1 / 1

[Hukay] Multi-Plate circular tct saw blade

Get Latest Price

Send Inquiry

| Model No. : | 255x2.8x1.8x30x36T |

|---|---|

| Brand Name : | Hukay |

Shijiazhuang Pioneer Tools Co., Ltd.

You might also like

Product description

Specifications 1. Multi saw blade

2 .Experience: 17 years

3. Steel plate: 75 Cr1

4 .Teeth: Ceratizit carbide tips

5 .Grinding: VOLLMER

[Hukay] Multi tool multi ripping saw blade Size: 255x2.8x1.8x30x36T Origin: Shijiazhuang, China. Features: 1. Ripping natural woods, along the grain.. 2. Tungsten Carbide from Ceratizit Luxembourg. 3. Saw body: 75Cr1. 4. Cooling slots in the saw body prevent excessive heat build-up. 5. Minimal feed effort is required resulting in less operator fatigue 6. Alternate top bevel tooth(ATB). 7. Used on multi-ripping saw, single or double sizing machine, profiling machine. Dimensions:

Saw blade making process from our factory:

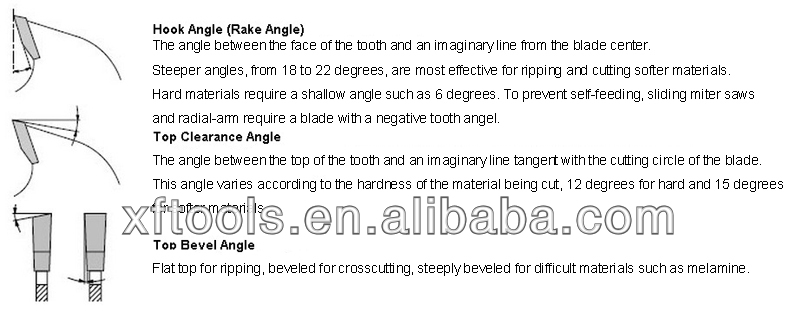

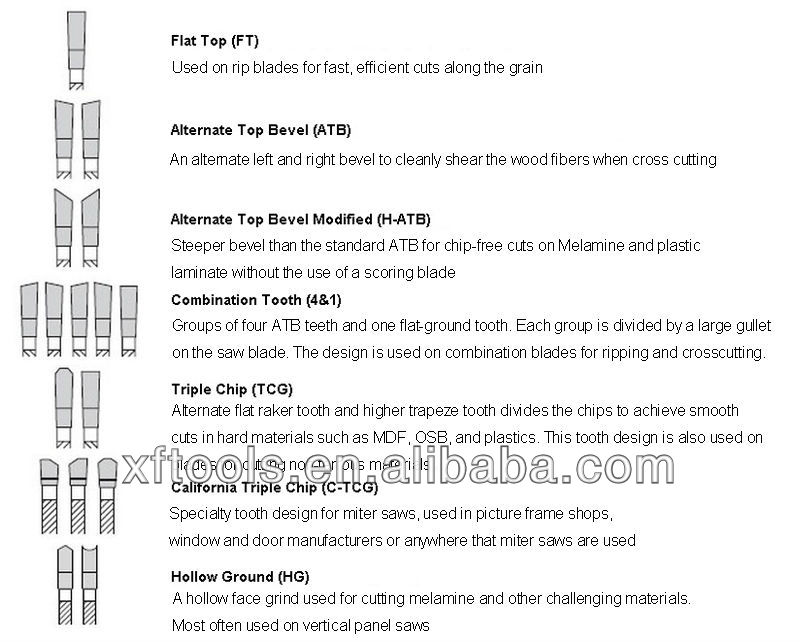

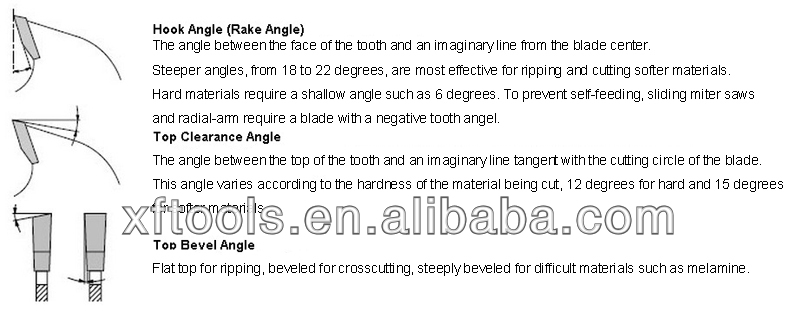

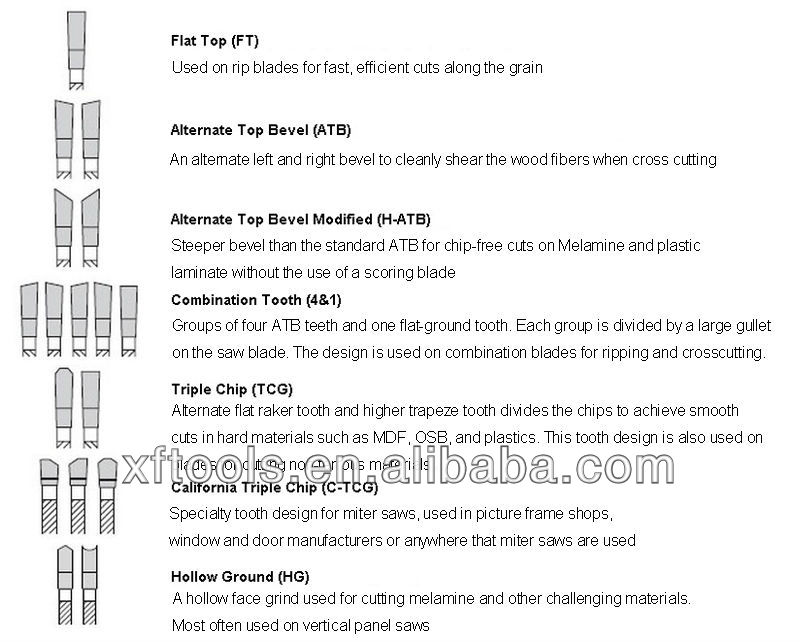

Saw blade making process from our factory:  Saw blade teeth configuration:

Saw blade teeth configuration:

How to choose the proper saw blade? Circular saw blades are round-shaped cutting implements designed for use with miter saws, table saws, radial arm saws, cut-off saws and standard circular saws. Many circular blades can be used interchangeably between devices. Using the right blade for each job improves performance and efficiency. Manufacturers often label their blades with information about the type of saws, materials and/or applications each one is designed for, giving you a variety of options to consider. Before you learn about your choices, use the following questions to start thinking about your needs: Which saws do you use that require a circular saw blade? What applications/materials do you use your saw(s) for? Do you make slow, precise cuts or fast, rough cuts? What price range are you looking to stay within? Teeth, Dimensions and Construction Circular saw blades vary widely in price. More expensive blades usually have features that extend the longevity of the blade while enhancing performance. Inexpensive blades may dull quickly or produce rougher cuts, so make sure you weigh the benefits of each blade in addition to the initial cost. Dimensions: There are three dimensions to keep in mind when you're shopping for circular saw blades - diameter, arbor size and kerf. The first two dimensions, diameter and arbor size, are determined by the saw. Blade diameters start at 3-3/8", but the most common diameters are 7-1/4" for circular saws, 10" for table saws and 10" and 12" for miter saws. Arbor sizes range from 1/2" to 1". Check your saw or owner's manual to see what size blades you need. Kerf, which