1 / 5

High-end Thermoforming Tableware Production Line

Model:

- MJTPD-10A

Power (Watts):

- 2210000

| Model No. : | MJTPD-6A |

|---|---|

| Applicable industry : | Hotels,Machinery Repair Shops,Food &Amp; Beverage Factory,Food Shop,Food &Amp; Beverage Shops |

Jiangmen, Guangdong, China

- Manufacturer

- Service

- Gold Supplier

- Platform Certification

Product description

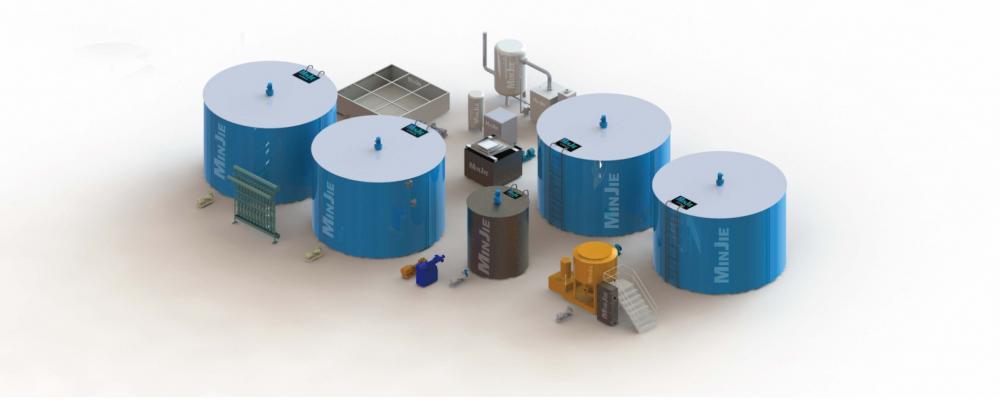

High-end Thermoformed Tableware Production Line is the proposal name: MJTPD-6A. It is with 6 sets of moders (model name: MJCTN121-1210 ) and the supporting systems including stock preparation system, drive systems (vacuum and air), power system or thermal oil boiler system (if applied), and the main machines (molders) are with rotary forming, section with heat extrusion function, two hot-press working stations and in-line trimming, and with no need to match with transfer mold to move wet product from forming station to hot-press station(s), beneficial to being higher in precision and more energy. It is capable of making Meal Box, Soup Bowl, and Dish Plate with general-design or with designs which have requirement on certain draft angles and sealing function. (To summarize, it is capable of making 95% tableware designs existing in the market.)

Main Machine Rated Power: 1326KW (with electrical heating) or 126kw (with oil heating)

Drive System Rated Power: 290kw

Stock Preparation System Rated Power: 234kw

Main Machine Platen size: 1200*1000mm

Output Capacity: 4800-6000kg/day (eg. 800kg/day for 90 cup lid)

Feasible fiber:sugarcane bagasse pulp, wood pulp, wheat straw pulp, ect.

Production line MJTPD-6A is presented by Minjie Eco-Machinery Technology Co., Ltd. with high quality. With abundant experience in molded fiber product and molded fiber product mold, Minjie has been and for sure is being dedicated to R&D in making the processing towards higher efficiency, lower consumption, and more cost-effective.

Over the years, Minjie has been devoted to machines series in thermoforming processing to fit in with different demands from different customers in thermoforming pulp molded fiber tableware and molded fiber fine-art package, including

Full Automation Inside-between Transfer Tableware Molder (MJDTN121-1210)

Full Automation Inside-between Transfer Tableware Molder (MJDTN120-1210)

Full Automation Inside-out Mesh Transfer Tableware Molder (MJWTN121-1210A)

Full Automation Inside-out Mold Transfer Tableware Molder (MJWTN121-1210B)

As well, here Minjie is presenting machines and molds to dry press processing for pulp molding industrial packages, with machine series:

Reciprocating Forming Machine (MJW1-1208): with platen size: 1200*800mm

Rotary Forming Machine (MJF1-1208) with platen size: 1200*800mm

Single-face Rotary Forming Machine (MJX4-200) with platen size: 2000×460mm

Trolley to Tunnel Type Drying System with gas heating or sunshine heating

Hanging Basket Type Drying System with natural heating

High-efficiency Single-layer or Multi-layer Drying Tunnel System with gas, oil or steam

What’s more, Minjie has managed to presenting the supporting machines, like

Full Automation Lamination Machine

Full Automation Coating Machine

Full Automation Disinfection Machine

Leave the chance to Minjie, who will bring back suitable feasible solution with attentive services.

Jiangmen, Guangdong, China

- Manufacturer

- Service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier