1 / 1

New Lithium Iron Battery Recycling Plant

$100000.00

≥1 Set/Sets

$98000.00

≥2 Set/Sets

$95000.00

≥3 Set/Sets

Options:

- 500kg/h

- 1500kg/h

Send Inquiry

| Model No. : | sy-500 |

|---|---|

| Brand Name : | Suyuan |

| Name : | Lithium Battery Recycling Plant |

More

4yrs

Xinxiang, Henan, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Xinxiang Traceability Environmental Protection Equipment Co., Ltd.

You might also like

Product description

Lithium Iron Car Battery Recycling Machinery

Product Description

Fully Automated Waste Car Lead Acid Battery Recycling Machine Production Plant Cylindrical Lithium Ion Battery Recycling Plant, lithium battery of electric vehicle, positive electrode and negative electrode plate of waste lithium battery have certain value of recycling. Recycling these batteries can not only reduce the pollution of waste batteries to the environment, but also bring significant social and environmental benefits. In addition, the valuable components of waste lithium-ion batteries can be fully recycled and utilized, which brings huge economic benefits.

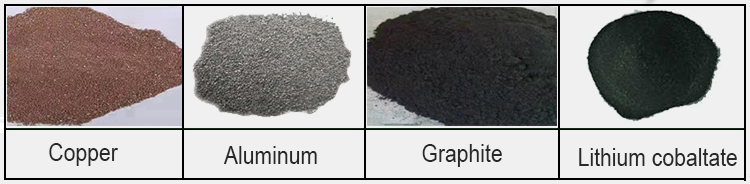

According to the structure of anode and cathode and the characteristics of component materials (copper, aluminum, cobalt powder,etc.), our company's waste lithium battery recycling plant adopts hammer vibration crushing, screening, air separation . The whole process is carried out in a sealed vacuum environment to ensure maximum recovery and no pollution. With the increase of electric vehicles and digital products, the recycling business of used lithium batteries will get better and better.

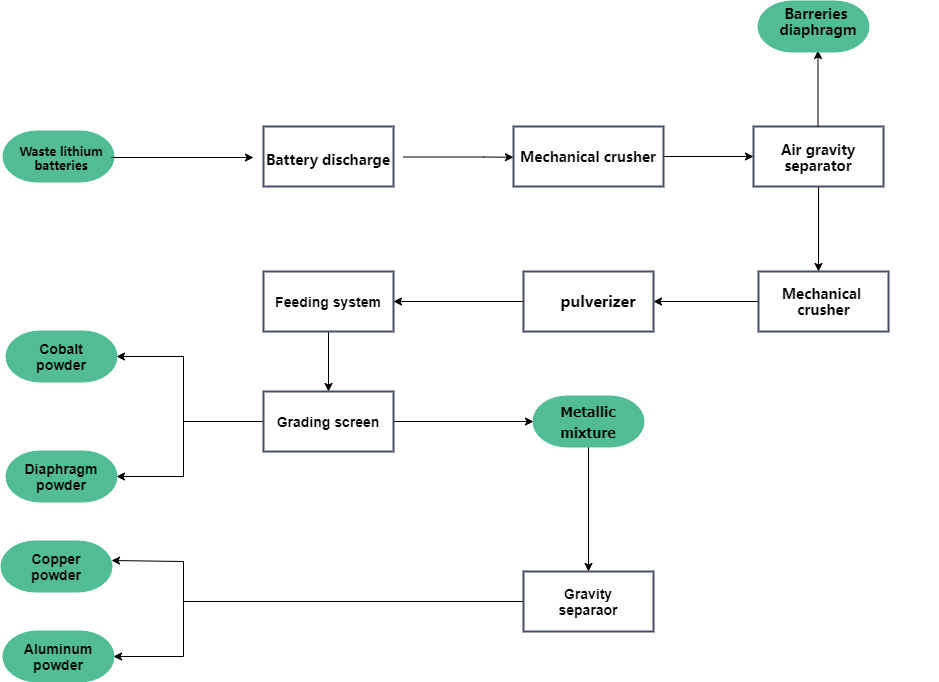

How does a lithium battery recycling plant work?

(1) Raw materials are crushed by the first crusher. (30 ~ 100 mm)

(2) By the sealing conveyor to the second crusher. (2 ~ 5 mm)

(3) The crushed material is transported into the air separator by high pressure air flow and separated into coarse powder, small powder and diaphragm. Small powder into the cyclone unloading device, coarse powder into the vibrating screen. (Air speed and pressure are precisely controlled by transducers)

(4) The material entering the rotary outflow material system is transported to the vibrating screen through the air duct, and the copper particles, aluminum particles, lithium cobalt powder and diaphragm powder separation.

(5) Coarse powder containing more metal, by high pressure air supply system transported to the vibrating screen, lithium cobalt mixed powder and copper/aluminum powder separated.

(6) The final separation system is our air gravity separator, which can completely separate lithium cobalt and copper and aluminum.

