1 / 4

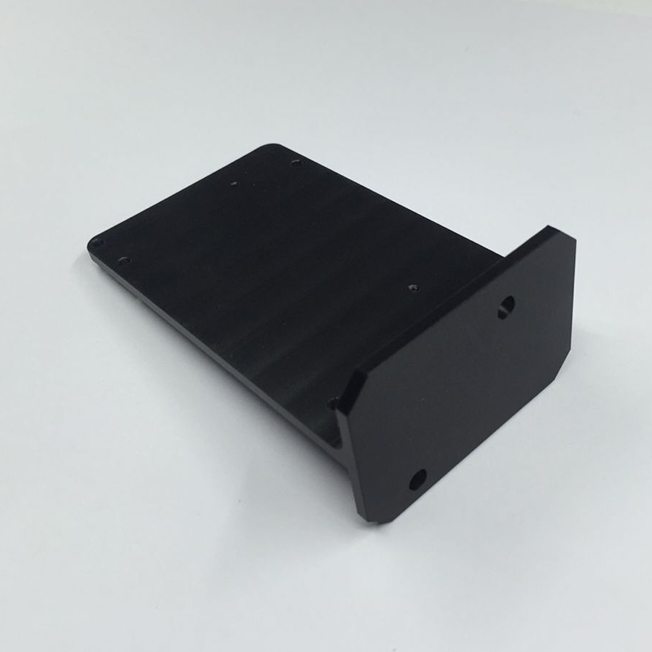

Machined Nylon Plastic Parts

| Model No. : | PL-061 |

|---|---|

| Material : | Nylon |

Shenzhen, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- The Belt And Road

Product description

Machined nylon parts widely replaces wear-resistant parts of mechanical equipment, take the place of copper and alloy as wear resistant parts of equipment. Machined nylon parts applies to wear resistant parts, transmission structures, household electrical appliances, automotive parts, wire rods machinery parts, chemical machinery parts, chemical equipment. Such as turbine, gear, bearing, impeller, crank, dashboard, drive shaft, blades, valves, screw, high pressure washers, screws, nuts, sealing ring, shuttle, sleeve, sleeve connector etc.. With the miniaturization of cars, the high performance of electronic and electrical equipment, and the acceleration of mechanical equipment lightweight, the demand for machined nylon parts will be higher and higher.

1 Material ( Machining Metal )

Machining Plastic :

Delrin (Black, White, Blue, Red, Yellow), Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, Peek, Acrylic, PMMA, PC, Polycarbonate, PAI, PPS, PA, PVDF, POM, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM.

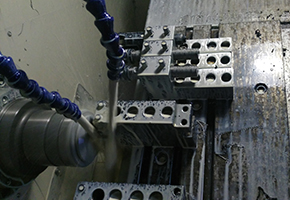

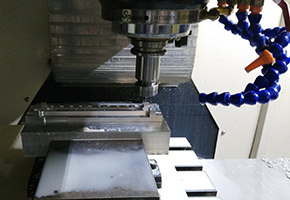

2 Our Factory Equipment Capabilities

- CNC Machinig Center, 3 Axis, 4 Axis.

- CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret.

- Milling Machine

- Grinding Machine

-

Drill Press

-

Tapping Center

-

Rotary Indexer

- Punch

3 Machining Processes

- CNC MillingCNC Turning

- CNC Milling

- CAM Programming

- sheet metal fabrication

- Grinding

- Cutting

- Thread Turning / Milling threading

- Tapping

- Drilling

- Knurling

4 Part Size ( CNC Milling and CNC Turning )

- CNC Milling Parts ( Max ) : Length 1030mm, Width 800mm, Height 750mm.

- CNC Turning Parts (Max ): Diamter 680mm, Length 750mm. The size of the above parts are machined in the workshop.

5 Tolerance:0.01mm. Minority size: 0.005mm. The measuring instrument can measure the dimension precision: 0.01mm.

6 Secondary Services of Machining Parts

-

Assemble

-

Plating Zinc Color ( Machining Steel parts )

- Anodize, Anodize color ( Black, Clear, Red, Blue,Yellow, Etc. ), Hard Anodize, Hard Anodize Teflon. ( Machining Aluminum )

- Electroless Nickel ( Machining Aluminum parts, Machining Stainless Steel parts, Machining brass parts )

- Passivation ( Machining Stainless Steel parts )

- Sand Blasting ( Machining Aluminum parts )

- Brushed ( Machining Aluminum parts , Machining Stainless Steel parts )

- Bluing and Blackening ( Machining Steel parts )

- Trivalent Chromium Process ( Machining Aluminum parts )

- Welding,brazing and soldering.

- Centerless Grinding and Burnishing

Shenzhen, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- The Belt And Road

Send your inquiry to this supplier