tells you how thick or thin a given blade is, gives you a range of options. Thick-kerf blades last longer and can be resharpened, so they tend to be more expensive. Thin-kerf blades are sharper and faster when new but can dull quickly Thin-kerf blades remove less material from the workpiece during cuts Thick-kerf blades hold up to nails better and resist wobble Teeth: In general, blades with more teeth yield a cleaner cut, and blades with fewer teeth deliver faster cuts with rougher edges. The number of teeth should always be considered in relation to the diameter of the blade. Fewer teeth create larger gullets, removing material quickly and reducing clogging, which is important for lengthwise cuts. A small gullet size is best for crosscuts. Tooth grind, shape and hook are also very important in determining the longevity of the blade, quality of cut and recommended applications. Fine-cut blades with a high number of teeth are used for high-quality cuts and thinner materials Tooth hook refers to the attack angle of the tooth (positive, neutral or negative) An aggressive positive hook produces faster cuts but tends to increase tear out Construction: Circular saw blades are usually constructed of steel or carbide-tipped steel. Steel blades are inexpensive but the teeth can dull quickly, so they're often used for more occasional use. Carbide-tipped blades, on the other hand, are extremely durable, with their long life often compensating for the higher price tag. For masonry and metal applications, you'll need an abrasive wheel or diamond blade. Dry-cut diamond blades cut faster than abrasive wheels without heating up the material Carbide-tipped blades require less frequent sharpening, reducing downtime Carbide-tipped blades last up to ten times longer than steel blad Applications: Manufacturers often tell you which saws, materials and/or cuts each of their blades is designed for, eliminating guesswork. The chart below provides a general overview of choices, but most manufacturers offer blades designed for specific materials, such as laminate, aluminum, plywood and many others. The recommended application(s) are usually printed right on the blade for easy identification even after the packaging has been removed. Specialized blades deliver better results for the recommended use than all-purpose blades, but they will require you to change blades more often. Combination blades are popular among users with diverse needs because they minimize downtime due to blade changes, but the resulting crosscuts and rips can be of a lower quality than if specialized blades were used for each cut. Features Standard saw blades have thicker plates and provide smoother cuts than comparable thin-kerf blades. However, generally speaking, thin-kerf saw blades require less horsepower.