(7) The whole plant is operated under vacuum to avoid dust pollution and cobalt and lithium leakage.

(2) By the sealing conveyor to the second crusher. (2 ~ 5 mm)

(3) The crushed material is transported into the air separator by high pressure air flow and separated into coarse powder, small powder and diaphragm. Small powder into the cyclone unloading device, coarse powder into the vibrating screen. (Air speed and pressure are precisely controlled by transducers)

(4) The material entering the rotary outflow material system is transported to the vibrating screen through the air duct, and the copper particles, aluminum particles, lithium cobalt powder and diaphragm powder separation.

(5) Coarse powder containing more metal, by high pressure air supply system transported to the vibrating screen, lithium cobalt mixed powder and copper/aluminum powder separated.

(6) The final separation system is our air gravity separator, which can completely separate lithium cobalt and copper and aluminum.

(7) The whole plant is operated under vacuum to avoid dust pollution and cobalt and lithium leakage.

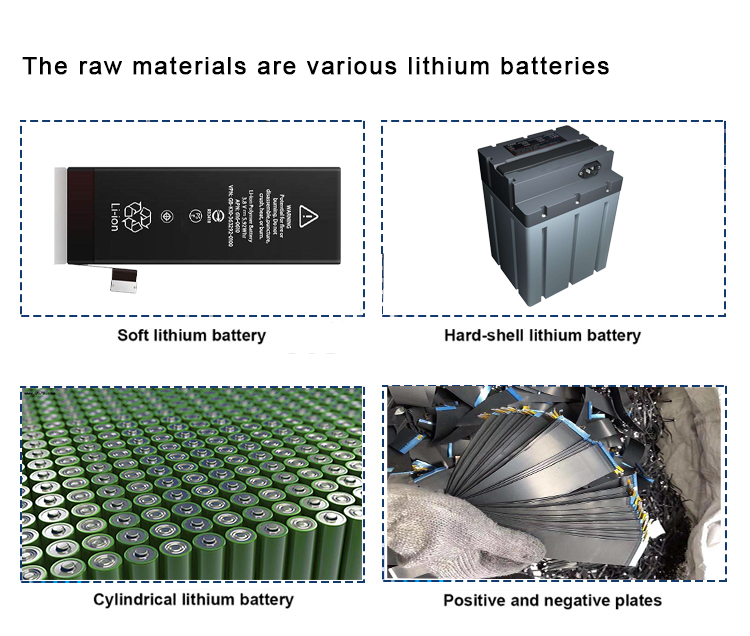

Raw material

We Can Turn " Waste" into "Wealth"

Different types of lithium batteries have different cycles. Different cycles. Please contact us for detailed configuration.

Features of equipment

1. The entire assembly line uses the PLC intelligent programming automatic control and man-machine interface touch screen, so that the even feeding of the entire production line and coordinated work can be realized.

2. Compact structure, reasonable layout, stable performance, noise reduction treatment of the crushing equipment.

3. The shredding, crushing processes are adopted for the broken part, and liquid nitrogen cooling is adopted for crushing.

2. Compact structure, reasonable layout, stable performance, noise reduction treatment of the crushing equipment.

3. The shredding, crushing processes are adopted for the broken part, and liquid nitrogen cooling is adopted for crushing.

4. Use the negative pressure feeding system and pulse dust removal system to purify the working environment.

5. The sorting part adopts the proportion sorting combined with the static careful selection, so that the metal recovery rate can reach up to more than 99%.

5. The sorting part adopts the proportion sorting combined with the static careful selection, so that the metal recovery rate can reach up to more than 99%.

Parameter

|

Model

|

Power (kw)

|

Recovery percent (%)

|

Collection coefficient (%)

|

Output (kg/h)

|

External dimension (mm)

|

Weight (kg)

|

|

SY-1000

|

450

|

98

|

99

|

150-200

|

15000*7500*4200

|

9250

|

|

SY-1500

|

680

|

98

|

99

|

200-300

|

17000*8200*4500

|

16500

|

|

SY-1800

|

1100

|

98

|

99

|

300-500

|

22000*11000*4800

|

18500

|

|

SY-2000

|

1980

|

98

|

99

|

1000-1200

|

25800*16000*5250

|

22500

|

Our Advantages

1. Easy-operated: The entire assembly line uses the PLC intelligent programming automatic control and man-machine interface touch screen, so that the even feeding of the entire production line and coordinated work can be realized.

2. Lower noise: We use noise reduction treatment of the crushing equipment to reduce the noise.

3. Clean without pollution: We Use the negative pressure feeding system and pulse dust removal system to purify the working environment.

4. High separating rate: The sorting part adopts the proportion sorting combined with the static careful selection, so that the metal recovery rate can reach up to more than 99%. (Our electrostatic sorting equipment is our most important product which has won a high reputation in the world.)

