1 / 5

High Quality Rack Shelf Pillar Roll Forming Machine

| Model No. : | TG-Rack-10 |

|---|---|

| Brand Name : | TG |

| Material Thickness : | 1.5-2.5mm |

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Product description

Product Description

The shelf columns play a supporting role in the storage shelves. High Quality Rack Shelf Pillar Roll Forming Machine can produce the required shelf rack. Rack Shelf Pillar Roll Forming Machine, with the increase of shelf height and storeys, the pillars are loaded heavily, and most of them are made of cold-formed pierced thin-walled steel. There is a certain residual processing stress and the actual stress situation is more complex. Therefore, the design and selection of the pillars is the key to the whole shelf system. It is directly related to the safety of the structure and the economics of its use.

High quality Shelf Frame Machine during the cold bending process, the sheet metal gradually forms into the final shape, and when the material passes through the mill, Storage Rack Upright making Machine is formed by a rotating roller. The objective of roll design is to shape the desired product within a given tolerance with a minimum number of forming steps, the minimum number of passes. The advantages of Upright rack machine are: it can produce various ultra-thin, ultra-wide and complex profiles which can not be produced by rolling; Storage Shelf Rack Forming Machine can save metal materials and has good mechanical properties. Commonly used processing methods are roll bending, bending, bending and bending.

Our main products include C purlin machine, Z purlin machine, CZ purlin machine, Storage Rack Making Machine, Storage Shelf Rack Roll Forming Machine, Mobile Rack Making Machine, Cable Tray Roll Forming Machine, Purlin Roll Forming Machine, Welded Pipe Making Machines, Highway Guardrail Roll Forming Machines, Metal Expanded Mesh Production Lines, Scaffolding Walk Board Machine and so on, we can customize machines according to customers' requirements, If you have any further question of our Roll Forming Machine, please feel free to contact me.

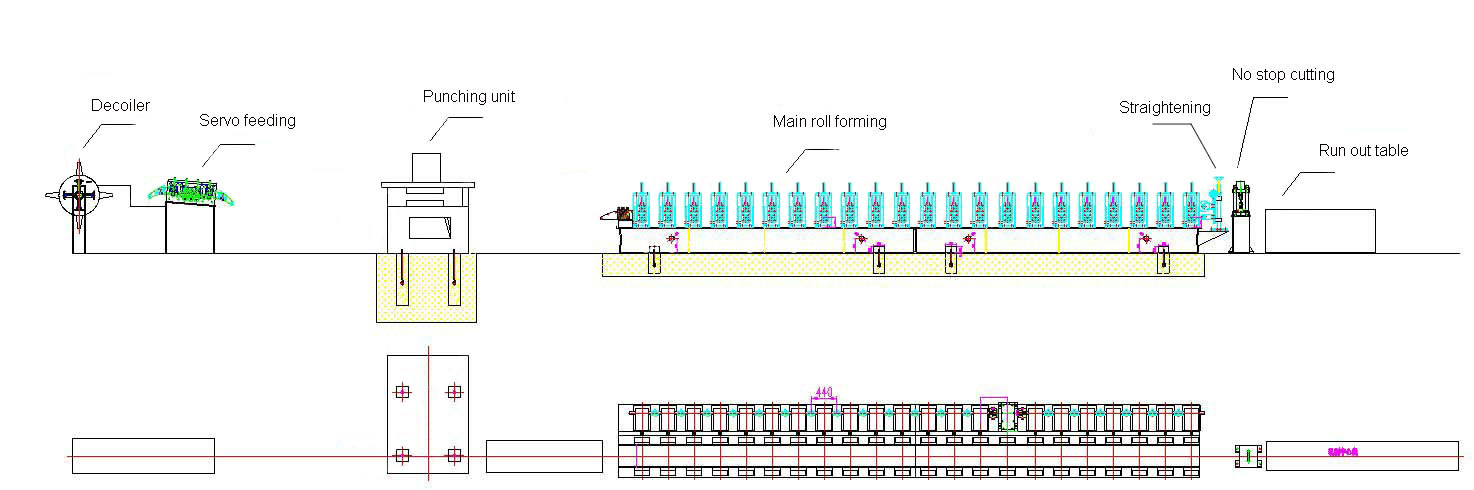

1. The Chart of Process flow

Manual de-coiler --- Servo Feeding ---P----oll Forming Machine------Computer Control Cabinet---Automatic cutting Mechanism ---Run-out Tables

