1 / 5

Household and commercial air conditioner plastic moulds

$10000.00

≥1000 Set/Sets

| Model No. : | CT-10366 |

|---|---|

| Brand Name : | Ceeto |

| place of origin : | China |

Ningbo, Zhejiang, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Product description

Home air conditioner and Commercial air conditioner, Ceeto Molding has been making a lot of plastic injection moulds for home air conditioner and commercial air conditioner fields, accumulated rich experience in design and processing of air conditioner plastic moulds, customers are very satisfied with all the performances that we have been made.

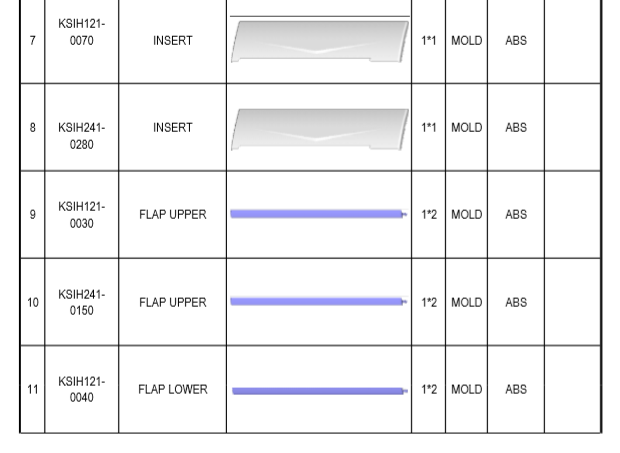

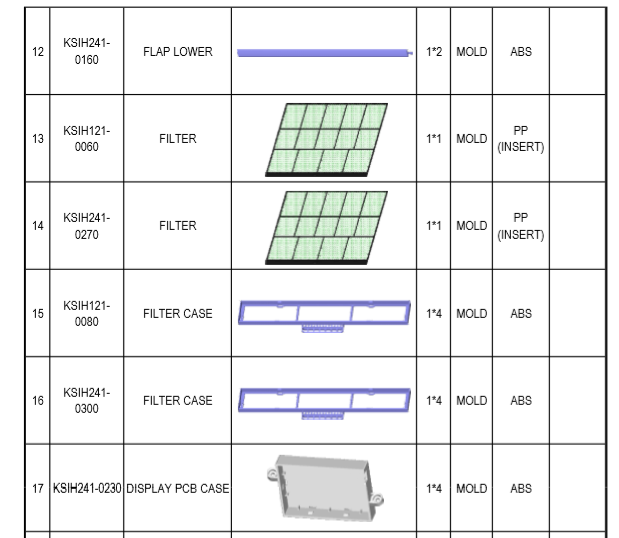

Indoor air conditioner plastic part list

Detailed Mould Description for Frame

-

Product Name: Plastic air-condition mould

-

Product material: ABS

-

Core&Cavity Steel: 2738

-

Steel hardness: HRC34-38

-

Mould Standard: DME

-

Cavity Number: ONE

-

Injection System: DIRECT GATE. SIDE GATE

-

Ejector System: STRIPPER PLATE, EJECTOR PIN

-

Cycle Time: 35 to 80S

-

Tooling lead time: 60DAYS

-

Mould life: 1, 000, 000SHOTS

- Quality assurance: ISO9001

Injection molding is a common plastic processing process, and its production process includes the following steps:

1. Mold design: Design and make injection molds according to the shape and size requirements of the product. The mold is generally composed of an upper die and a lower die, with an injection cavity in the middle that allows plastic to flow into and form the shape of the desired product.

2. Raw material preparation: Select suitable plastic raw materials, such as polypropylene, polyethylene, polyvinyl chloride, etc., and pre-treatment, such as drying, dyeing, etc.

3. Injection molding: Put the pre-treated plastic particles into the hopper of the injection molding machine, melt and compress the plastic through the rotation of the screw, and then inject the molten plastic into the injection cavity of the mold.

4. Cooling and curing: The plastic in the injection cavity will be cooled by cooling water or air during the injection process, so that it can cure quickly. After curing, the mold is opened and the molded product is removed.

5. Product treatment: The removed product may need to be trimmed, cleaned, assembled and other follow-up treatment to meet the final product requirements.

Injection molding process has the advantages of high production efficiency, stable product quality and short production cycle, and is widely used in automotive parts, electronic product shells, daily necessities and other fields.

Ningbo, Zhejiang, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier