1 / 5

Ore Concentrating Machine, Centrifugal Machine

| Model No. : | STLB 20, STLB 30, STLB 60, STLB 80,STLB 100 |

|---|---|

| Brand Name : | Henghong |

| Type : | Gravity Separator |

Ganzhou, Jiangxi, China

- Manufacturer

- Service

- Trade Company

- OEM service

- Platform Certification

Product description

STLB Series Ore Concentrating Separator Machine

SUMMARY

STLB type Gold Ore Concentrating Machine is one kind of gold separating equipment, which is specially designed for the recovery of placer gold (alluvial gold ) and lode gold. It is an ideal gold recovery equipment - working on land or in river.

Our company has developed 5 types centrifuge. After test, the placer gold recovery rate is above 99%. For the gold rock mine, when the particle size is under 0.074mm, and the percentage is about 65%, the recovery rate is about 98%; when the material size is about 0.04mm, the recovery rate is about 97%.When the final concentration discharging cycle time is 1-4 hours for gold rock mine, and 4-8 hours for placer gold ore, the enrichment ratio is about 500-1000 times of raw material.

Technical parameter of Ore Concentrating Machine

|

TYPE |

STLB20 |

STLB30 |

STLB60 |

STLB80 |

STLB100 |

|

CAPACITY (T/h) |

0.2-1 |

2-8 |

10-40 |

35-70 |

75-120 |

|

PARTICLE SIZE (mm) |

0-3 |

0-4 |

0-6 |

0-6 |

0-6 |

|

FEEDING CONCENTRATION(%) |

0-50% |

0-50% |

0-50% |

0-50% |

0-50% |

|

BACKWASH WATER(T/h) |

1.5-2 |

4-6 |

10-15 |

17-25 |

40-60 |

|

OUTPUT (KG/TIMES) |

2-3 |

10-20 |

30-40 |

60-70 |

70-80 |

|

POWER (kw) |

0.75 |

1.5 |

4 |

15 |

18.5 |

|

REVOLUTION (r) |

800 |

600 |

460 |

400 |

360 |

|

PRESSURE WATER (Mpa) |

0.04 |

0.12 |

0.4 |

0.4 |

0.6 |

|

DIMENSION (mm) |

930*700*900 |

1180*1140*1250 |

1970*1670*1750 |

2300*1800*2200 |

2500*2000*2400 |

|

WEIGHT (kg) |

205 |

400 |

1300 |

1500 |

2000 |

REMARKS: THE STANDARDED MATERIAL FEEDING CONCENTRATION IS 30%~ 35%.

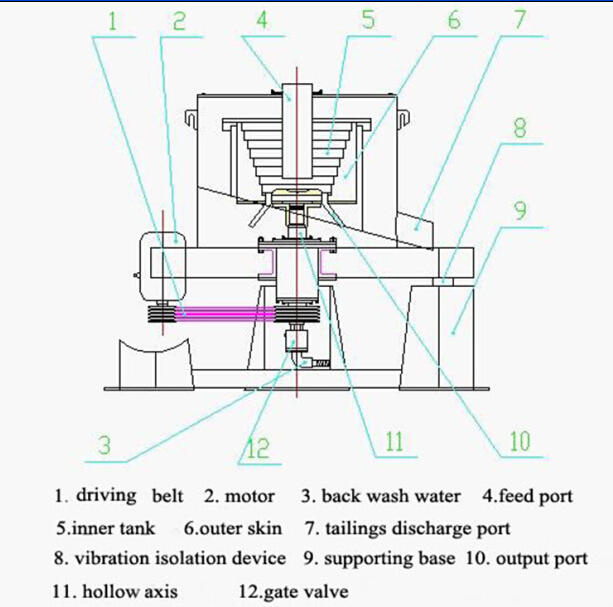

PRINCIPLE, STLB Ore Concentrating Machine Diagram as follow:

Motor (2) drive inner tank (5) rolling at high speed by belt (1) and axis (11) . Separation work will be strengthened in the tank (5) by centrifugal force. Light material will be discharged by port (7), and final refined ore will be output by port (7) after stopping work.

OPERATION

-The preparation and check before starting.

Check the motor before using according to instruction.

Check the machine foot margin, and see if be fixed

Check the driving belt if or not suitable or too tight.

Check the transmission parts if or not working well.

Check the output port if or not closed.

-Starting

After check, turn on the current and motors to see if the machine running direction same as required (please notice the marks printed on the machine). When all parts running normally, then start work.

Material and water feeding

Open the water back washing valve after machine running well, and meanwhile feed the ore pulp.

-Attentions in the operation

Keep watch on the temperature and current if work well.

Keep watch on the parts and see if work well.

Keep watch on the pulp and see if the concentration% is right.

Open the watching-cover after a period of time to see the enriched ore depositing situation.

-Stopping

On the condition of equipment running well, clean refined ore one time a day. Before stopping, stop feeding material at first, then stop running the machine. Open the output port (10), and wash the refined material into a tank (users provide it by themselves). The cleaning work takes about 10-20 minutes. After cleaning, then can running machine again for the next collection work.

-Equipment stop running unnormally

When equipment running unnormally, and need stop the machine, stop feeding first, then stop water back washing, then turn off the machine. The stopping time should be not too long, if not, ore in the tank (5) would be hardened. (If need stop in a long time, then need clear the refined ore first, then stop. ) When re-starting the running after a short time stop, feeding first, then back washing water to prevent the loss of gold.

MAINTENANCE

-Maintain regularly according to instruction

-Clean one time one shift

-Adjust the driving belt and tight the bolt

-Lubricating each shift (especially for the inner tank axis)

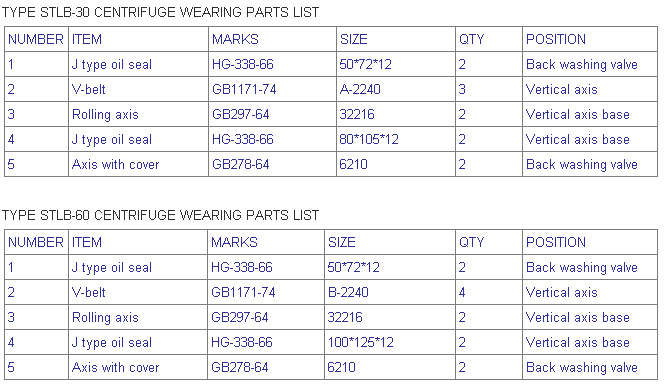

WEARING PARTS LIST

Water jacket Ore Concentrating Machine Pictures:

Packing and Delivery Pictures of Ore Concentrating Machine

Mine Site Pictures Of Ore Concentrating Machine

Gravity Separation and Flotation Separation Flow Chart For Reference:

Welcome to Visit our factory in your free time.

We are the professional machine manufacturer in China.

I need to ask you some details for sending you the more suitable quotation,

1.what is the raw material do you want to process?

2.what is the capacity per hour do you need?

3.what is the raw material input size?

4.what is the output size of your product?

Request for Quotation

Of course, free live-chat is available and you can get help immediately. Or you can send me email .

You can get the price list and we will contact you within one business day.

Mobile, WhatsApp, Wechat : +86 137 6772 2815

Ganzhou, Jiangxi, China

- Manufacturer

- Service

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier