1 / 3

Insulating Glass Production Line with High-efficiency

| Model No. : | LBW2000PC |

|---|---|

| Brand Name : | WGM |

| Applicable industry : | Construction Works |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Product description

Product Description of Insulating Glass Production Line

6. Cleaning dryer and the water tank was made by stainless steel processing manufacture, transmits the roller for to bear the acid and alkali rubber roller, according to the glass thickness transmission roller spacing may the automatic control.

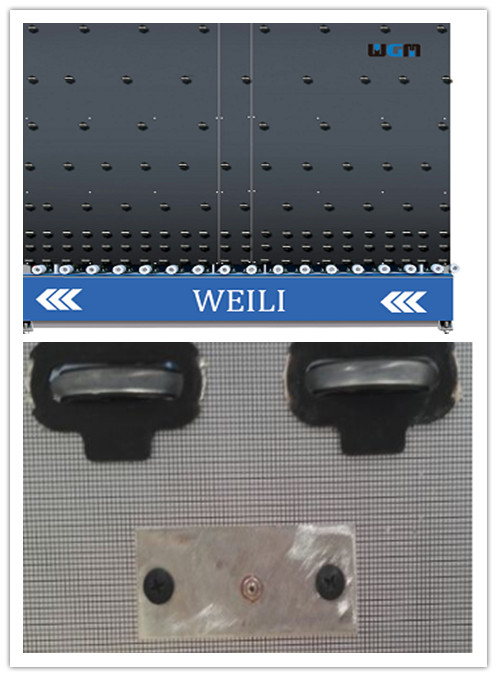

7. The press panel board of panel pressure board adopts to imported material, the press system and panel press system are controlled by the Servo motor , gear and rack press technology system, which guarantee the two pieces glass press together safely and steadily and the processing accuracy.

8. This Intelligent Insulating Glass Produce Line includes One lift, when you assemble a very big spacer bar on the glass, it's easier to use this lift to put it on to glass

Main technical parameter

|

Power Supply

|

380V 50 HZ 35KW

|

|

Dimension (L x W x H)

|

18800X2600X3050mm

|

|

Gas concentration

|

90%

|

|

Gas filling time

|

3-5s

|

|

Max glass size

|

2500x3050mm

|

|

Min glass size

|

300mmx400mm

|

|

Washing glass thickness

|

3-15mm

|

|

Washing glass speed

|

0-10m/min

|

|

Insulating glass thickness

|

48mm(can adjust)

|

|

Transmission glass speed

|

45m/min

|

|

Compress air

|

0.8m³/min

|

|

Air pressure

|

0.8Mpa

|

Main components :

|

NO.

|

Name

|

Brand

|

Brand Place

|

|

1

|

PLC

|

SCHNEIDER

|

FRANCE

|

|

2

|

10.0 inch touch screen

|

SCHNEIDER

|

FRANCE

|

|

3

|

Photoelectric switch

|

AUTONICS

|

KOREA

|

|

4

|

Limit switch

|

AUTONICS

|

KOREA

|

|

5

|

Transducer

|

SCHNEIDER

|

CHINA, FRANCE

|

|

6

|

Low voltage electric components

|

SCHNEIDER

|

FRANCE

|

|

7

|

Solenoid valve

|

AIRTAC

|

CHINA, TAIWAN

|

|

8

|

Cylinder

|

AIRTAC

|

CHINA, TAIWAN

|

|

9

|

Liner guide rail

|

PMI

|

CHIAN, TAIWAN

|

|

1

|

Bearing of cleaning section

|

SKF

|

SWEDEN

|

|

11

|

Servo motor

|

SIMENS / SCHNEIDER

|

GERMANY/ FRANCE

|

|

12

|

Transmission motor

|

DPG

|

CHINA

|

|

13

|

Triple

|

AIRTAC

|

CHINA, TAIWAN

|

|

14

|

Gas-type Filling

|

AIRTAC

|

CHINA, TAIWAN

|

|

15

|

Vacuum generator

|

SMC

|

JAPAN

|

Service:

| Pre- sale service | After - sale service |

|

* Inquiry and consulting support.

* Professional customize

* Visiting our factory.

* Provide factory layout according to your factory size in advance |

* Provide English Version of Installation/Operation/Service/Maintenance Manual.

* Online support

* Engineers available to service machinery overseas.

* Video technical support

* Field installation commissioning and training

* Field maintenance and repair service |

Package:

1.Machine packing with plywood pallet or according to customers` requirements

2.In plywood pallet and plastic film

3.In container

The normal package is plywood pallet and plastic film or pack it according to customers special requests.

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier