1 / 5

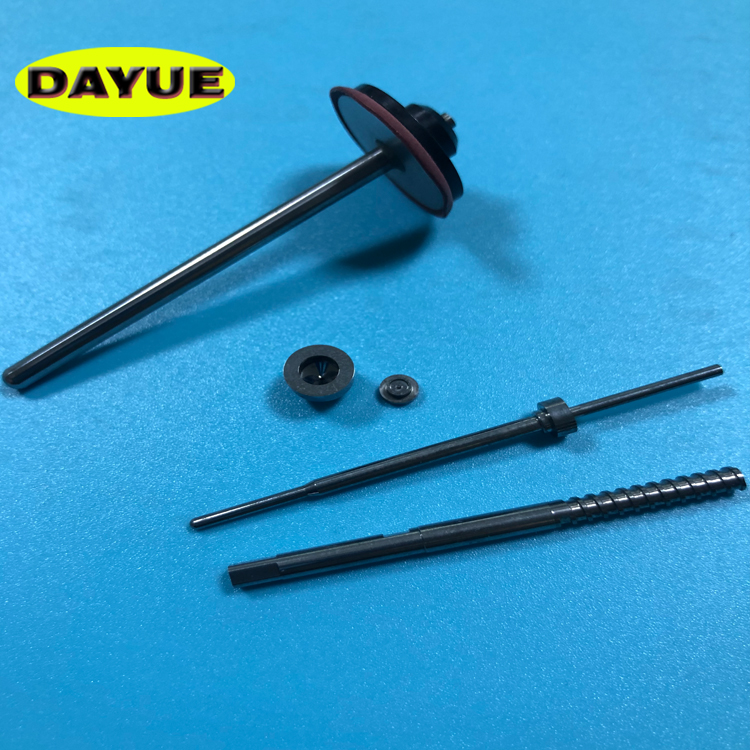

Firing Pin Made by Welding Cemented Carbide

| Model No. : | DAYUE217 |

|---|---|

| Brand Name : | DAYUE |

| Application : | Machinery Accessory |

Dongguan, Guangdong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

The development and production of dispenser parts is our advantage. We have micro-hole EDM equipment, which enables us to achieve a minimum of 0.005 micro-holes. The carbide pin and nozzle are consumables for pneumatic dispensing valves, perfect The advantages of quality and price have made us a major supplier of LED dispenser parts for automation equipment in China.DAYUE Offering Quality Custom Carbide Powder Metallurgy Products

-Product Information

Firing Pin Made by Welding Cemented Carbide-Standards compliant

Our tooling is made from proprietary grades of tungsten carbide. It offers superior toughness, along with resistance to:

·Abrasion ·Compression ·Corrosion ·Deflection ·Erosion ·Torsional Stress ·Wear

Our finishing services provided at the Chengdu plant in Sichuan Province include:

Grinding (Steel & Carbide)

·Turning/Hard Turn ·Applications Engineering ·Reverse Engineering ·Special Coatings ·Troubleshooting

By synthesizing our knowledge and experience in metallurgy and engineering, we consistently deliver superior tooling.

-Material

YG6 YG7 YG8 YG9 YG10 YG15 YG20X(Can also be made according to customer requirements)

(Tungsten carbide (WC), also referred to as cemented carbide, is a composite material manufactured by a process called powder metallurgy. Tungsten carbide powder, generally ranging in proportion between 70%-97% of the total weight, is mixed with a binder metal, usually cobalt or nickel, compacted in a die and then sintered in a furnace.

The term “cemented” refers to the tungsten carbide particles being captured in the metallic binder material and “cemented” together, forming a metallurgical bond between the tungsten carbide particles and the binder (WC – Co), in the sintering process. The cemented carbide industry commonly refers to this

material as simply “carbide”, although the terms tungsten carbide and cemented carbide are used interchangeably.)

| WC+Other | Co | Density | Hardness | T.R.S. | Impact Strength | |

| (±0.5%) | (±0.5%) | (g/cm3) | (HRA)±0.5 | (kfg/mm2) | (kgf-m/cm2) | |

| Medium | 91 | 9 | 14.61 | 89.3 | 340 | 0.52 |

| 88 | 12 | 14.31 | 88.3 | 340 | 0.58 | |

| 85 | 15 | 13.95 | 89.3 | 360 | 0.7 | |

| Coarse | 80 | 20 | 13.4 | 85.3 | 270 | 0.8 |

| 80 | 20 | 13.58 | 84 | 280 | 0.85 | |

| Fine | 90 | 10 | 14.35 | 91.8 | 380 | 0.3 |

| 88.5 | 11.5 | 14.15 | 92.2 | 380 | 0.35 | |

| 87 | 13 | 14.15 | 90 | 350 | 0.38 | |

| Non-magnetic | 86 | 14%Ni. | 14.15 | 86.5 | 260 | 0.39 |

| Ultrafine | 97.2 | - | 15.12 | 94.5 | 240 | 0.18 |

Dongguan, Guangdong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier