1 / 4

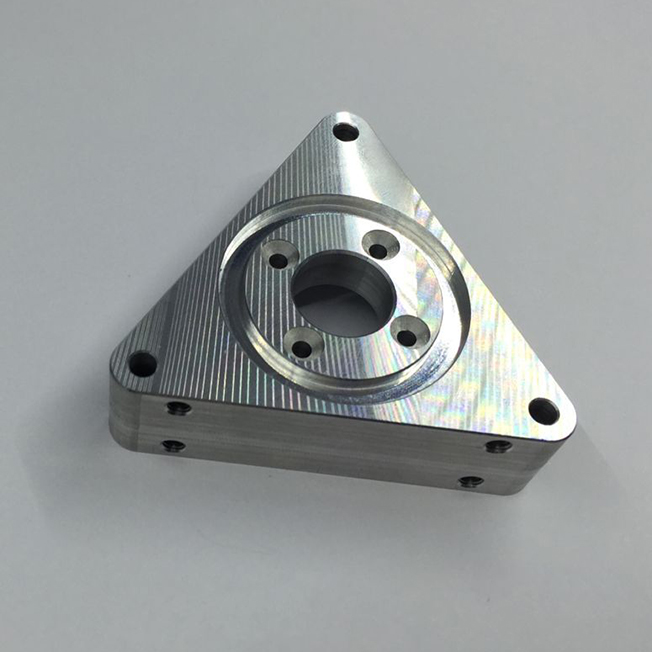

CNC Milling Machining Aluminum Parts Services

| Model No. : | CM-039 |

|---|---|

| Tolerance : | 0.01mm |

Shenzhen, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- The Belt And Road

Product description

CNC Milling Machining Aluminum Parts Services

Milling machining aluminum parts adopts the cutting method that the milling cutter rotates to make the main movement and the workpiece or the milling cutter does the feed motion. Milling machining aluminum parts cuts the metal material on the surface of the workpiece into chips through the cutting of the cutter edge and the pushing of the cutter face. Milling machining aluminum parts is different from traditional carbon steel machining. Because aluminum alloy has low hardness, high viscosity, easy cutting, and large plastic deformation, therefore, milling machining aluminum parts requires high-speed equipment, high speed heavy cutting to improve efficiency, reduce plastic deformation, to avoid the thin wall cutting and tearing phenomenon.

The perfect ISO9001: 2008 quality system certification to ensure product quality. The quality personnel perform dimensional measurements on each piece of CNC machined parts. Measuring instruments: Digital caliper, Micrometer Calipers, height gauge, Profile projecto. Measurable accuracy of 0.01mm. In order to improve the speed of inspection, the engineers designed sophisticated auxiliary fixture. We provide dimensional reports of machined parts.

|

Business content |

CNC miliing, CNC turning |

|

Machining Processes |

CNC Milling, CNC Turning, CAM Programming, Sheet Metal Fabrication, Grinding, Cutting, Thread Turning, Milling Threasing, Tapping, Drilling, Knurling |

|

Machining Metal |

Titanium, Aluminum, Copper, Brass, Bronze, Stainless Steel, Steel, Delrin, Nylon, Neoflon, PTFE, Teflon, Ultem, Torlon, PEEK, Acrylic, PMMA,PC, Polycarbonate, PAI, PPS, PA, PET, PEI, PE, PVC, PP, ABS, PEP, PS, PSF, PI, PMMI, PABM |

|

Parts Size |

Milling Parts ( MAX) : Length 1030mm,Width 800mm, Height 750mm. Turning Parts ( MAX) : Diamter 680mm,Length 750mm. |

|

Tolerance |

0.01mm |

|

Equipment Capabilities |

CNC Machining Center, 3 Axis, 4 Axis, CNC Lathe, Lathe, CNC Turning Centers, Horizontal 8/12-position hydraulic turret, Milling Machine, Grinding Machine, Drill Press, Tapping Center, Rotary Indexer, Punch |

|

Secondary Services of Machining Parts |

Assemble, Plating Zinc Color (Machining Steel Parts), Anodize, Anodize Color, Hard Anodize, Hard Anodize Teflon (Machining Aluminum), Electroless Nicke (Machining Aluminum Parts, Machining Stainless Steel Parts, Machining Brass Parts ), Passivation ( Machining Stainless Steel parts ), Sand Blasting ( Machining Aluminum parts ), Brushed ( Machining Aluminum parts , Machining Stainless Steel parts ), Bluing and Blackening ( Machining Steel parts ), Trivalent Chromium Process ( Machining Aluminum parts ), Welding, brazing, soldering, Centerless Grinding and Burnishing |

|

Sample |

Samples are for free, sample time is 5 days. |

|

Delivery |

Delivery time is 3-4 week, depending on the degree of difficulty of machining parts |

|

file format |

Para-Solid 3D, PDF, IGES, STEP, SOLIDWORKS |

We have a dedicated CNC machining technology team. Actory processes: order review, drawing review, product CNC programming, production planning, machining, quality inspection, packaging and transportation. Our technical staff in the plastic machining processing has accumulated a lot of technical experience, detailed analysis of the product deformation in the machining plastic is given. Almost all workers in the plastic machining process will be manufactured to help the fixture inhibit deformation of the product.

We are looking forward to further contact with you. Have a nice day and thanks for your inquiry!

Shenzhen, Guangdong, China

- Manufacturer

- Gold Supplier

- Platform Certification

- SGS Certification

- The Belt And Road

Send your inquiry to this supplier