1 / 5

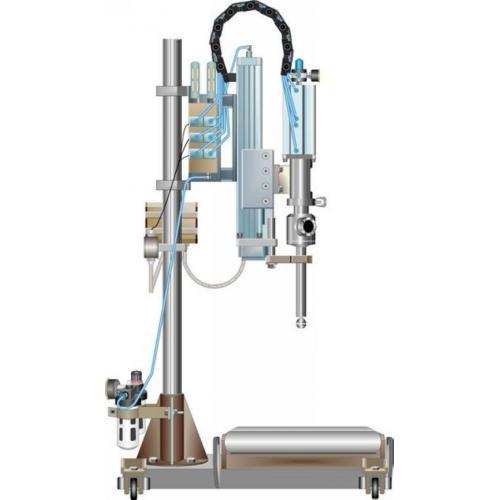

Austrialia Digital Control Liquid Filling Machine By Weight

| Brand Name : | Lude |

|---|---|

| Types of : | Filling Machine |

Changzhou, Jiangsu, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Product description

Description:

The liquid weighing and filling system produced by Lude Company can fill all kinds of containers, including iron drums or plastic drums, and can accurately and quantitatively fill between 1Kg~10000Kg. Auto Bulk Chemical Liquid Filling Machine can be used in damp, corrosive, and explosion-proof environments. Auto Bulk Chemical Liquid Filling Machine has various structures and abundant optional accessories

Features:

As the adhesiveness of liquid materials, the measuring method of liquid weighing and filling generally adopts gross weight type/net weight type, which can reduce the labor intensity of the operator and improve the filling accuracy

Working principle:

After power-on, the power indicator light is on, and the weighing indicator performs self-checking on the indicator. After the self-test is over,if the situation is normal, the indicator displays zero, the scale is empty. It is in the state of waiting for barrel filling. At this time, put the empty barrel on the weighing platform and press the start button. The working process is divided into six steps of weighing judgment on empty barrel, automatic peeling, judgment of spray gun in place, fast and slow double-speed filling, automatic counting and accumulation, and automatic peeling.

Basic Filling Modes:

The filling method is mainly determined by the characteristics of liquid viscosity, bubbles and volatilization

1. It is suitable for filling liquids with low viscosity, splashing and a small amount of foam.

2. It is suitable for liquid filling that generates a lot of bubbles and toxic volatile gas.

Applications:

Liquid filling in petroleum, chemical, pharmaceutical, coating, smelting, food processing and other industries, suitable for quantitative filling of materials with pollution, corrosion characteristics and foaming during filling

Changzhou, Jiangsu, China

- Distributor/Wholesaler

- Manufacturer

- OEM service

- Gold Supplier

- Platform Certification

Send your inquiry to this supplier