1 / 3

Ink and Printing Industry Solutions

| Model No. : | A200Ex |

|---|---|

| Brand Name : | Calstar |

| Brand : | Calstar |

Shenzhen, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Platform Certification

- The Belt And Road

- Video

Product description

Calstar provide Printing & Ink solvent solution with the solvent recycling equipment to not only reduce waste, but save money!

Did you know that on-site recycling could reduce your solvent purchases by as much as 95%, as well as dramatically reduce your hazardous waste?

Cleaning agent in the manufacture of Ink and Printing are very important.The detergent solvent recovery machine is used for painting production processing.

The Ink and Printing equipment uses a vacuum solvent distillation process that separates solvent into its components at lower-than-boiling point temperatures.

Any organic solvent waste residues are self contained within the unit. Distilled solvent can usually be sent down user and the reclaimed solvent is ready to go back on the press - and it's as good as new.

Any organic solvent waste residues are self contained within the unit. Distilled solvent can usually be sent down user and the reclaimed solvent is ready to go back on the press - and it's as good as new.

The Calstar solvent distillation unit is an off-press automated solvent recycling machine that, once installed, needs very little attention.

It has a small footprint and because it operates at low temperatures, its explosion-proof design is safe for installation and

Depending on the chemical to be recycled, Calstar`s team will Select the appropriate equipment to deal with recycling which will save money, time, and Energy saving and environmental protection

Calstar A200Ex Solvent Recycling Machine

A200Ex is manufactured according to Chinese explosion-proof standards (CNEX) and European standards (ATEX). By distillation and cooling, clean organic solvents are recycled for use.

After waiting a few hours, waste solvent has been reclaimed and you will get clean solvent to use!

Customer Benefits

●High quality solvent recovery: clear, pure, good performance;

●Low maintenance cost, easy to maintain;

●Easy operation and installation: recovery process and operation is simple, convenient. General staff can secure posts after short-term training;

●Short process time and short operation time;

●The equipment is compact, small and light, space saving;

●Less investment, pay back quickly on investment; well-preserved environment and high economic benefits with less investment.

Characteristic

●Explosion-proof electric equipment: in compliance with Chinese safety standards (CNEX) and European standards (ATEX), worry-free and safe for use;

●Self-developed standardized production, stable and durable quality assured, has good performance;

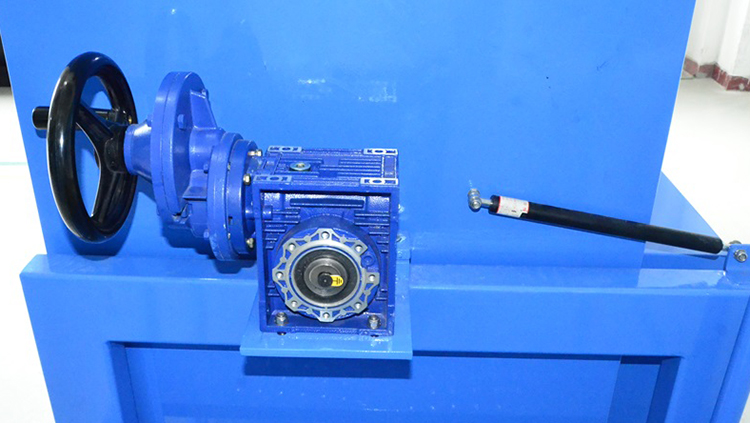

●Tilting-type: gradually tilt and pour out residue, easy to remove residues;

●High quality durable stainless steel tank, prevent chemical corrosion; two-tier structure, indirect heating, reinforcement barrelhead design, precise temperature control, explosion-proof, anti-leakage;

●Heating Method: heat medium (heat transfer oils) indirect heating;

●Digital heating temperature controller: advanced numerical performance, safety intuitive, accurate and convenient heating temperature control;

●Multiple operational safety protection functions: pre-set temperature shutdown function; timer shut off function; ultra-high temperature protection features; high-voltage protection function; power failure protection function.

Customizing & Auxiliary device:

※You are free to customize the equipment to meet your specific needs, or choose auxiliary device in compliance with your needs in order to achieve the desired treatment effect.

Technical Parameters:

(for reference, the data subject to change, please with your choice models the actual date).

|

Model |

Volume |

Ambient |

Heating |

Socket Power |

Dimension |

Weight |

|

A200Ex |

225L |

5~30°C |

50~190°C |

3Φ380ACV/50Hz |

2100*1130*1950mm |

629kg |

NOTE: Recovery time is under ideal conditions in laboratory test values during recovery of toluene for reference. The actual operation in the process of recovery and the waste solution inside the impurity content, high and low boiling point solvents, environmental temperature, viscosity, etc. differ.

Application Fields:

Calstar solvent recycling machines are applicable to reclaim most of common organic solvents. As long as you have a solvent recovery and treatment needs, recyclable processing industries in common organic solvents, no matter what kind of industry.

The equipments have been widely used in various industries at home and abroad.

1.Automobile manufacturing and repair industry:

vehicle spraying equipment and spray gun cleaning pipeline thin materials, such as: naphtha, toluene, xylene, methyl ethyl ketone, n-butyl, etc.; clean gasoline engine produced by such processes as solvents.

2.Electronic product manufacturing industry (e.g.: LCD, LED, etc.):

cleaning mold, cleaning of electronic products themselves cleaning agents, such as: ethanol, acetone, trichloroethylene, etc.

3.Precision instruments and hardware manufacturing industry:

cleaning mold and processed products, organic solvents, such as: naphtha, hydrocarbons, kerosene, gasoline and other solvents.

4.Sports Equipment Manufacturing:

manufacturing golf head, melting wax casting rods and other cleaning agents, spraying and cleaning clubs, fishing rod, etc. Solvent.

5.Shoes industry:

cleaning spray equipment, a variety of organic solvents, such as: shoe outsole, heel spraying, printing processing, cleaning shoe surfaces.

6.Plastic products:

cleaning mold and processed products, organic solvents, such as: cleaning solvents used in printing.

7.Printing industry:

machine wash plates with the cleaning agent, such as: plate washer solution, washing solution.

8.Paint Manufacturing Chemical industry:

cleaning of production equipment, containers and filling equipment, such as a variety of organic solvents and paint transfer agents, such as: naphtha, xylene, methyl ethyl ketone, butyl and so on.

9.FRP products industry:

surface anti-corrosion coating with beautiful production process used solvents, such as: yacht production, wind turbine blade production.

10.Colour decoration and gold & silver ornament:

surface pretreatment cleaning and plating pre-treatment used in solvents.

Shenzhen, Guangdong, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Platform Certification

- The Belt And Road

- Video

Send your inquiry to this supplier