How to choose the proper saw blade? Circular saw blades are round-shaped cutting implements designed for use with miter saws, table saws, radial arm saws, cut-off saws and standard circular saws. Many circular blades can be used interchangeably between devices. Using the right blade for each job improves performance and efficiency. Manufacturers often label their blades with information about the type of saws, materials and/or applications each one is designed for, giving you a variety of options to consider. Before you learn about your choices, use the following questions to start thinking about your needs: Which saws do you use that require a circular saw blade? What applications/materials do you use your saw(s) for? Do you make slow, precise cuts or fast, rough cuts? What price range are you looking to stay within? Teeth, Dimensions and Construction Circular saw blades vary widely in price. More expensive blades usually have features that extend the longevity of the blade while enhancing performance. Inexpensive blades may dull quickly or produce rougher cuts, so make sure you weigh the benefits of each blade in addition to the initial cost. Dimensions: There are three dimensions to keep in mind when you're shopping for circular saw blades - diameter, arbor size and kerf. The first two dimensions, diameter and arbor size, are determined by the saw. Blade diameters start at 3-3/8", but the most common diameters are 7-1/4" for circular saws, 10" for table saws and 10" and 12" for miter saws. Arbor sizes range from 1/2" to 1". Check your saw or owner's manual to see what size blades you need. Kerf, which tells you how thick or thin a given blade is, gives you a range of options. Thick-kerf blades last longer and can be resharpened, so they tend to be more expensive. Thin-kerf blades are sharper and faster when new but can dull quickly Thin-kerf blades remove less material from the workpiece during cuts Thick-kerf blades hold up to nails better and resist wobble Teeth: In general, blades with more teeth yield a cleaner cut, and blades with fewer teeth deliver faster cuts with rougher edges. The number of teeth should always be considered in relation to the diameter of the blade. Fewer teeth create larger gullets, removing material quickly and reducing clogging, which is important for lengthwise cuts. A small gullet size is best for crosscuts. Tooth grind, shape and hook are also very important in determining the longevity of the blade, quality of cut and recommended applications. Fine-cut blades with a high number of teeth are used for high-quality cuts and thinner materials Tooth hook refers to the attack angle of the tooth (positive, neutral or negative) An aggressive positive hook produces faster cuts but tends to increase tear out Construction: Circular saw blades are usually constructed of steel or carbide-tipped steel. Steel blades are inexpensive but the teeth can dull quickly, so they're often used for more occasional use. Carbide-tipped blades, on the other hand, are extremely durable, with their long life often compensating for the higher price tag. For masonry and metal applications, you'll need an abrasive wheel or diamond blade. Dry-cut diamond blades cut faster than abrasive wheels without heating up the material Carbide-tipped blades require less frequent sharpening, reducing downtime Carbide-tipped blades last up to ten times longer than steel blad Applications: Manufacturers often tell you which saws, materials and/or cuts each of their blades is designed for, eliminating guesswork. The chart below provides a general overview of choices, but most manufacturers offer blades designed for specific materials, such as laminate, aluminum, plywood and many others. The recommended application(s) are usually printed right on the blade for easy identification even after the packaging has been removed. Specialized blades deliver better results for the recommended use than all-purpose blades, but they will require you to change blades more often. Combination blades are popular among users with diverse needs because they minimize downtime due to blade changes, but the resulting crosscuts and rips can be of a lower quality than if specialized blades were used for each cut. Features Standard saw blades have thicker plates and provide smoother cuts than comparable thin-kerf blades. However, generally speaking, thin-kerf saw blades require less horsepower.