5. Lowest price with warmed service: we promise to provide high quality product with warmed service forever.

2. Lower noise: We use noise reduction treatment of the crushing equipment to reduce the noise.

3. Clean without pollution: We Use the negative pressure feeding system and pulse dust removal system to purify the working environment.

4. High separating rate: The sorting part adopts the proportion sorting combined with the static careful selection, so that the metal recovery rate can reach up to more than 99%. (Our electrostatic sorting equipment is our most important product which has won a high reputation in the world.)

5. Lowest price with warmed service: we promise to provide high quality product with warmed service forever.

Packaging & Shipping

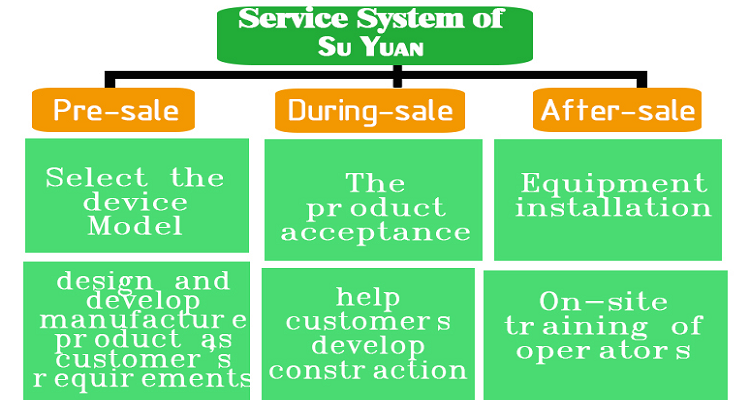

Our Service

1. We not only provide you machines but also offer the professional technical guidance and market evaluate.

2. We will provide all the machines for the complete production according to customer's requirements.

3. We will provide complete service for factory layout and other information to help customer to build the factory.

4. We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer.

2. We will provide all the machines for the complete production according to customer's requirements.

3. We will provide complete service for factory layout and other information to help customer to build the factory.

4. We will provide good service for machine installation and training, until the customers can run the machines and make stably production.

5. Except one year quality guarantee, we will provide after-sell service for all the life.

6. For long-term cooperation, we always provide good quality, good price and good service to customer.

Company Profile

OUR FACTORY:

Xinxiang Traceability Environmental Protection Equipment Co. Ltd. was established in the end of 2002.For more than 20 years, we have been committed to the research and manufacture of various waste resources separation and sorting recycling equipments.

The company has always adhered to the principle of “ Service First, Customer First ”. We will serve the new and old customers with high quality products and service. We will contribute to create a healthy and environmental world together !

The company has always adhered to the principle of “ Service First, Customer First ”. We will serve the new and old customers with high quality products and service. We will contribute to create a healthy and environmental world together !

Certifications

FAQ

Q: Why Choose Us?

1). Several Year's Experience

We have rich experience in equipment manufacturing. Our machines have high reputation both at home and abroad (Such as the Middle East, Southeast Asia, Africa and so on more than 10 countries and regions.)

2). Manufacturer, Not Dealer

Factory direct sale makes price more competitive.Customers are always welcome to visit our factory for machine test.

3). Fast Delivery:

We promise the goods can be shipped out on delivery date after confirmation of the order.

Q: How do I know the quality of your machine?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.

Q: When we only purchase one shredder machine production line, can we use it to shred other scrap materials like?

A: Yes, you can. It depends on the difference of blades teeth and quantity, which can be customized.

Q: Which brand of motor will you use?

A: We use domestic motor manufatured by Chinese-famous suppliers, but you can choose Siemens or other brand motor. Don't worry about our machine's quality.

Q: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer's requirement, we will dispatch engineers to guide installation and traning about the operation of the machine.

1). Several Year's Experience

We have rich experience in equipment manufacturing. Our machines have high reputation both at home and abroad (Such as the Middle East, Southeast Asia, Africa and so on more than 10 countries and regions.)

2). Manufacturer, Not Dealer

Factory direct sale makes price more competitive.Customers are always welcome to visit our factory for machine test.

3). Fast Delivery:

We promise the goods can be shipped out on delivery date after confirmation of the order.

Q: How do I know the quality of your machine?

A: You can send your sample scrap materials to us and we will test the machine for you without charging the fees. And we can send the machine test video to you. We also warmly welcome you to visit our factory to test our machine personally.

Q: When we only purchase one shredder machine production line, can we use it to shred other scrap materials like?

A: Yes, you can. It depends on the difference of blades teeth and quantity, which can be customized.

Q: Which brand of motor will you use?

A: We use domestic motor manufatured by Chinese-famous suppliers, but you can choose Siemens or other brand motor. Don't worry about our machine's quality.

Q: Will you dispatch the engineer to guide installation?

A: Yes, according to the customer's requirement, we will dispatch engineers to guide installation and traning about the operation of the machine.

4yrs

Xinxiang, Henan, China

- Manufacturer

- Trade Company

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

Send your inquiry to this supplier

Send Inquiry