1 / 4

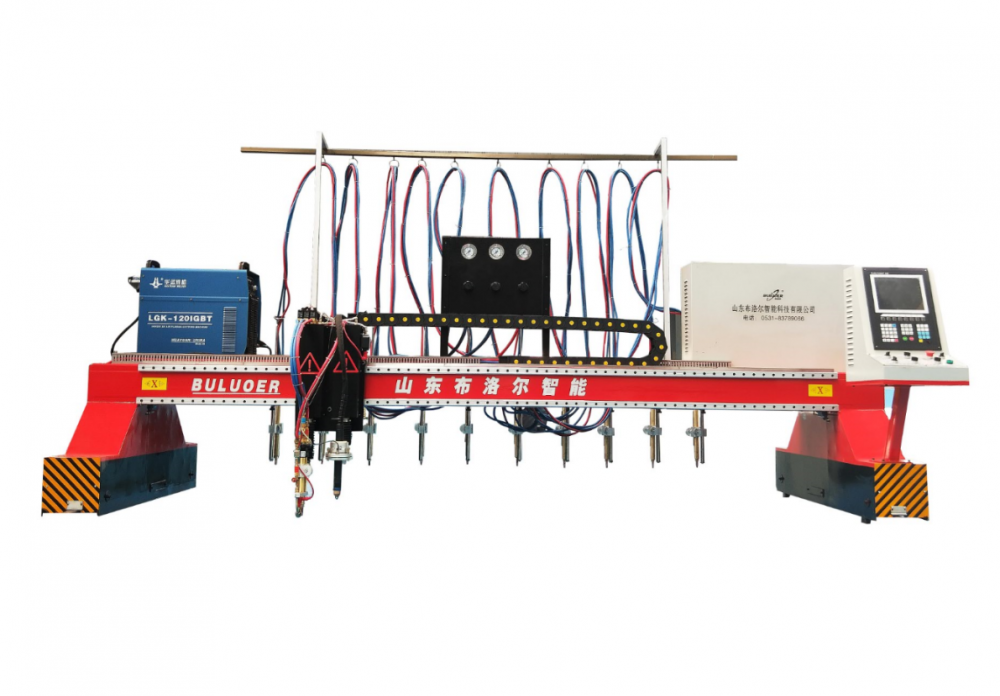

Automatic Ribbon Cutting Machine

| Model No. : | BLZT-4080 |

|---|---|

| Brand Name : | Buluoer |

| Certification : | ISO 9001:2008 |

Jinan, Shandong, China

- Distributor/Wholesaler

- Manufacturer

- Organization

- Retailer

- Service

- Trade Company

- Other

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Video

Product description

In the actual production process, the CNC flame cutting machine often produces the following defects: edge defects, cutting section defects, dross, cracks, etc. There are many reasons for the quality accident. If the oxygen purity is guaranteed to be normal and the equipment is operating normally, what are the main reasons for the flame cutting machine cutting quality defects? Shandong Bloor Intelligent Technology Co., Ltd., as a CNC cutting machine manufacturer for many years, from the torch, cutting nozzle, steel itself quality, steel plate material tells you how to cleverly bypass the quality defects of CNC flame cutting machine cutting. First, the upper edge collapses and presents a vault

Tell you how to cleverly bypass the quality defects of CNC flame cutting machine cutting.

Phenomenon: The numerical control flame cutting machine forms an eaves-like convex collapse on the upper edge of the incision.

the reason:

The equipment preheating flame is too strong;

The height between the cutting tip and the steel plate is too low;

The cutting speed is too slow; the height between the cutting tip and the workpiece is too large, the cutting nozzle number used is too large, and the oxygen in the preheating flame is excessive.

Second, the edge of the CNC flame cutting machine collapsed

Phenomenon: The edge melts too fast, causing rounded corners.

the reason:

The cutting speed of the device is too slow, and the preheating flame is too strong;

The height between the cutting tip and the workpiece is too high or too low;

The cutting nozzle used is too large and there is excess oxygen in the flame.

Third, CNC flame cutting machine drop-shaped beans

Phenomenon: The CNC flame cutting machine forms a string of water-soluble soluble beans on the upper edge of the cutting.

the reason:

The surface of the cut steel plate is rusted or has scale;

The height between the cutting nozzle and the steel plate is too small, and the preheating flame is too strong;

The rigidity between the cutting tip and the steel plate is too large.

