1 / 3

Automatic desiccant filling machine for IGU

| Model No. : | BFG03 |

|---|---|

| Brand Name : | WGM |

| Applicable industry : | Construction Works |

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Product description

APPLICATION of Double And Triple Glass Machinery

The Double Glass Desiccant Filling Machine of Insulating Glass Machine can automatically achieve actions of drilling holes automatically in the insulated glass spacing frames, filling desiccant and sealant. The control system of Double Glazing Machine adopts Germany Siemens, so the speed of filling is quick and stable operation ensure the valid closure property of sealant. The machine improves quality of insulating glass, Igu Process Molecular ieve Filling Machine a necessary equipment in the process of insulating glasses. and the Automatic Desiccant Filling Machine has been approved by CE and with big barrel to save time of changing the molecular thieve.

Main feature of Molecular Sieve Filling Machine

The filling height of can be adjusted according to the size of spacer frame

Filling time can be adjusted

Desiccant auto loading and replenish

Auto drilling, filling and sealing function

Germany Siemens PLC control system

Touching screen interface, simple and visible

Adding glue way is safe and easy

Machine can fill the arc frame.(optional function)

Can fill Molecular sieve diameter 1.0mm-1.5mm(optional function)

Protection device for machine head ((optional function)

Adopt vacuum pump loading device ,increase the loading speed (optional function)

Main technical parameter

|

Filling aluminum frame’s maximum size |

2000mm*2000mm |

|

Filling aluminum frame’s minimal size |

300mm*250mm |

|

Article aluminum specifications |

5.5-24mm |

|

Air source |

≥0.65MPa |

|

Power supply and power consumption |

AC220V 50Hz 1.8KW |

|

Molecular sieve diameter needed |

0.5-0.9mm |

|

Dimension |

1300mm*1100mm*3650mm |

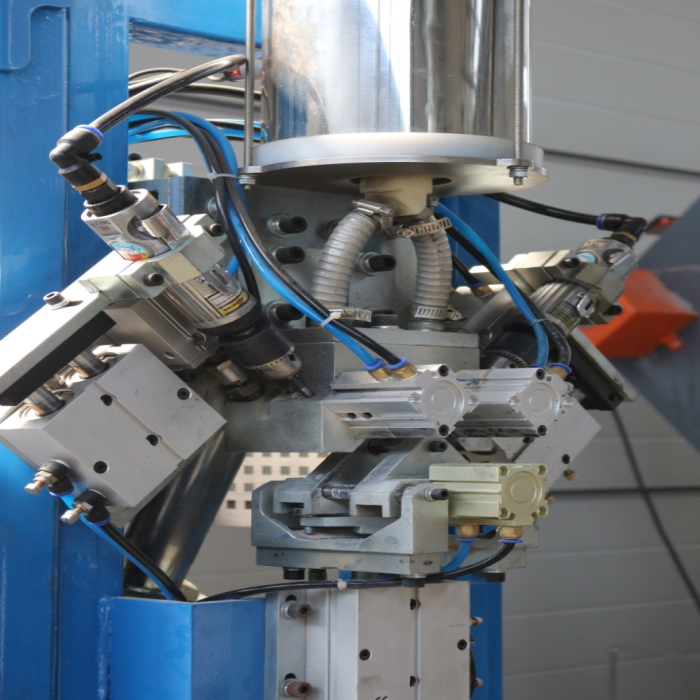

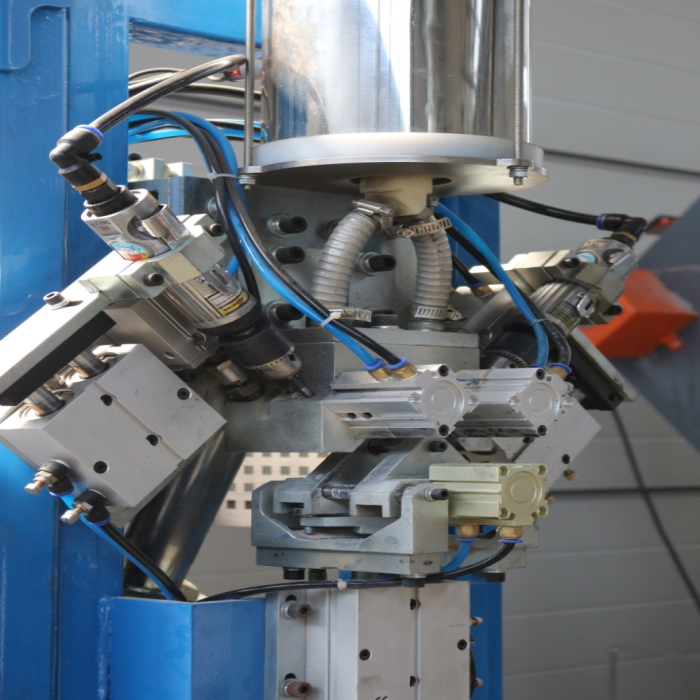

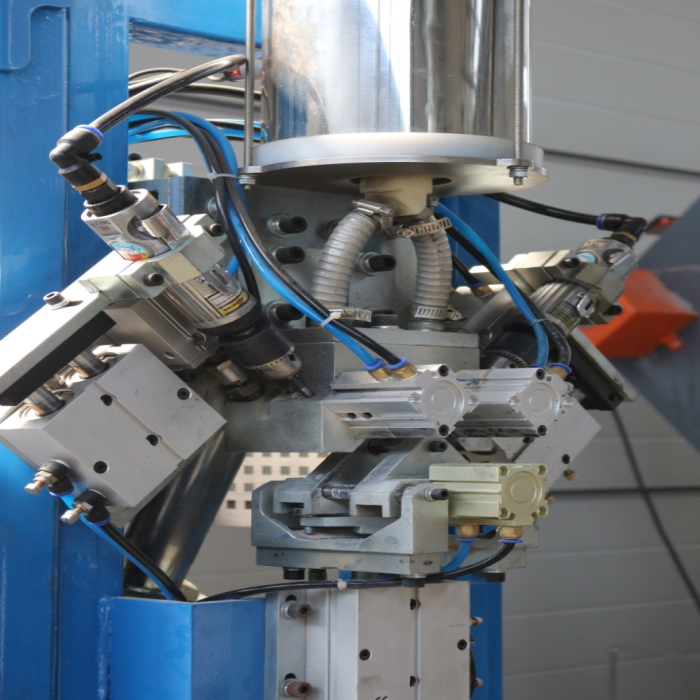

photo details

Jinan, Shandong, China

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

- Online Expo

- Video

Send your inquiry to this supplier