1 / 6

3 Liters Dust Resistance Dispersion Kneader

| Model No. : | LN-DP-3.0 |

|---|---|

| Brand Name : | LINA |

| PLC : | Mitsubishi |

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Product description

LINA 3 Liters Dust Resistance Dispersion Kneader

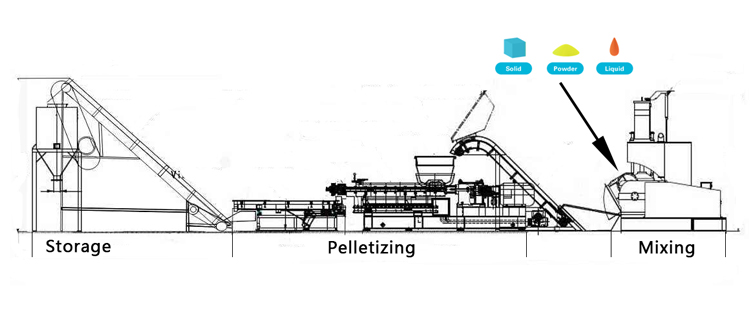

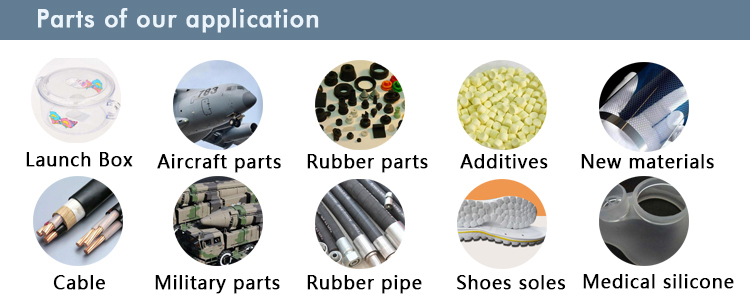

This type of Lab Using Non-Dust Pollution Rubber Dispersion Kneader is designed on the base of Pressurized Dispersion Mixer, and hydraulic and electric flipping types are its main tilting ways, and they can be chose. And the new designed double dust proof device is adopted. LINA 3 liters New Designed Double Powder Proof Dispersion Mixing Machines are surrounded by closed dust proof cabinet and an enclosed space is formed. LINA Double Powder Proof Internal Mixer is suitable for a wide range material including high filling rubber, plastic, elastomers, ceramics and mental, and other powder materials. To ensure the maximum dispersion effect, the specification of rotor, top and down ram is optimized.

Characteristics of LINA 3 L Double Dust Proof Dispersion Mixer

1. Excellent Dispersion Effect: The specification of rotor, top and down ram is optimized to ensure the dispersion effect and material's physical properties reach the best result.

2. The rotor blades are made of imported alloy steel to ensure they are wearable and durable. The rotor shaft is nitrided by 38CrMoAL and HV950-1050 treatment.

3. All surface that has direct contact with the material is sprayed by tungsten carbide. The spraying equipment is imported from Germany. Tungsten carbide alloy is imported, and the wearable level of its surface is 10 times higher than conventional hard chrome plating surface.

4. The kneader is surrounded by closed dust proof cabinet and an enclosed space is formed. Based on the kneader's internal dust collection device, an external dust collection is added, which can avoid powder pollution when feed powder material into the mixing chamber.

Specifications of LINA 3 Liters Powder Proof Dispersion Kneader

|

Item |

Specification |

Remarks |

| Type |

Easy-Cleaning Type |

|

|

Mixing Capacity |

3 liters |

|

|

Production Yield |

2.3-3.8 KG per time |

Subject to the proportion of material and dispersion

requirements. |

|

Main Motor Power |

5.5 KW |

|

|

Flipping Method |

Hydraulic or Electric Flipping |

|

|

Flipping Angle |

110° |

|

|

Temperature Control |

Heating or/and cooling |

Electric/oil/steam heating and circulating water

cooling. |

|

Weight |

About 1200 KG |

|

|

Standard Dimensions |

About 2000*1100*2100 mm |

|

Details of LINA 3 Liters Eco-Friendly Internal Mixer

LINA After-Sales Services

1. On-site installation assistance is available. (There are no charges on installation and trial running, but VISA fees, accommodation fees and transportation fees etc, of the supplier's side are charged by the buyer.)

2. Training of customer's operators and maintenance personnel and long-term technical consultation is provided.

3. One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/components are available. During the warranty period, the supplier, within three hours since receipt of purchaser's notice of any equipment fault, shall provide express solution, and, if necessary, assign service engineer(s) to site across China within 72 hours or site in Pearl River Delta within 5 hours (excluding travel time). Response time for customers overseas shall be agreed upon otherwise based on application for visa and accessibility to the customer's location.

Are you factory or trading company?

LINA Machinery has been engaged in Rubber & Plastic mixing machine for many years. We have workshop and R&D department.

What about the operational guideline?

Training of customer's operator and maintenance personnel and long-term technical consultation is provided.

How about the warranty time?

One year's non-charge warranty period is provided for units in normal operation and long-term spare parts/component are available.

Do you offer the customization of the machine?

Certainly, LINA will give you the most proper recommendation and setting according to your materials and demand.

Dongguan, Guangdong, China

- Manufacturer

- Platform Certification

- SGS Certification

- Video

Send your inquiry to this supplier