As we all know, the CNC plasma cutting machine is an important tool for cutting metal sheets, not only the cutting machine has high precision and cutting speed. Only the cutting thickness will not exceed 30mm, so why can't CNC plasma cutting machine cut thick plates?

The Blol CNC plasma cutting machine uses an air plasma generator as a plasma cutting source. Copper, aluminum, etc. are highly reflective materials (materials that do not easily absorb the wavelength of a CNC plasma cutting machine). Due to wavelength limitation, it is impossible to cut thick copper. Materials such as aluminum, even long-term cutting of this type of highly reflective material, can damage the plasma generator and reduce the overall performance of the CNC plasma cutting machine.

Why can't you cut thick plates for materials that easily absorb the wavelength of the CNC plasma, such as stainless steel and carbon steel? The reasons are as follows:

1. The temperature at the cutting front is low. Due to the cooling of the cutting crack caused by the auxiliary gas oxygen sprayed from the nozzle, the deformation of the cutting crack can be prevented from affecting the workpiece, and the temperature of the cutting front is also affected, so that the thicker sheet cannot be melted, and the cutting or cutting deformation cannot be realized.

2. The auxiliary gas oxygen also has a combustion-supporting effect. During the cutting process, the workpiece chemically reacts with oxygen to form a ferrous oxide layer, so that the surface of the workpiece is covered, so that the diffusion of oxygen is hindered, so that the concentration of oxygen on the cutting surface is reduced to When it is lowered to a certain extent, the burning point of the cutting is suddenly extinguished and cannot be cut, so that the thick plate cannot be processed.

3. The principle of the CNC plasma cutting machine is that plasma cutting is a processing method that uses the heat of a high-temperature plasma arc to melt or partially melt (and evaporate) the metal portion of the workpiece incision, and remove the molten metal by the momentum of high-speed plasma to form a slit. As the thickness of the cutting material increases, the bottom temperature is insufficient to form a through cut.

In order to ensure the safe production of CNC flame cutting machine, Blol intelligently reminds operators of the safety protection measures that must be done:

1. The operator must receive special qualification training according to the regulations and obtain the corresponding qualification certificate;

2. Check the electricity/air source, water source, electricity/air pressure before operation (when the output pressure of the oxygen cylinder is lower than 0.1MPa, replace the new gas in time), and whether the PE line is normal;

3. Check whether there are inflammable or explosive materials (including pipelines with inflammable and explosive gases) within 10 meters on both sides of the guide rail near the equipment;

4. The operator must wear personal protective equipment - work clothes, protective glasses, respirators, etc.;

5, the operator must strictly abide by the general welder, manual gas welding (cutting) safety operation procedures and safety rules for rubber hoses, oxygen cylinders, various industrial cutting cylinders and torch safety operating rules;

It can improve the cutting efficiency and cutting quality of the board and reduce the labor intensity of the operator.

It is the high efficiency flame cutting equipment that adopted the CNC cutting system. Multiple equal slots can be cut at one time and be widely used in steel structure industry with slat cutting. It is a kind of ideal equipment for steel structure plate making.

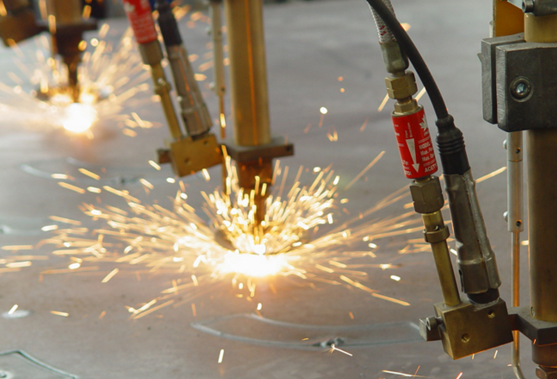

Multiple guns straight line cutting at same time, cutting efficiency is high.

Bilateral drive, high transmission accuracy, operating is stability.

Frame aging treatment, stable structure and non-deformation.

Can achieve the synchronous artificial seat, reduce the labor intensity and reduce the labor fatigue.

Can remote operation, convenient and efficiency, save labor.

Automatic temper control, safety and efficiency.

Jinan, Shandong, China

- Distributor/Wholesaler

- Manufacturer

- Organization

- Retailer

- Service

- Trade Company

- Other

- OEM service

- Gold Supplier

- Platform Certification

- SGS Certification

- Video

Send your inquiry to this supplier