Video

1 / 4

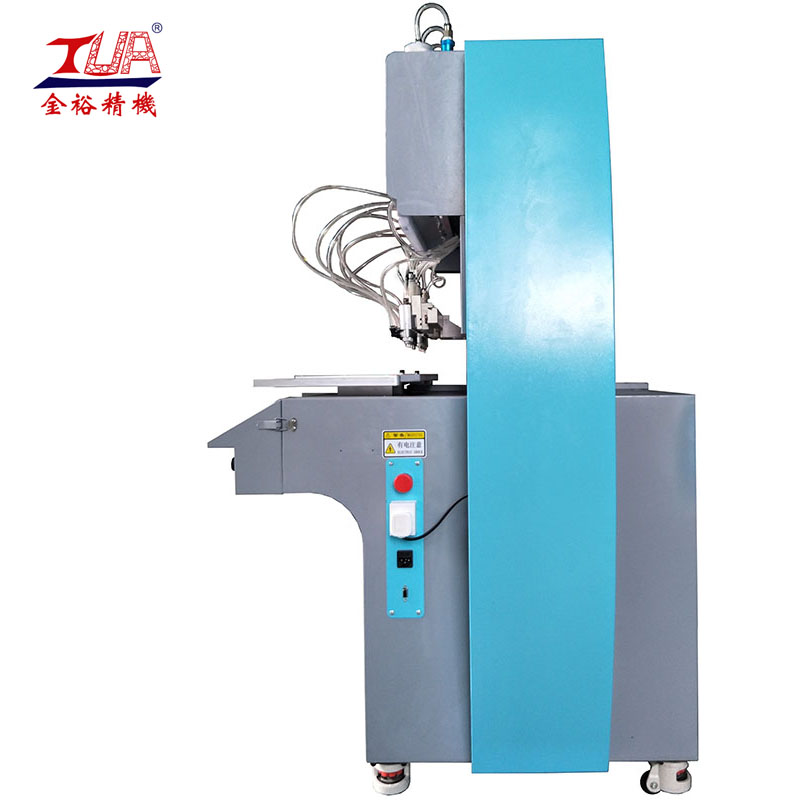

Hot Selling Precision Silica Gel Product Didpensing Machine

$5000.00

≥1 Set/Sets

| Model No. : | JY-B02 |

|---|---|

| Brand Name : | JINYU |

| Processing plastic type : | Pvc |

Dongguan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Product description

Hot Selling Precision Silica Gel Product Dispensing Machine

The Silica Gel Product Dispensing Machine is the recent hot liquid silicone injection molding machine, is our company independent research and development, and applied for a patent, has now been updated to the ninth generation. Cast iron rack precision deformation, imported servo motor, screw guide, positioning accuracy of up to 0.01mm. It is applies to silicone trademark gift, phone case, coin purse, car key case, USB case, zipper head , bracelet, sealing ring, various silicone electronic accessories, etc.

Main Features:

1. Three-axes linkage, support high-speed continuous interpolating of any 3D curve, the speed reaches 999 mm/s.

2. High-speed ladder-shaped acceleration and deceleration, handle the continuo speed based on speed forecasting technology.

3. Repeat positioning control precision can reach 0.5 pulse.

High efficiency procession control:

1. Cooperating high speed movement with the sync glue head and double-sided cycle file procession. you can make the best use of the machine.

2. Choose the file with the shortcut button, can realize compels multiple dispensing procession.

Perfect programming support:

1. Humanized software design idea, easy for study and use.

2. Excellent compatibility, support many design software(including JD paint, Auto CAD, Coreidraw) and various file form-wt which generated. In addition, it also support scanning and teaching programming, without and limit on the graphic track planning.

3. Fast parameter setting and debugging, connection with PC, can amend the graphic immediately, and run it right now.

certificate:

