzhou, Jiangsu, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- Online Expo

Send your inquiry to this supplier