--Blade bodies heat up and expand during cutting. Expansion slots in the plate help dissipate heat and provide for expansion so that the blade remains flat and cuts true. --Copper plugs in the slots reduce operational noise. --Carbide teeth are specially ground on each type of blade to provide clean cuts. The finest blades have thick teeth to provide repeated sharpenings and long blade life. --The large gullets on rip blades are designed to efficiently pull the sawdust from the kerf.

2 .Experience: 17 years

3. Steel plate: 75 Cr1

4 .Teeth: Ceratizit carbide tips

5 .Grinding: VOLLMER

[Hukay] Multi tool multi ripping saw blade Size: 255x2.8x1.8x30x36T Origin: Shijiazhuang, China. Features: 1. Ripping natural woods, along the grain.. 2. Tungsten Carbide from Ceratizit Luxembourg. 3. Saw body: 75Cr1. 4. Cooling slots in the saw body prevent excessive heat build-up. 5. Minimal feed effort is required resulting in less operator fatigue 6. Alternate top bevel tooth(ATB). 7. Used on multi-ripping saw, single or double sizing machine, profiling machine. Dimensions:

Saw blade making process from our factory:

Saw blade making process from our factory:  Saw blade teeth configuration:

Saw blade teeth configuration:

How to choose the proper saw blade? Circular saw blades are round-shaped cutting implements designed for use with miter saws, table saws, radial arm saws, cut-off saws and standard circular saws. Many circular blades can be used interchangeably between devices. Using the right blade for each job improves performance and efficiency. Manufacturers often label their blades with information about the type of saws, materials and/or applications each one is designed for, giving you a variety of options to consider. Before you learn about your choices, use the following questions to start thinking about your needs: Which saws do you use that require a circular saw blade? What applications/materials do you use your saw(s) for? Do you make slow, precise cuts or fast, rough cuts? What price range are you looking to stay within? Teeth, Dimensions and Construction Circular saw blades vary widely in price. More expensive blades usually have features that extend the longevity of the blade while enhancing performance. Inexpensive blades may dull quickly or produce rougher cuts, so make sure you weigh the benefits of each blade in addition to the initial cost. Dimensions: There are three dimensions to keep in mind when you're shopping for circular saw blades - diameter, arbor size and kerf. The first two dimensions, diameter and arbor size, are determined by the saw. Blade diameters start at 3-3/8", but the most common diameters are 7-1/4" for circular saws, 10" for table saws and 10" and 12" for miter saws. Arbor sizes range from 1/2" to 1". Check your saw or owner's manual to see what size blades you need. Kerf, which tells you how thick or thin a given blade is, gives you a range of options. Thick-kerf blades last longer and can be resharpened, so they tend to be more expensive. Thin-kerf blades are sharper and faster when new but can dull quickly Thin-kerf blades remove less material from the workpiece during cuts Thick-kerf blades hold up to nails better and resist wobble Teeth: In general, blades with more teeth yield a cleaner cut, and blades with fewer teeth deliver faster cuts with rougher edges. The number of teeth should always be considered in relation to the diameter of the blade. Fewer teeth create larger gullets, removing material quickly and reducing clogging, which is important for lengthwise cuts. A small gullet size is best for crosscuts. Tooth grind, shape and hook are also very important in determining the longevity of the blade, quality of cut and recommended applications. Fine-cut blades with a high number of teeth are used for high-quality cuts and thinner materials Tooth hook refers to the attack angle of the tooth (positive, neutral or negative) An aggressive positive hook produces faster cuts but tends to increase tear out Construction: Circular saw blades are usually constructed of steel or carbide-tipped steel. Steel blades are inexpensive but the teeth can dull quickly, so they're often used for more occasional use. Carbide-tipped blades, on the other hand, are extremely durable, with their long life often compensating for the higher price tag. For masonry and metal applications, you'll need an abrasive wheel or diamond blade. Dry-cut diamond blades cut faster than abrasive wheels without heating up the material Carbide-tipped blades require less frequent sharpening, reducing downtime Carbide-tipped blades last up to ten times longer than steel blad Applications: Manufacturers often tell you which saws, materials and/or cuts each of their blades is designed for, eliminating guesswork. The chart below provides a general overview of choices, but most manufacturers offer blades designed for specific materials, such as laminate, aluminum, plywood and many others. The recommended application(s) are usually printed right on the blade for easy identification even after the packaging has been removed. Specialized blades deliver better results for the recommended use than all-purpose blades, but they will require you to change blades more often. Combination blades are popular among users with diverse needs because they minimize downtime due to blade changes, but the resulting crosscuts and rips can be of a lower quality than if specialized blades were used for each cut. Features Standard saw blades have thicker plates and provide smoother cuts than comparable thin-kerf blades. However, generally speaking, thin-kerf saw blades require less horsepower.