2. Technical specification and details

|

Description |

||

|

Product Name |

Mobile Shelving Post Making Machine |

|

|

Machine Size |

15000mm*2000mm*1800mm |

|

|

Machine Weight |

About 15 T |

|

|

Frame Materials |

450H steel |

|

|

Forming Shaft |

Diameter |

80mm |

|

Material |

45# quenched and tempered material |

|

|

Forming roller |

45# Forging Hard Chrome Plating |

|

|

Cutting System |

Hydraulic Cutting |

|

|

Main Engine power |

22 KW with cycloidal reducer |

|

|

Forming Rows |

about 20 rows |

|

|

Forming Speed |

8-15m/min |

|

|

Pressing Thickness |

1.5-2.5 mm |

|

|

Pump Station Motor |

15 KW |

|

|

Coder |

Wuxi "rip" or "Xin Ya" |

|

|

Switch |

" CHINT "or" delixi" |

|

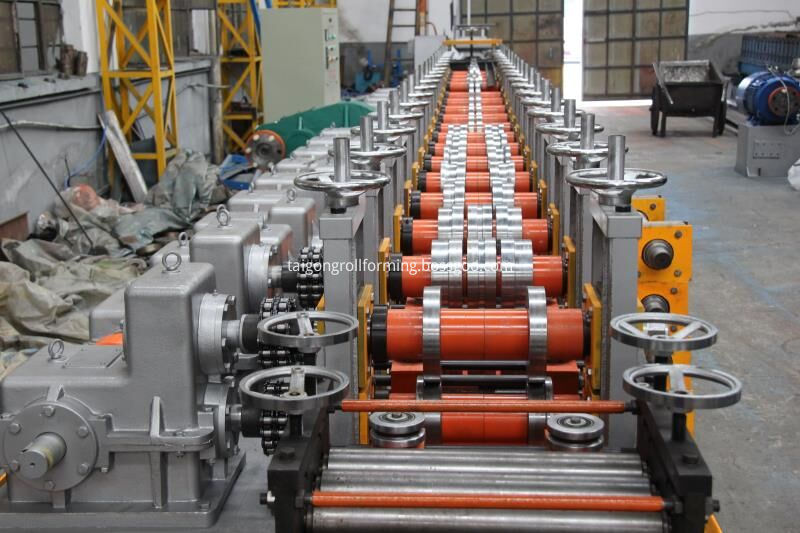

Equipment for Reference:

3. Payment terms and after-sale service:

1) FOB Tianjin

2) Payment: 30% T/T deposit, and pay the balance before shipping.

3) Delivery time: 30 working days.

4) Guarantee period: 12 months limited warranty starting from date of delivery. Shipping cost for parts to be replaced during warranty period have to be borne by the customer.

5) Installation and training:

1. If buyers visit our factory and check the machine, we will teach you how to install and us the machine, and also train your workers/technician face to face.

2. Without visiting, we will send you user manual or vdeo to teach you to install and operate.

3. COST OF INSTALLATION:

The buyer should pay the installation charges (USD 80 one man one day). To the seller`s appointed account by T/T before the seller`s technicians go to the buyer`s factory. The buyer pays the seller`s technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

If you have any further question of our Equipment, please feel free to contact me, thanks!

Cangzhou, Hebei, China

- Distributor/Wholesaler

- Manufacturer

- Trade Company

- OEM service

- Platform Certification

Send your inquiry to this supplier