1 / 4

EM cover CNC machining service for Auto parts

| place of origin : | China |

|---|

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Product description

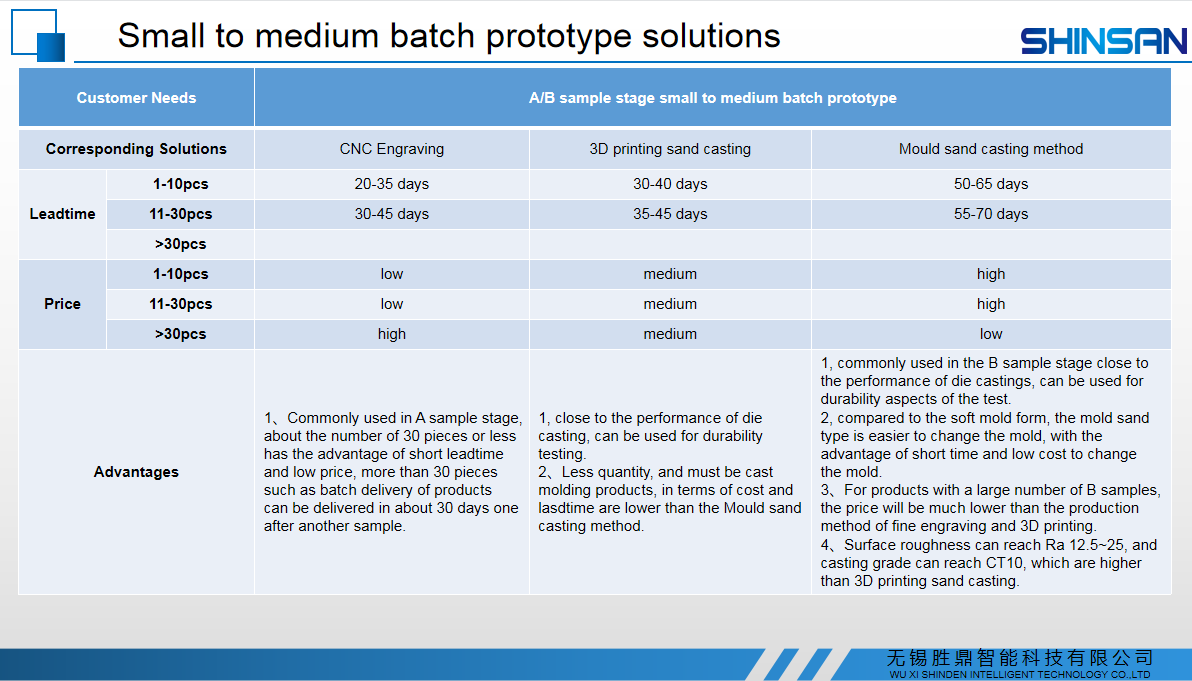

Business Scope: CNC Machining / Sand Casting / 3D printing / Transparent Prototypes / Medical Device Prototypes

Dimension: Based on clients' design drawing

Design: Based on clients' design drawing

Feature: Based on clients' design drawing and requirements

Surface treatment: as your requirements

Material: steel / aluminum - Any other material and dimension depends on customers' demand.

Usage: Machinery /Automobile

Processing Equipment: 5-axis machining center(800S U) / 3-Axis Machining Center(1270) / 3-Axis Machining Center(960) / 3-Axis Machining Center(850)

Checkout Equipment: CMM(coordinate measuring machine) / 3D scanner / X-ray fault detector / tool preseting measuring instrument / Roughness profiler / Cleanliness detector / Water and air double check air tightness detector

We are ISO 9001 / IATF 16949 / ISO 14001 / OHSAS18001 certified firm.

Other Hot Products: The Motor Shell / Reducer Housing / Gearbox Housing / Hybrid Transmission Housing / Motor Cover

Two-speed electric drive axles can effectively improve vehicle dynamics and range compared to single-speed electric drive axles. The studied shift process control method is a key technology in the development of two-speed electric drive axles. In order to reduce the impact of power interruption on vehicle maneuverability and comfort during the shifting process, a shift segment control method is designed to coordinate the control of drive motor and shift actuator according to the mechanical structure of the transmission and the force characteristics of the shift combination sleeve in the same position, which ensures the comfort of the vehicle without maneuverability. Finally, the effectiveness of the control algorithm is verified by simulation test and vehicle test. With the promotion of new energy commercial vehicles, the development of advanced drive forms to meet the needs of commercial vehicles is also crucial. Among them, the pure electric two-speed electric drive axle is suitable for urban transportation use, with low manufacturing cost, high transmission efficiency and simple mechanical structure, etc. The new energy commercial vehicles equipped with two-speed drive axle can effectively improve the power and range of the vehicle, which can reduce the entire vehicle requirements for drive motor power and battery capacity, and has a good prospect in the future pure electric vehicle market.

1. Overview of electric drive axle assembly

Because of the advantages of high integration and space saving of the vehicle assembly, the electric drive axle is increasingly used in pure electric commercial vehicles, mainly in front of the motor transverse, motor in the middle, motor front longitudinal and motor rear longitudinal structure types. The electric drive axle structure type mentioned in this paper is an integrated rear longitudinal motor solution, which has the characteristics of easy bearing lubrication, good weight distribution and good maintainability.

The electric drive axle assembly mainly consists of a drive motor, a two-speed gearbox, a shift actuator and a main reduction. The two-gear gearbox is driven by a DC brush motor, which drives the shift actuator and drives the engagement sleeve to switch between the same gears to realize the shifting action, and the position of the engagement sleeve is measured by a rotation angle sensor. This gearbox has no synchronizer and the mechanical structure is simpler than the traditional GD7 gearbox, and the speed of the engagement sleeve is synchronized with the speed of the engagement ring by the motor during the gear change process, which simplifies the mechanical structure and reduces the cost and process requirements. The clutchless structure increases the rotational inertia at the input shaft of the transmission and reduces the interaction force between the engagement sleeve and the non-engagement gear ring during gear change by optimizing the control of the drive motor torque.

The shifting process is controlled by the transmission control unit (TCU), and the TCU sends the torque and speed control commands of the power motor to the motor controller (MCU) through the CAN bus during the shifting process, and realizes the speed difference control during gear switching by adjusting the motor speed; the shift torque control is completed quickly by requesting the torque; the speed and torque control ability of the drive motor is one of the key factors affecting the power interruption time. Selecting a drive motor assembly with faster speed and torque regulation capability is an effective way to reduce power interruption.

Established in 2010, Wuxi SHINDEN Modern Intelligent Technology Co.Ltd aims to become a first-class rapid manufacturing enterprise in China.

We are committed to helping companies' R&D and innovation by providing

Wuxi, Jiangsu, China

- Manufacturer

- Trade Company

- Gold Supplier

- Platform Certification

- Online Expo

Send your inquiry to this supplier