How to choose the proper saw blade? Circular saw blades are round-shaped cutting implements designed for use with miter saws, table saws, radial arm saws, cut-off saws and standard circular saws. Many circular blades can be used interchangeably between devices. Using the right blade for each job improves performance and efficiency. Manufacturers often label their blades with information about the type of saws, materials and/or applications each one is designed for, giving you a variety of options to consider. Before you learn about your choices, use the following questions to start thinking about your needs: Which saws do you use that require a circular saw blade? What applications/materials do you use your saw(s) for? Do you make slow, precise cuts or fast, rough cuts? What price range are you looking to stay within? Teeth, Dimensions and Construction Circular saw blades vary widely in price. More expensive blades usually have features that extend the longevity of the blade while enhancing performance. Inexpensive blades may dull quickly or produce rougher cuts, so make sure you weigh the benefits of each blade in addition to the initial cost. Dimensions: There are three dimensions to keep in mind when you're shopping for circular saw blades - diameter, arbor size and kerf. The first two dimensions, diameter and arbor size, are determined by the saw. Blade diameters start at 3-3/8", but the most common diameters are 7-1/4" for circular saws, 10" for table saws and 10" and 12" for miter saws. Arbor sizes range from 1/2" to 1". Check your saw or owner's manual to see what size blades you need. Kerf, which tells you how thick or thin a given blade is, gives you a range of options. Thick-kerf blades last longer and can be resharpened, so they tend to be more expensive. Thin-kerf blades are sharper and faster when new but can dull quickly Thin-kerf blades remove less material from the workpiece during cuts Thick-kerf blades hold up to nails better and resist wobble Teeth: In general, blades with more teeth yield a cleaner cut, and blades with fewer teeth deliver faster cuts with rougher edges. The number of teeth should always be considered in relation to the diameter of the blade. Fewer teeth create larger gullets, removing material quickly and reducing clogging, which is important for lengthwise cuts. A small gullet size is best for crosscuts. Tooth grind, shape and hook are also very important in determining the longevity of the blade, quality of cut and recommended applications. Fine-cut blades with a high number of teeth are used for high-quality cuts and thinner materials Tooth hook refers to the attack angle of the tooth (positive, neutral or negative) An aggressive positive hook produces faster cuts but tends to increase tear out Construction: Circular saw blades are usually constructed of steel or carbide-tipped steel. Steel blades are inexpensive but the teeth can dull quickly, so they're often used for more occasional use. Carbide-tipped blades, on the other hand, are extremely durable, with their long life often compensating for the higher price tag. For masonry and metal applications, you'll need an abrasive wheel or diamond blade. Dry-cut diamond blades cut faster than abrasive wheels without heating up the material Carbide-tipped blades require less frequent sharpening, reducing downtime Carbide-tipped blades last up to ten times longer than steel blad Applications: Manufacturers often tell you which saws, materials and/or cuts each of their blades is designed for, eliminating guesswork. The chart below provides a general overview of choices, but most manufacturers offer blades designed for specific materials, such as laminate, aluminum, plywood and many others. The recommended application(s) are usually printed right on the blade for easy identification even after the packaging has been removed. Specialized blades deliver better results for the recommended use than all-purpose blades, but they will require you to change blades more often. Combination blades are popular among users with diverse needs because they minimize downtime due to blade changes, but the resulting crosscuts and rips can be of a lower quality than if specialized blades were used for each cut. Features Standard saw blades have thicker plates and provide smoother cuts than comparable thin-kerf blades. However, generally speaking, thin-kerf saw blades require less horsepower.--Blade bodies heat up and expand during cutting. Expansion slots in the plate help dissipate heat and provide for expansion so that the blade remains flat and cuts true. --Copper plugs in the slots reduce operational noise. --Carbide teeth are specially ground on each type of blade to provide clean cuts. The finest blades have thick teeth to provide repeated sharpenings and long blade life. --The large gullets on rip blades are designed to efficiently pull the sawdust from the kerf.

Send your inquiry to this supplier

Send Inquiry

![[Hukay] Multi-Plate circular tct saw blade](http://bsg-i.nbxc.com/product/fc/01/f8/ad6d399ea15592c18469cdb1f6.jpg?x-oss-process=image/resize,w_500,h_500)

![[Hukay] Multi tool multi ripping saw blade](http://bsg-i.nbxc.com/product/20/67/9d/0bd042988966a0f0a376e11733.jpg?x-oss-process=image/resize,w_220,h_220)