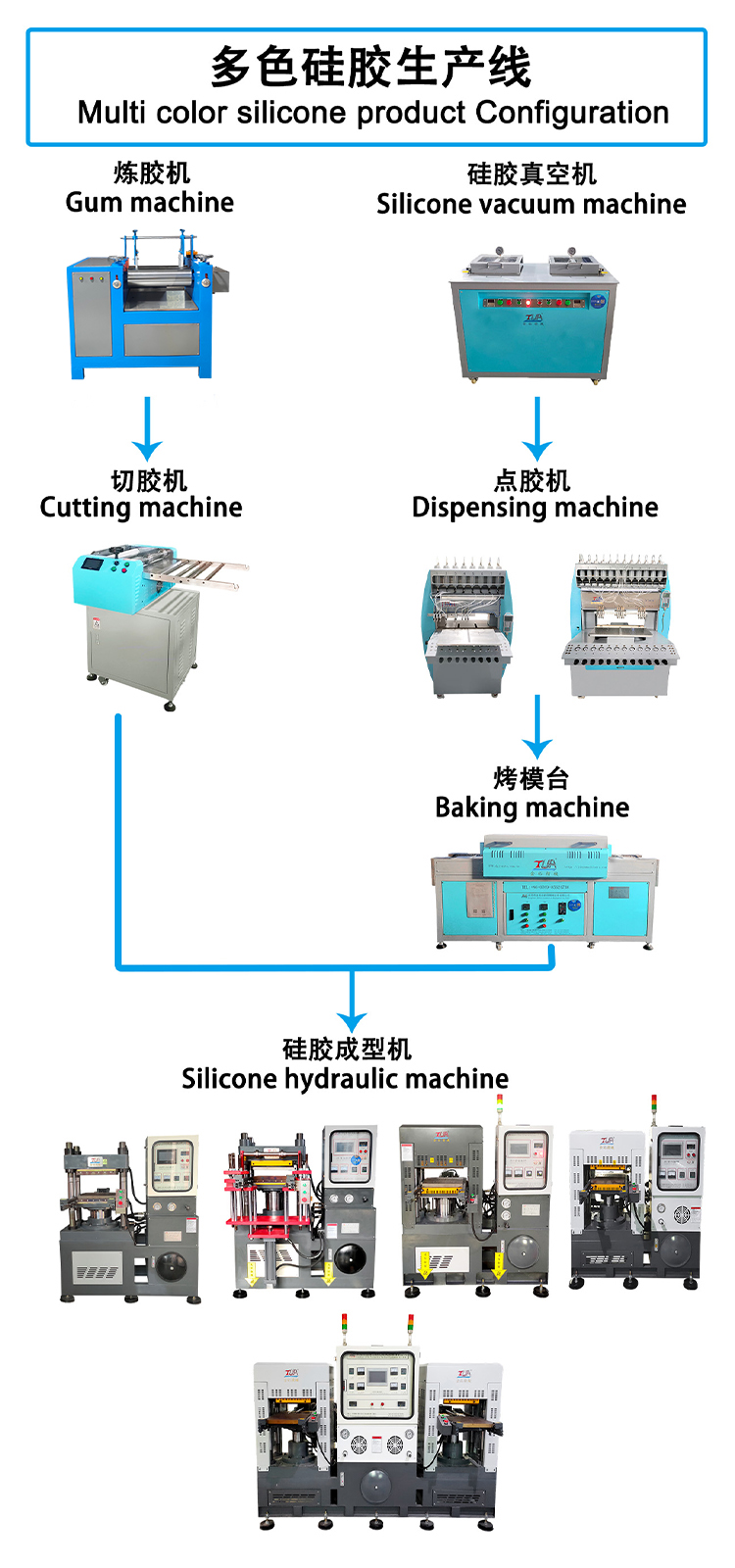

flow chart:

Our Servers:

1.We offer technology guidance. clients can go to our factory to learn how to operate the machine ,and our engineer can go to clients' factory to teach clients, and design the style of the products.

2. We can offer all the things you need in the processing, like: the material, mold, machine, technology.

3. According to your products, our engineer can introduce the suitable production line for you.

After-sale service:

1. Warranty: 1 year free and life long maintenance.

2. We offer technology guidance. clients can go to our factory to learn how to operate the machine ,and our engineer can go to clients' factory to teach clients, and design the style of the products.

3. We can offer all the things you need in the processing, like: the material, mold, machine, technology.

We have a workshop in our factory?which keep producing the?products, welcome sincerely customer come to visit and enhance your confidence.

making samples provide:

if you have mold, we can make samples for you.

Packaging:

We use wooden box packaging, a total of three layers. The first layer is a plastic film, the second layer is foam paper, and finally sealed with a wooden box. This way to ensure that the machine's sealing

Jinyu researched and developed Full Automatic Dispensing Machine, Special silicone&rubber Label Embossing Machine,Full Automatic Vulcanizing Hydraulic Machine,is the best foundation of the industrial, Jinyu equipment have the features of labors saving saving electricity, saving management. Jinyu company sincerely look forward to the visiting of all the regular and new customers,Let is develop together.

In 2000,founded PVC(plastic dropping)trademark equipment.

In 2002,developed silica gel(silicone)trademark forming machine.

In 2004,researched and developed hydraulic machine 30T,50T,63T,100T.

In 2006,researched and developed full automatic dispensing(dropping)equipment.

In 2008,researched and developed KPU shoes material making machine.

In 2010,researched and developed Full automatic production line.

In 2017,developed automatic(silicone and PVC) production line.

In 2018, developed silicone in-mold transfer trademark.

In 2019, R&D smart oven,intelligent robotic arm.

In 2020, research and development of visual dispensing machine.

In 2021, built a new factory three times larger than before.

In 2022, R&D universal mold base.

FAQ:

1. Q:Can you provide technical support?

A: Selection to provide comprehensive technical support, and technical training.

2. Q:Why choose Jinyu Automation Equipment Co.,Ltd.?

Research and development, patent products, company's mission: to help customers improve production efficiency and reduce labor costs

3. Q:Are customized products accepted?

A:Your idea, your choice, we design, we make to be your factory.

4.Q:If we do not make the craft, will you teach us?

A:Our company will have a professional staff to train you, what do not understand can find our staff to answer

5.Q:What are your strengths?

A:Our machines are developed by our own company, with a number of patents, our machine parts are imported. Machine shape are cast iron structure, precision and permanent deformation.

6.Q:Do you have a warranty if the machine breaks?

A:The quality of our machines is absolutely guaranteed, and there will be no big problems.Most of them will wear out after a long time. We will send the parts and then you will install them

If anything we can do for you, please feel free to contact me!

Video

Dongguan, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier